McHale Pro Glide F3100 Front Mower

Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

Overview

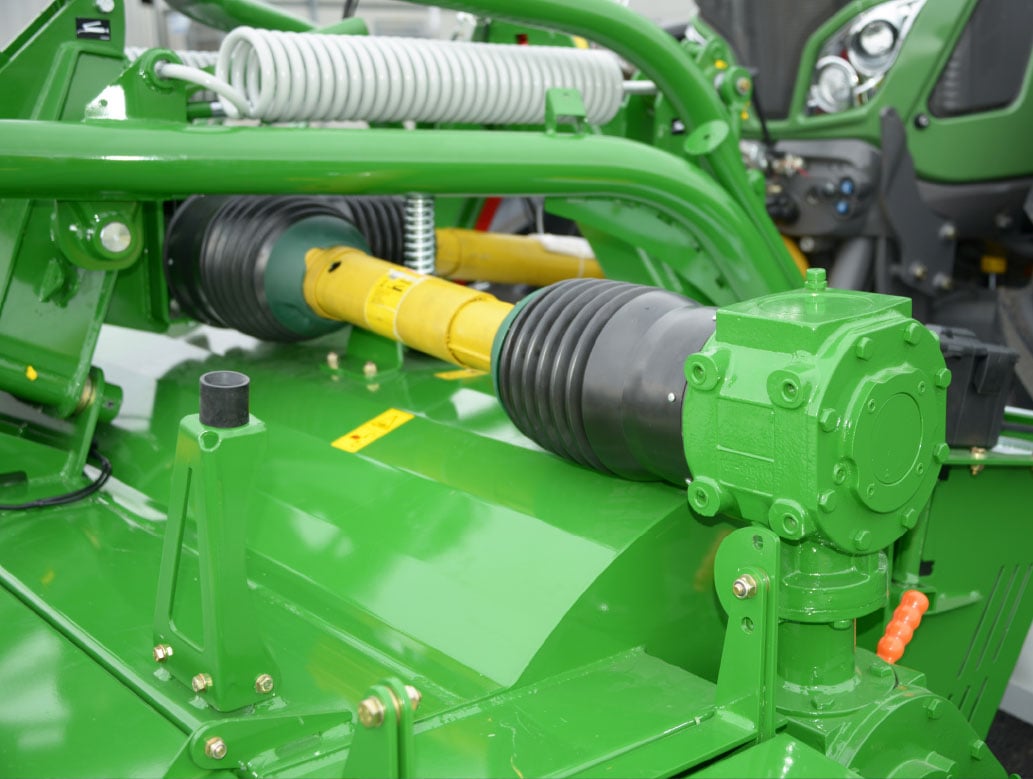

The McHale Pro Glide F3100 Front Conditioner Mower suspension allows the cutter bar to move independently of the tractor’s linkage.

The McHale patented spring compensator ensures that cutter bar ground pressure is maintained over the 500 mm Vertical Travel Range and the cutter bar angle automatically adjusts up & down to the changes in the ground conditions

Standard Features

| Tubular Frame with Integrated Suspension Design | Springs Provide Excellent Ground Following Ability | Automatic Bed Angle Adjustment |

| Patented Constant Ground Pressure | 17º Transverse Movement (Left / Right Movement) | 500mm Adaptive Range (Up / Down Movement) |

| Excellent Headland Height Clearance of Over 600mm | Foldable Guards Give Optimum Access to the Cutter Bar | Narrow Transport Width Provides Excellent Visibility |

| Pull Type Mowing System | ||

FEATURES

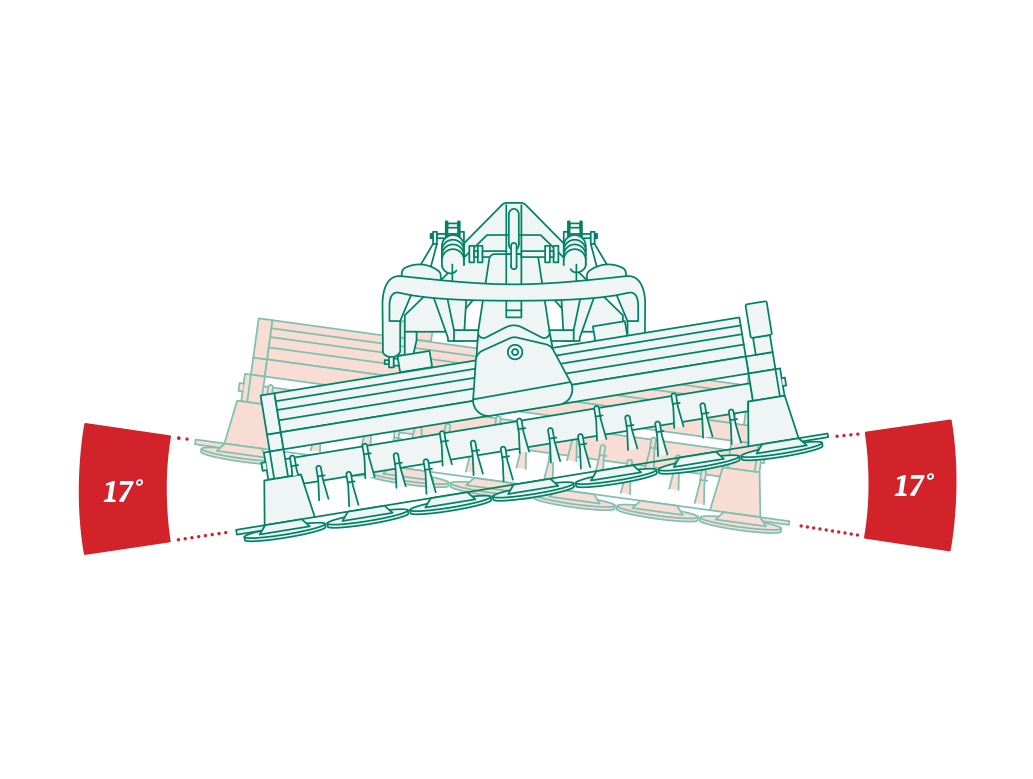

Transverse Pivot Range - 17°

A Transverse pivot range of 17 degrees allows the cutter bar to follow right to left or left to right changes in ground conditions, without overloading the cutter bar. When faced with an incline or decline in ground conditions the cutter bar automatically adjusts its mowing angle by inclining upwards over bumps and slants downwards into dips which ensures unrivalled cutting performance.

Vertical Working Range - 500mm

The Pro Glide front mower has its own independent suspension, which allows the mower to automatically move up & down independent of the tractor and has a vertical travel range of 500 mm.

Independent Movement

The integrated suspension allows the mowing unit to move completely independently from the front linkage. This guarantees the best possible pattern of movement of the mower unit by allowing the cutter bar to immediately respond in an up and down, or left and right motion to changes in ground conditions.

Centre of Gravity

McHale’s design team have designed the frame on the Pro Glide front mower to place the centre of gravity as close as possible to the tractor, which results in unrivalled responsiveness to changes in conditions. The support frame on the mower responds to uneven terrain to glide over the ground through the use of an integrated suspension.

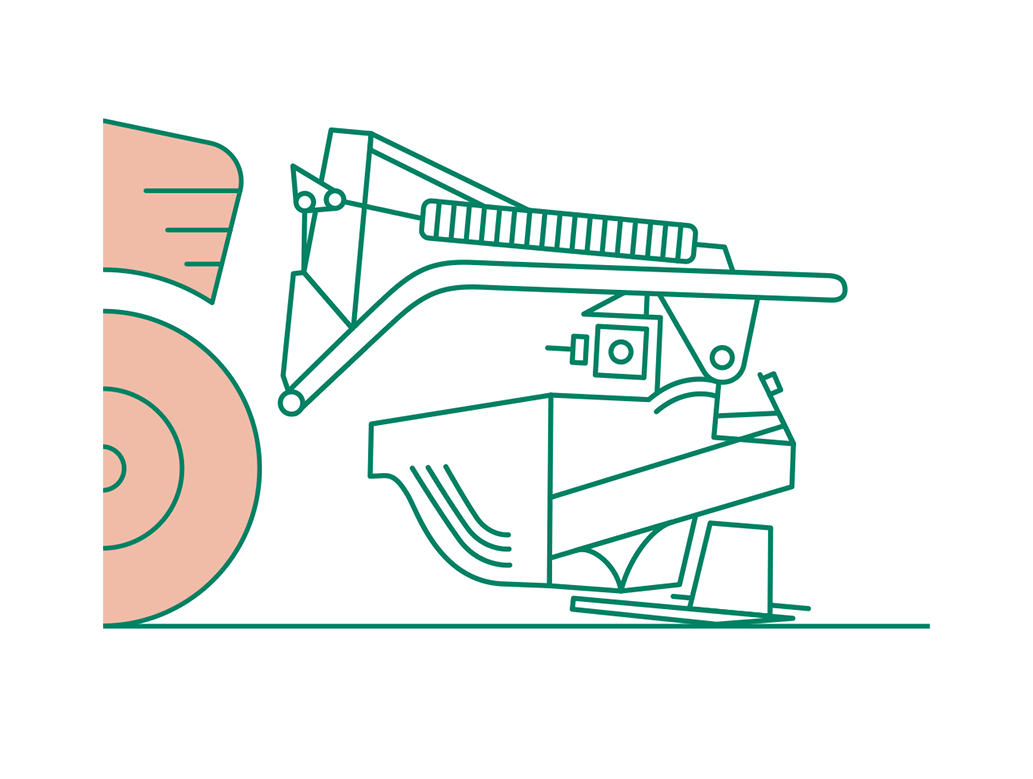

Patented Active Spring Compensator

The McHale Pro Glide front mower range is fitted with patented active spring compensator technology which ensures that the mower cutter bar always applies the same ground pressure regardless of the working height. When the ground pressure is set on the springs as the mower travels downward the patented active spring compensator controls the spring tension and ensures that the weight of the cutter bar on the ground is kept uniform regardless of the working height

Cutter Bar

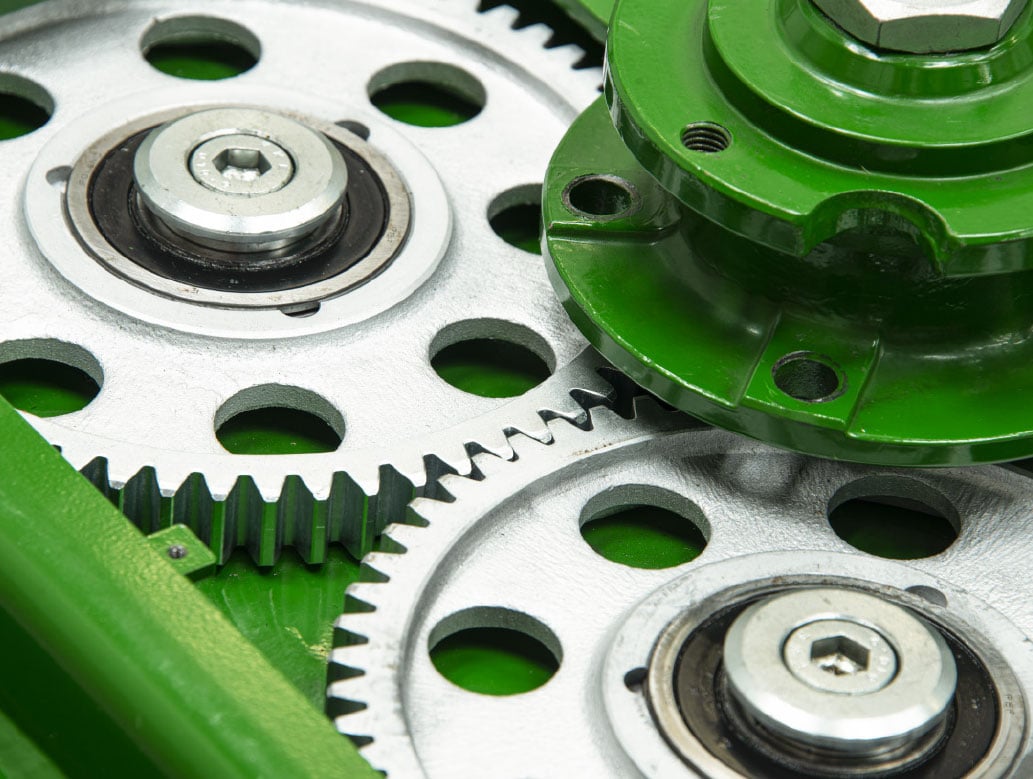

Pro Glide mowers are fitted with an extremely strong fully welded cutter bar. All 3m cutter bars are fitted with 7 discs while all the 3.4m cutter bars are equipped with 8 discs. The discs are driven by auxiliary gears and as the cutter bar is welded and filled with oil, the gear drive operates in a continually lubricated environment which ensures quiet operations and maximum life.

Cutter Bar Drive

The Pro Glide cutter bar is directly powered by a heavy duty right angle gearbox that is positioned behind the inner mowing disc to allow the operator mow into corners and over rough terrain without experiencing problems. Compared to using belts, which can slip in heavy crop, direct drives ensure even and continuous distribution of power across the gears in the cutter bar.

Low Profile Front Edge

The Pro Glide cutter bar has been designed so the rounded low profile front edge lets the fully welded cutter bar glide smoothly over the ground. The slanted leading edge of the cutter bar allows for clean forage separation and reduces ground contamination.

Heavy Duty Design

In the cutter bar, large heavy duty drive gears transfer the power to auxiliary gears which power the individual discs. The auxiliary gears which drive the individual discs are mounted in a forward position on the cutter bar which deliver maximum cutting performance even when working in lodged crops.

Discs

The mowing discs are specifically designed to maximise crop flow. All mowing discs are equipped with two blades that are angled to ensure a clean cut. The blades orbit with a generous overlap to deliver an uncontaminated swath. Each mowing disc has its own individual protective safety mechanism, if a collision occurs, the mechanism will shear in order to protect the drive.

Blade Overlap

The 110mm mower blades rotate and overlap very close to the surface of the cutter bar and the counter blade to deliver a clean cut. With the aid of the specially designed lever, the blades on the McHale Pro Glide mower can be changed quickly and easily. A weatherproof toolbox is mounted on the mower for storing spare blades and tools.

Steel Tine Conditioner

The McHale Pro Glide comes standard with a steel tine conditioner to condition the grass as efficiently as possible. In order to increase wilting time and decrease the exposure of the forage to the weather, the McHale Pro Glide prepares a uniform swath by conditioning across the working width of the mower.

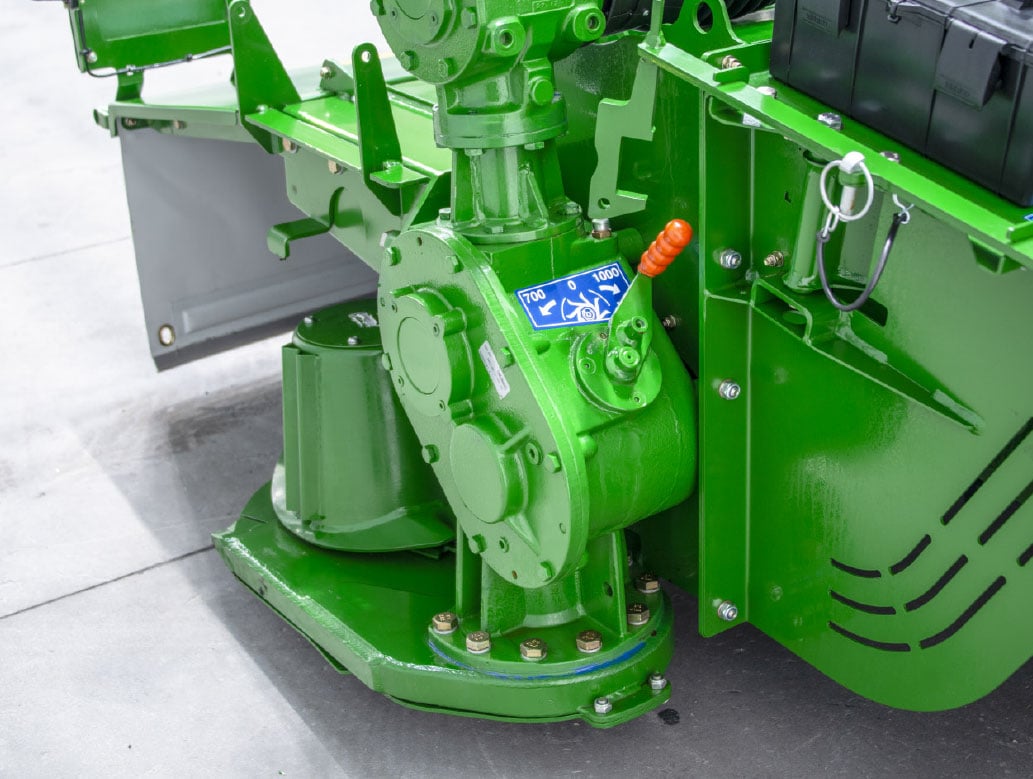

Conditioner Drive

The conditioner is driven by a mechanical gearbox. Conditioning speeds can be adjusted between 700 and 1000 rpm with the simple pull of a lever. The position of the steel tines allow for powerful conditioning, which ensures the McHale Pro Glide range can deliver fast uniform wilting. Should a tine come into contact with a foreign object they pivot out of the way.

Swath Width

The operator can select from six adjustments for adjusting conditioning intensity. The operator also has the option to set the deflection plates and leaves the swath in a wide or narrow formation.

Drive Line - 1000 rpm

The McHale Pro Glide mower range is fitted with a heavy duty 1,000 rpm drive line. Power is transmitted through heavy duty star tubing and the shaft is protected by the Walterscheid P Line range of drive shafts. These drive shaft covers allow for very easy and simple access to all greasing points without the need for any untidy anti-rotation chains on the shaft guards and results in improved operator safety by delivering a longer service life.

SPECIFICATIONS

| Transport Width | 2.94m (116′) |

| Transport Length | 1.98m (78″) |

| Transport Height | 1.45m (57″) |

| Weight | 1,250 kgs (2,756 lbs) |

| Cutting Width | 3.05 m (120”) |

| Swath Width | 1.3m – 2.3m (51″-91″) |

| Number of Cutting Discs | 7 |

| Total Number of Blades | 14 (2 Blades per Disc) |

| Cutting Height | 25mm – 75mm |

| Cutting Disc Speed | 3,200 rpm |

| Cutting Blade | Quick Change |

| Hydraulic Width Adjustment | N/A |

| Conditioner Type | Steel Tine Conditioner |

| Conditioner Speed | 700 / 1000 rpm |

| Minimum Power Requirement | 80 kW / 108HP |

| Linkage Attachment | CAT II-3 Point Linkage |

| PTO Speed | 1,000 rpm |

| Lighting | LED Lighting: 12 V/7-pin socket |

| Hydraulic Systems | Single Acting Hydraulic Supply with Float |

| Minimum Pressure | 180 bar (2,3610 psi) |

| Minimum Hydraulic Flow Rate | 20 l/min (4.54 gal/min) @ 180 bar (2,610 psi) |

| Capacity | 3.5 ha/h (8.5 acres/hour) |

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com