Simple and Affordable

Three models available, the VS 127, VS 135 and VS 143, offer capacities that range from 270 to 480 ft³. To best meet your mixing needs, choose from trailer or stationary models.

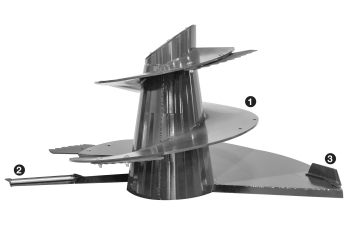

KUHN Knight VSL 200 Series Vertical Maxx® single-auger mixers are designed for small- to mid-sized dairy and beef producers. Two models, ranging from 420 to 550 cubic foot capacities (with extensions), offer the versatility of front, side or rear door unloading. The low-profile design is perfect for quick and easy loading. The proven cone-auger design reduces horsepower requirements, results in more efficient movement of feed and enhances final cleanoff of the auger when unloading.

YOUR BENEFITS

EQUIPMENT

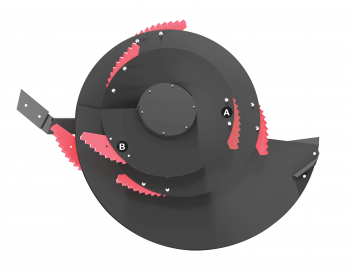

Hay-Retention Ring

The steel hay-retention ring helps contain large round bales during processing and reduces hay spillage more effectively compared to similar options on competitive models.

Side Chain & Slat Conveyor

Optional side conveyors provide the ultimate in durability and long life. Heavy-duty components ensure reliable service, even in extreme use conditions. Multiple conveyor length options offer unmatched flexibility to tailor the discharge to your needs. A fixed tip-off with magnets can be added to catch small metal fragments present in the feed and help prevent hardware disease.

Flat Chain & Slat Front Conveyor – Front

The flat, front conveyor option is simple to operate and offers convenient feeding from either side of the machine on trailer models. Hydraulic side shift is standard and gives you the ability to shift the conveyor a total of 16” from side to side for accurate feed placement.

Incline Chain & Slat Conveyor – Front

The incline conveyor option is available with the choice of either right or left side unloading on trailer models. This option allows the flexibility for both floor feeding and feeding into bunks of various heights where a longer or higher reach is needed for precise feed placement. A fixed tip-off, with magnets, can be added. The magnets work to catch small metal fragments present in the feed and help prevent hardware disease.

Slide Tray

The side-discharge slide tray on the VSL & VT models has simple hydraulic controls and helps guide the feed further away from the tire path. Discharge magnets help catch metal fragments to prevent hardware.

Side Belt Conveyor

An optional belt conveyor can be added for easy and consistent placement of feed at varying heights including the filling of mobile feed carts. The belt offers quiet operation and consistent feed flow. Belt conveyors are able to run steeper versus a chain and slat because you can run the conveyor faster, depending on the materials. The low profile sides allow the conveyor to fold up tighter to the machine for a more narrow transport width. An optional deflector helps with placement of the feed and provides an option for magnets.

Side Chain & Slat Conveyor

Optional side conveyors provide the ultimate in durability and long life. Heavy-duty components ensure reliable service, even in extreme use conditions. Multiple conveyor length options offer unmatched flexibility to tailor the discharge to your needs. A fixed tip-off with magnets can be added to catch small metal fragments present in the feed and help prevent hardware disease.

Side Chain & Slat Conveyor

Different scale brands, models and option are available for all types of operations, ranging from basic to high-end feed-tracking programs. Optional remote indicators are available for placement that will allow easier viewing.

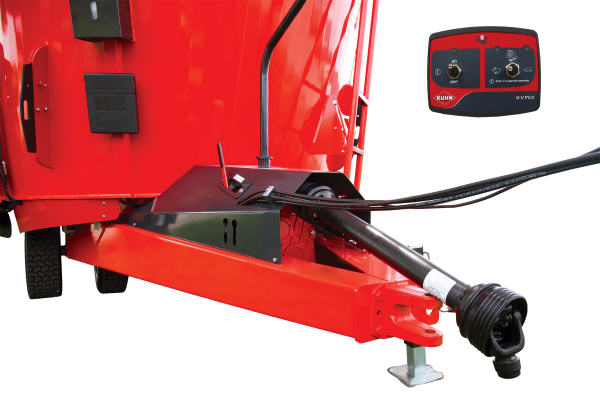

Rear Lift Assist

KUHN offers a 5-year prorated warranty on planetary and 2-speed gearboxes on all vertical mixers. KUHN also offers a 1-year warranty on all other machine components.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com