991 High Speed Twin Dispenser Round Bale Wrapper

McHale’s round bale wrapper range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly.

Farmers and contractors all over the world are under pressure to reduce costs and increase output. To help with this, McHale concentrate on features like the patented hydraulic ground supported bale damper system, patented high-speed transfer system, patented tip rollers, hydraulically operated cut & hold system, 750mm dispensers and high specification components.

These features ensure long working life, reliability and a machine rugged enough to handle the toughest crops, heaviest bales and roughest ground conditions.

Overview

The McHale 991 High Speed sets the pace for efficient and effective round bale wrapping, with the hydraulically operated cut and hold system, reducing wrapping time with it’s twin dispensers and Patented Ground Supported Damper System. The 991 High Speed delivers tightly wrapped bales which seal and preserve the crop, with all it’s natural juices, ensuring increased nutritional value. The twin 750mm aluminum dispensers maintain a consistent stretch, which maximises film usage. The dispenser units consist of two aluminium rollers, which are geared to each other with robust steel gears of different ratios. The two dispensers on the 991 High Speed are stepped so that there is an overlap where the two sheets of plastic come together.

Standard Features

| Expert Control Console (Fully automatic cycle) | Auto Load Lift Arm Function | Film Break Sensors |

| Automatic Cut & Hold System | McHale Patented Ground Supported Damper | Capacity to carry 8 rolls of film (6 & 2) |

| 750mm Twin Film Dispensers | Quick Fit Dispenser Film Change | |

FEATURES

Twin Dispensers

Twin 750mm dispensers equipped with two aluminum rollers are paired to each other with robust steel gears of different ratios to maintain a consistent stretch and maximise film usage.

Ground Supported Damper System

The patented bale damper system gently lowers the bale to the ground while eliminating any stress on the chassis of the machine.

Lift Arm & Wrapping Table

The 991 BC and BJS lift arms are operated manually. On the 991 BE and High-Speed, the auto lift function places the bale on the wrapping table automatically.

Extra Film Storage with Easy Handling

The 991 High-Speed can carry 8 rolls of film:

2 rolls (dispensers) + 6 rolls (film storage)

Optional Side Tip

An optional side tip is available on all trailed machines to place bales on their ends after wrapping is complete.

Cut & Hold System

At the end of the wrapping cycle, the hydraulically operated cut & hold system cuts and holds the film in position ready to wrap the next bale.

Automatic Film Break Sensors

Automatic film break sensors monitor the plastic as it wraps the bale. If one roll breaks or runs

out, the operator is notified on screen and the machine switches to single dispenser mode.

Easy Load Dispensers

The McHale lock and load system makes film loading quick and easy by locking the dispenser bobbin up when unloading and locking it back down by simply pulling the cable.

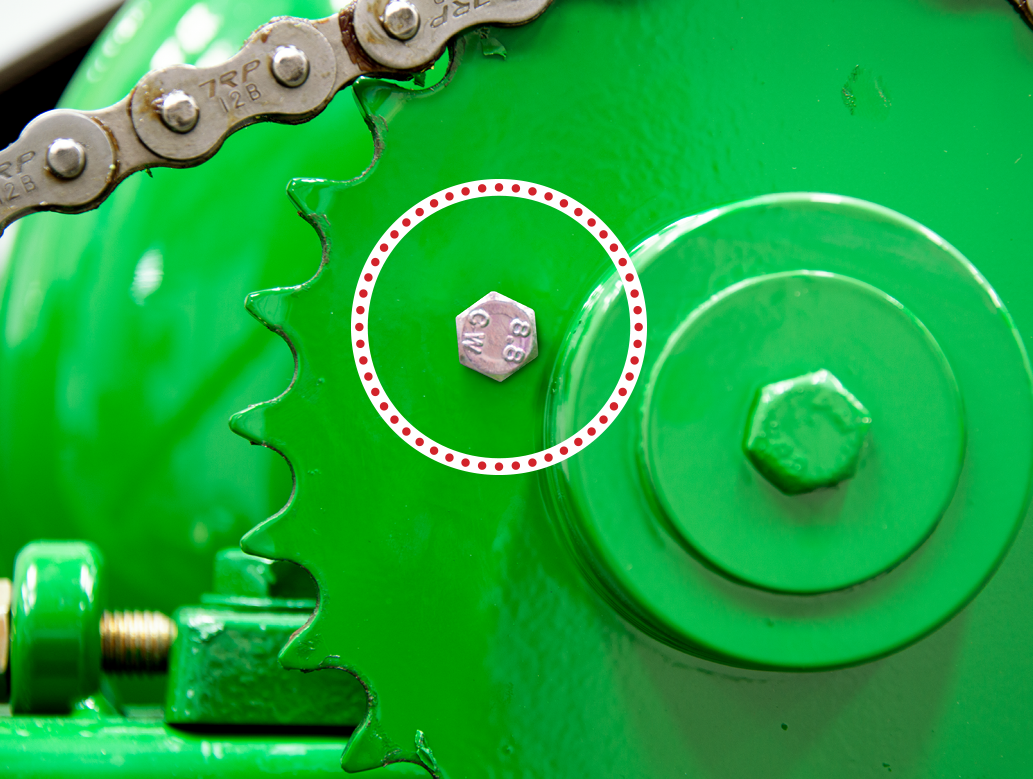

Shear Bolt Unit

A Shear Bolt protects the gearbox when wrapping poorly shaped bales. All machines are now driven by a heavier gearbox than previous models.

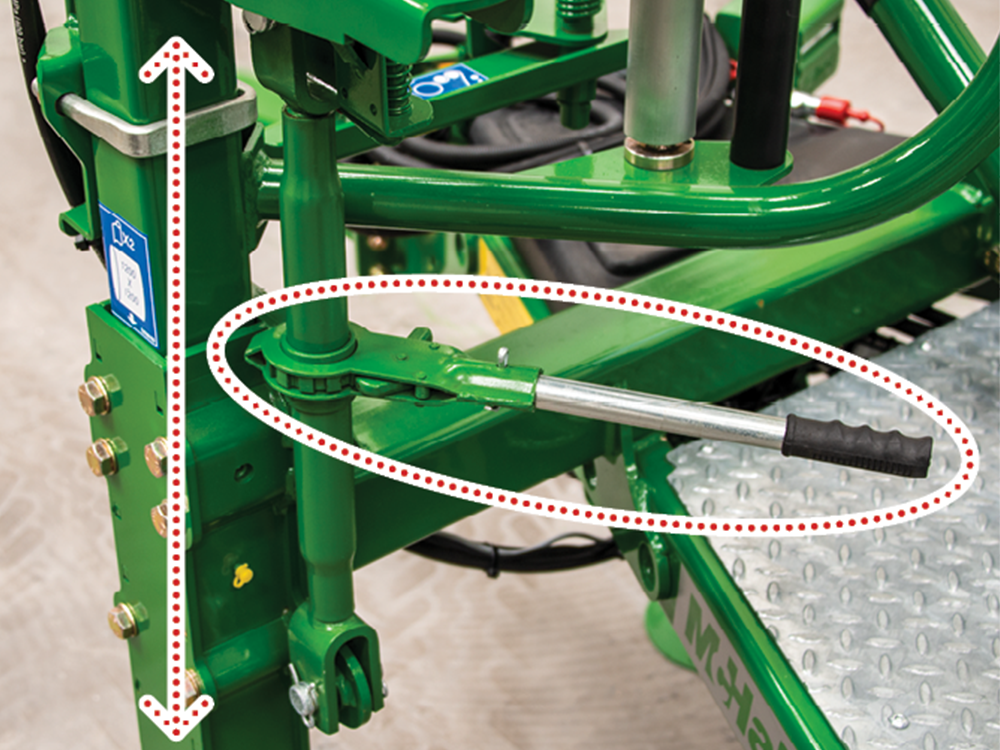

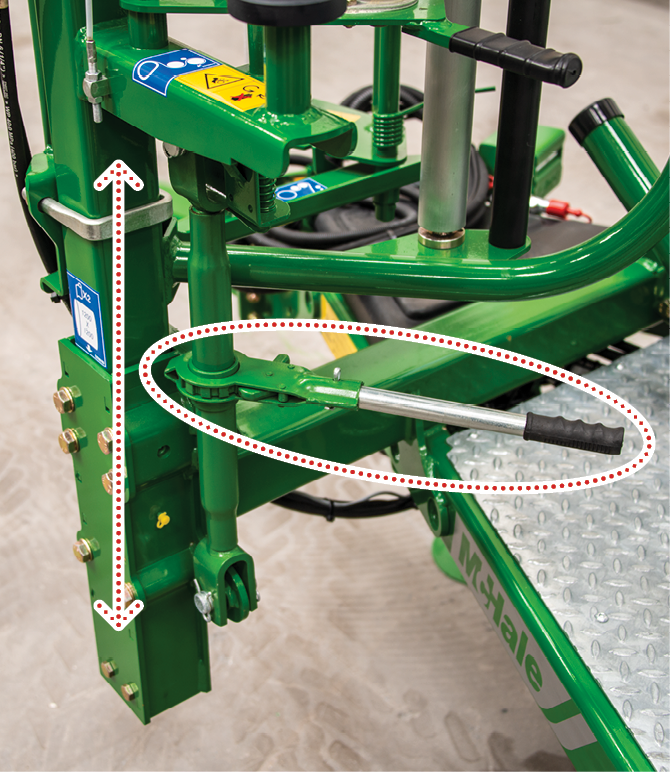

Wrapping with one roll of film

The dispenser post height can be manually adjusted to maximum position using the height adjustment handle.

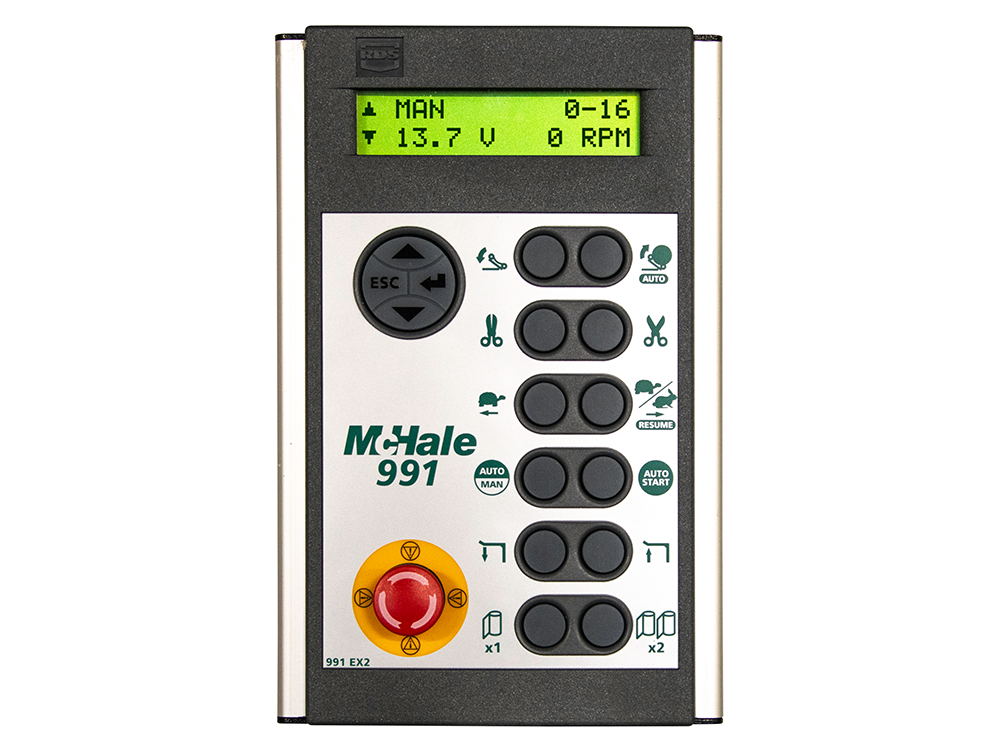

Expert Control Console

The Expert electronic control console fully automates the wrapping process. This user-friendly console provides access to all functions without ever having to leave the comfort of the tractor seat.

Radio Remote Control Kit for Static Wrapping

With a radio remote control kit, an operator can load a bale and activate the automatic cycle remotely.

SPECIFICATIONS

| Transport Length | 5.7 m (18’8″) |

| Transport Width | 2.45 m (8’1″) |

| Transport Height | 2.46 m (8’1″) |

| Height to Top of Rollers | 1.25 m (4’1″) |

| Weight (unladen) | 1900 kg (4189 lbs) |

| Bale Size | 1.52 m (3’3″-5′) |

| Aluminum Dispensers | 2 x 750 mm |

| Film Stretch | 70% Standard

55% Optional |

| Wrapping Speed (up to) | 30 rotations/min |

| Wrapping System | Turntable |

| Protection Mechanism | Shear Bolt |

| Lift Capacity

@ 170 bar |

1100 kg (2425 lbs) |

| Driver Control | Expert Control Console |

| Operation | Automatic & Manual |

| Radio Remote Control | Optional |

| Film Roll Capacity | X 8 (2+6) |

| Cut & Hold | Yes |

| Bale Wrap Monitor | Yes |

| Road Lights | Yes |

| Greasing Points | 20 |

| Wheel Dimensions | Standard: 380/55-17

Optional: 480/45-17 |

| Axle | 6 Stud |

| Attachment to Tractor | Pin Hitch |

| Min. Hydraulic Requirements | 22 l/min @ 170 bar |

| Hydraulic Connections | 2 x 1/2″ QR’s Open or Closed Centre |

| Electrical Requirements | 12v EuroPlug, 10A or Direct from Battery |

| Minimum hp Requirement | 35 kW / 47 hp |

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com