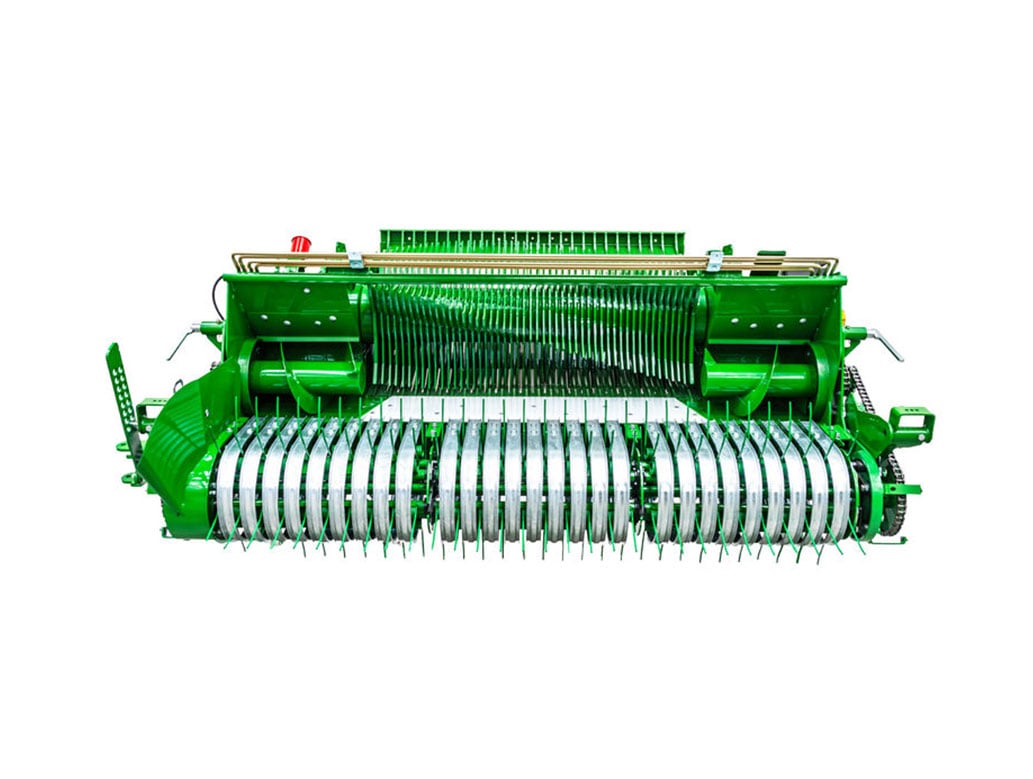

V6760 Fully Automatic Variable Chamber Baler

The McHale Variable Chamber Baler Range is made up of V6, V8 and Fusion Vario machines. The range consists of 7 models;

- V6740 – Non-Chopper Baler

- V6750 – 15 Knife Chopper Baler

- V6760 – Fully Automatic Baler

- V8940 – High-Capacity Non-Chopper Baler

- V8950 – 15 Knife High-Capacity Chopper Baler

- V8960 – High-Capacity Fully Automatic Baler

- Fusion Vario – Integrated Baler Wrapper

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Overview

The McHale V6760 baler is the latest advancement in the variable chamber baler range from McHale. Expanding on the V6 range which produces a bale from 0.6m (2’) up to 1.68m (5’6”) .The V6760 is fully automatic to provide the operator with a high output and easy to operate machine. Utilising the latest technology, the operator simply has to pause on the swath while the machine binds the bale with net before automatically opening and closing the chamber door to eject the bale and resume baling.

In designing the McHale V6760 fully automatic baler, user friendliness was at the forefront of the machine’s development. The 60 series is the highest spec machine in the V6 range and provides the operator with the following functionality:

| Automatic Binding of the Bale | Active Density Control | Additional Drop Floor Unblocking functionality |

| Automatic Tailgate Operation | Intelli-Chamber for a faster bale release | Ability to operate the machine through ISOBUS or an ISO-Play Console |

| In-Cab Net & Density Adjustment | Shape Assist Indicators for more accurate bale formation | Profi-Flo High-Capacity Pick-Up |

Standard Features

| 2.1m Pick-Up | 15 Knife Chopper Feed Rotor | Drop Floor Unblocking System |

| 50 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Centralised Greasing Blocks (Manual Greasing) |

| Continuous Oiling System | ISO-PLAY 7 Control Console | 500/50/22.5 Tyres |

| High Performance Netter | Hydraulic Bale Kicker | 3-Endless Belts |

| Drop Floor Sensor | Mechanical Tailgate Locking | 540rpm Gearbox |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

FEATURES

Intelligent Chamber Control

ICC (Intelligent Chamber Control) consists of Active Density, Shape Sense Indicators, Intelli-Chamber and Active Release technology. These features provide higher output and superior comfort for the operator during the baling process.

Profi-Flo Pick-Up

McHale have created their highest output pick-up for the V6760. The new Profi-Flo pick-up has been designed to increase crop intake through more efficient crop flow and has been engineered to ensure end users are operating with a high-performance pick-up that is designed to suit various working conditions.

Pick-Up

Over the last decade, McHale has designed and developed various types of pick-ups. After extensive testing, McHale decided it will offer customers the choice of 2 pick-up options depending on their working conditions:

Heavy-Duty Pick-Up

The specially designed McHale pick-up is positioned close to the rotor to improve delivery of the crop through the rotor to the bale chamber. Large diameter lateral feed augers help direct crop to the bale chamber ensuring a consistent and even crop flow for producing high density bales.

Adaptive Intake

Over the course of a baling season, machines have to work with different volumes of crop. McHale have designed an adaptive intake which allows the intake area to automatically adjust for light and heavy crops to facilitate a smooth crop flow into the chamber.

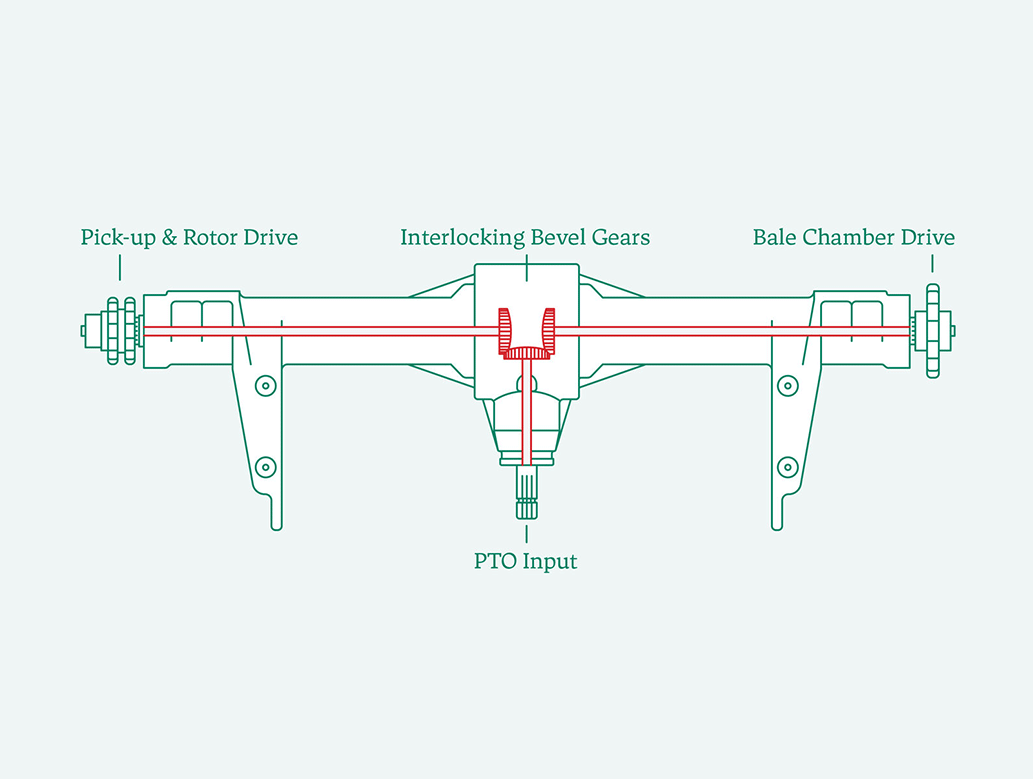

Split Drive GearBox

A 540rpm Split Drive Gearbox is fitted to all machines in the McHale Fixed Chamber Range as standard. The gearbox design ensures that power is evenly distributed to both sides of the machine.

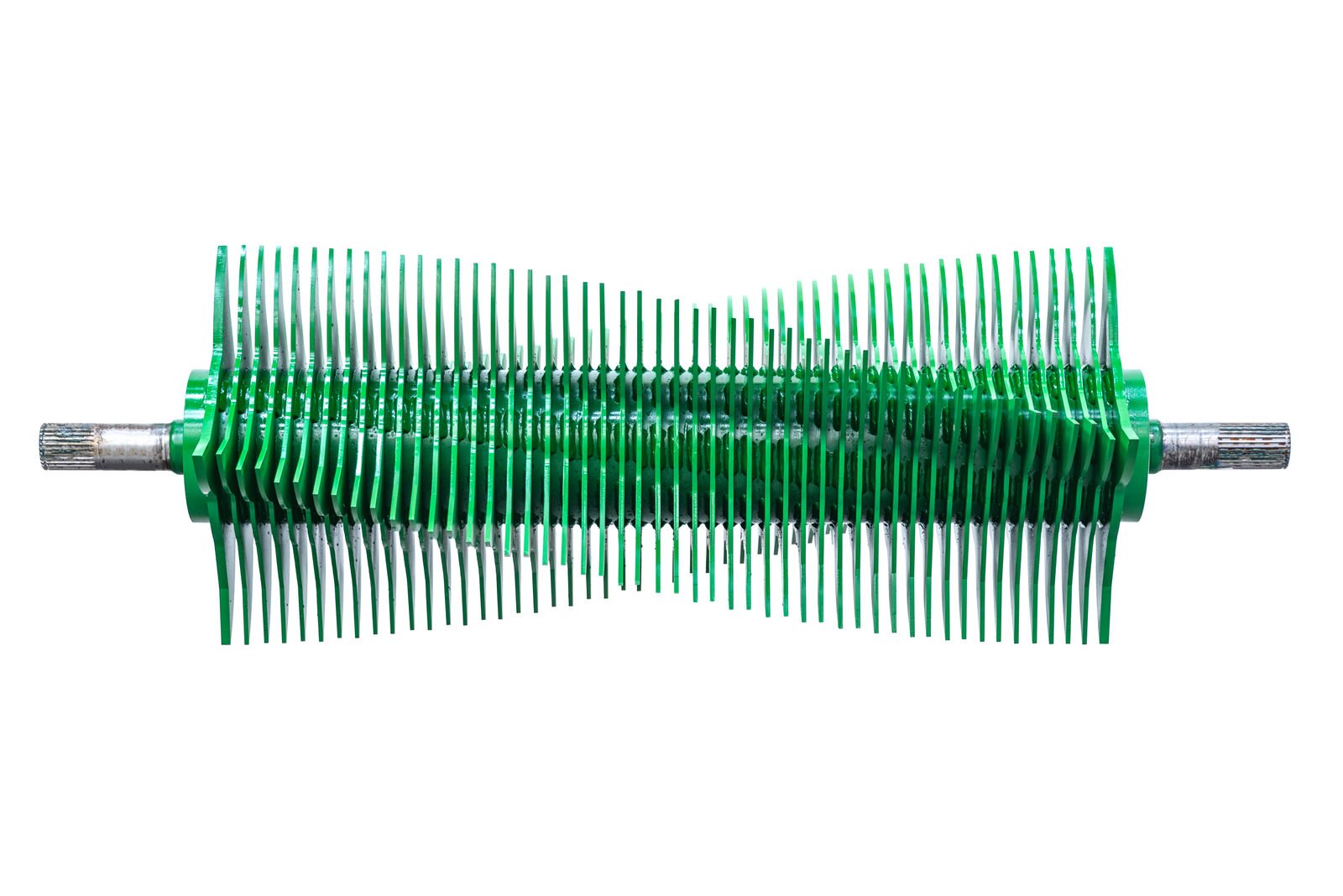

Rotor

The star shaped, twin finger feed rotor ensures a high-capacity flow of crop into the bale chamber.

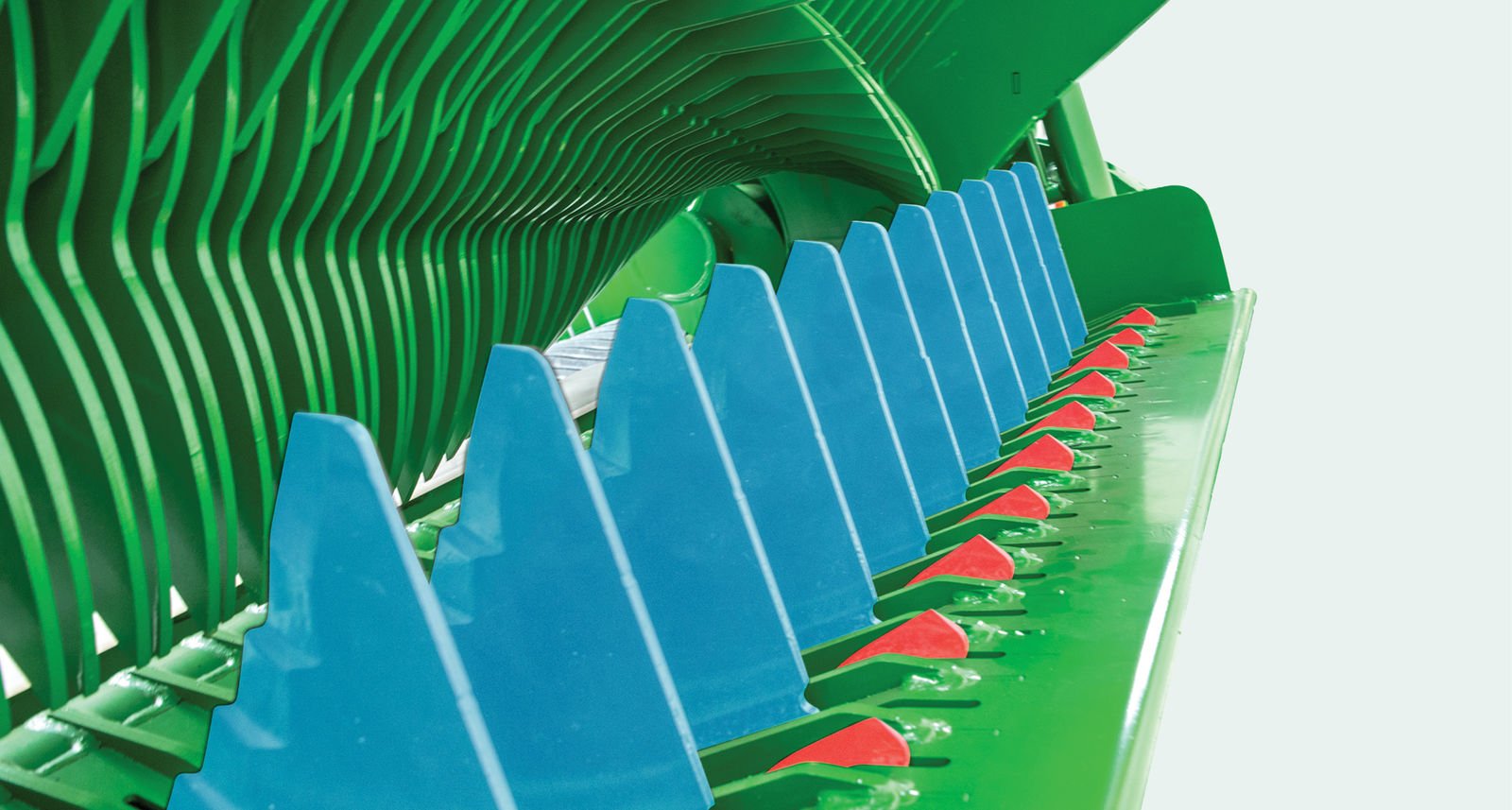

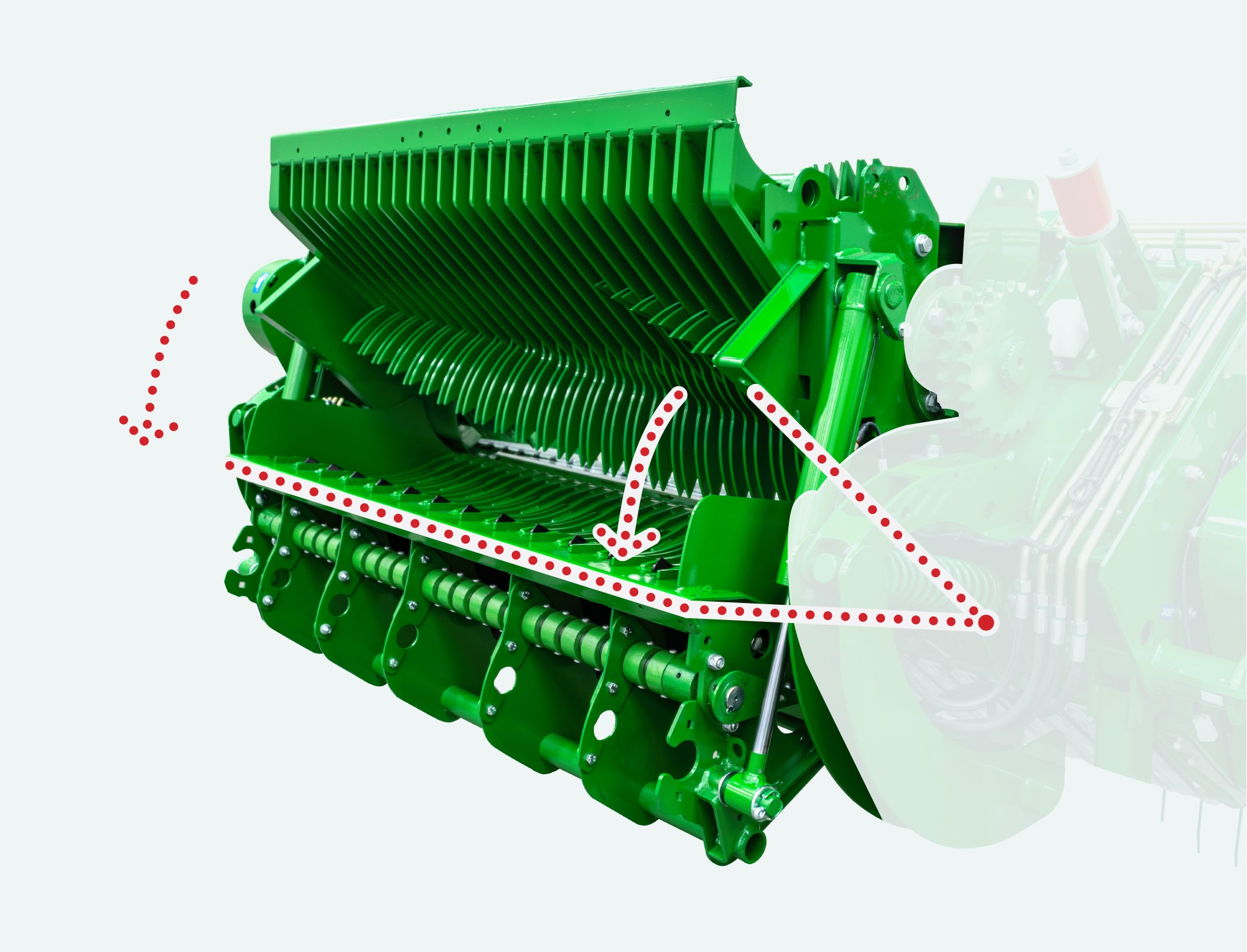

Chopper Unit

To ensure a consistent and even chop quality, two chopping options have been developed for the McHale Variable Chamber Range.

Selectable Knife System

All McHale V6760 machines have the option to be fitted with a selectable knife system. Various knife configurations can be chosen depending on the knife bank specification.

Drop Floor

For over a decade, all machines in the variable chamber baler range are fitted with the McHale Drop floor unblocking system, a feature which operators have come to love for it’s simplicity of use and effective unblocking cycle. When connected to an ISOBUS tractor, the drop floor will automatically lower when the software detects a blockage. Once the operator restarts the PTO and the blockage clears, the drop floor will automatically rise to its original position.

Bale Chamber & Bale Sizes

The bale chamber on the McHale variable chamber baler range is comprised of heavy-duty endless belt(s). The belts are extremely hard wearing and are reinforced with synthetic material, which ensures that the belt(s) can absorb and apply high pressure to the material in the Bale chamber.

Bale Chamber Double Drive

A heavy-duty drive system powers belt and bale rotation on all machines in the variable chamber baler range. On the McHale V6740, a primary drive system is fitted to ensure belt rotation and bale formation.

Oiling & Greasing

The McHale fixed chamber range of balers are all fitted with a continuous oiling system. Once the PTO is engaged, the continuous oiling system constantly lubricates the chains to ensure a long lifetime. A lube alarm sounds after 300 bales to inform the operator to refill the oil tank.

High Performance Netter

A high performance netter has been designed and developed for the McHale Variable Chamber Baler Range. This netter is very reliable and comprises of a moving roller which allows the roll of net to rotate as it is being applied to ensure even net application.

ISO-PLAY 7 Control Console

The McHale V6760 is fitted with an ISO-PLAY 7 Control Console, which has a large graphic display.

Options

McHale machines work in different conditions around the world. To optimise performance, we offer a number of options in the McHale variable chamber range. We recommend you speak with your local dealer/distributor as regards the best configuration to meet your requirements

SPECIFICATIONS

| Length | 4.8m (15’ 9”) |

| Width |

2.54m / 2.58m* (8’ 4” / 8’ 6”)* |

| Height | 2.75m (9’) |

| Weight |

4,600kg (10,140 lbs)* |

| * Value will vary depending on specification | |

| Working Width | 2100mm (6’11”) |

| Pick Up Guide Wheels | Standard |

| Crop Roller | Standard |

| Short Crop Guard | Optional |

| Tine spacing |

67 mm (2⅝”) 55 mm camless (2⅛”) |

| Tine Bars | 5 (6 on Camless Pick-up) |

| Number of Knives | 15 |

| Theoretical Chop Length | 65mm |

| Knife Protection | Hydraulic |

| Knife Deactivation | Hydraulic from Cab |

| Unblocking System | Drop Floor |

| Diameter | 0.6 m (2’) to 1.68 m (5’ 6”) |

| Width | 1.23m (4’) |

| Bale Chamber Feed | 15 Knife Chopper Feed Rotor |

| Number of Belts | 3 |

| Net Adjustment | In Cab |

| Net System | High Performance Netter |

| Net Roll Capacity | 1+2 Storage |

| Control | Manual or Automatic |

| Gearbox | Split Drive |

| Main Drive Protection | Cam Clutch |

| Pick – Up Protection | Slip Clutch |

| Chain Lubrication | Continuous |

| Bale Chamber | Double Drive |

| Control System | ISOBUS / ISO-Play |

| Operation | Fully Automatic |

| Density Adjustment | In Cab |

| Bale Size Adjustment | In Cab |

| Inbuilt Camera | 1x In-built Camera |

| Axle | 8 Stud |

| Brakes | Option: Air / Hydraulic |

| Tyres Standard | 500/50/22.5 |

| Tyres Optional | 560/45/22.5 |

| Bale Kicker | Hydraulic |

| Road Lights | Standard |

| Minimum Hydraulic Flow | 30 l/min @180 bar |

| Hydraulic System | 2 double acting spools, 1 free flow return |

| Electronics | 12 Volt DC, 20 amp |

| Minimum PTO Requirements | 60 kW (80hp) |

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com