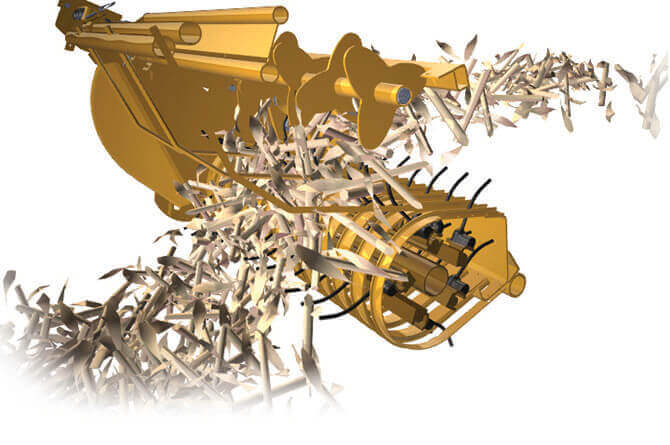

When it comes to durability and efficiency, the new Vermeer 605N Cornstalk Special baler is equipped to bale through even the toughest crop quickly and efficiently. With more heavy-duty components than its predecessor, it’s clear that the 605N Cornstalk Special offers unmatched productivity when baling cornstalks.

It takes a rugged baler with heavy-duty components to withstand the tough conditions and tight time frames of baling cornstalks.

FEATURES & BENEFITS

SPECIFICATIONS

- Bale Diameter 36 in – 72 in (91.4 cm – 182.9 cm)

- Bale Width 154.9 cm

- Maximum bale weight 1088.6 kg

- Length standard 495.3 cm

- Height 297.2 cm

- Width with standard tires 327.7 cm

- Tires 21.5L-16.1 flotation tire

- Weight fully optioned 3900.9 kg

- Drive Roller Size 5.5 in (14 cm)

- Drum roller size 30.5 cm

- Idler roller size 3.5 in (8.9 cm), 4.8 in (12.1 cm), 5.5 in (14 cm)

- Start Roller Size 11.4 cm

- Belt Type Premium mini rough top

- Number of Belts 8

- Width of Belt 17.3 cm

- Length of belt (long) 1371.6 cm

- Length of belt (short) 1353.8 cm

- Type of Lace Alligator rivet

- Silage kit Optional

- Driveline 1000 rpm, extended lube, cut-out clutch

- Torque protection pickup Friction with slip-sensing

- Roller chains Single 50 (60, 80 – O-ring)

- Bearing and Sprocket Configuration Hex shaft and bearings

- PTO horsepower minimum 111.9 kw

- Pickup type Cammed wide

- Width tooth to tooth 195.6 cm

- Width on outside flair 228.6 cm

- Tooth Bars 10

- Number of Teeth (65) double rubber-mounted

- Teeth spacing 3-1/16 in (7.8 cm)

- Stripper bands Steel

- Flotation Gauge wheels – 7.1 – 16 HD semi-pneumatic with spring assist

- Pickup Lift Hydraulic

- Control system type E-Link Pro

- Display 7 in (17.8 cm) color touch screen

- Field Statistics 20 customers with 10 fields each

- Field statistics download USB

- Bale shape indicators Standard

- Moisture Standard – up to 27%

- Bales per hour Standard

- Bale density adjustments Standard

- Density readings Physical gauge

- Cylinder size 3 in (7.6 cm)

- Netwrap system Standard

- Net tension control via mechanical adjustment

- Extra roll storage Standard

- Bale ramp Standard hydraulic; Optional Inline® ramp

- Auto Lube greasing system Standard

- Automatic chain lube system Optional

- Right-hand door Standard

- LED maintenance lights Standard

- Fire extinguisher, safety chain Optional

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com