Fast. Simple. Reliable.

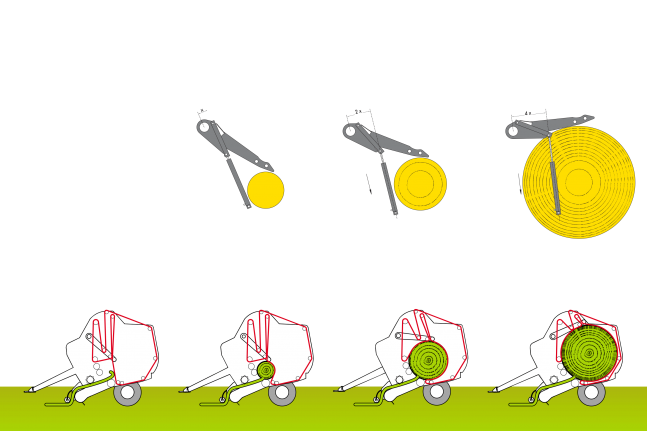

A simple, yet extremely reliable range of variable round balers designed to produce high-quality 4×5 & 4×6 round bales.

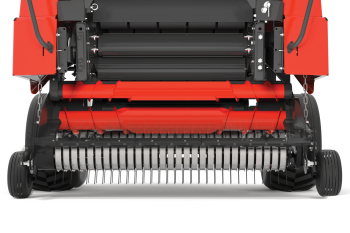

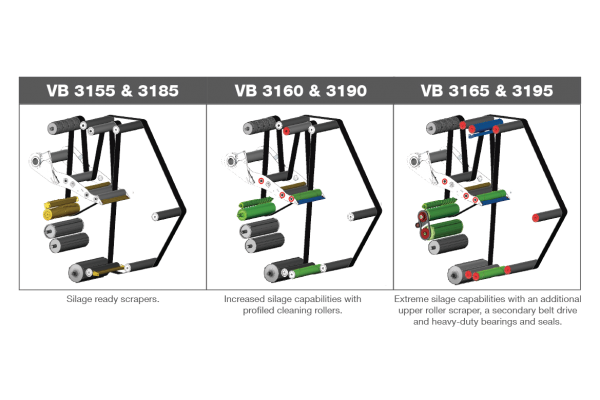

KUHN variable chamber round balers take high-density baling to the next level. Whether you’re a farmer producing a couple hundred bales each season or you’re a custom operator producing thousands of bales, there’s a KUHN VB round baler for you. The VB 3100 Series offers a complete range of variable chamber round balers to suit any size operation, any budget and any type of crop. If you’re looking to bale mostly dry materials such as hay and straw, the VB 3155 and 3185 balers are the right round balers for the job. These models will provide you with the capability and performance you expect, without any extras to weigh you down. The VB 3160 and 3190 Premium round balers work well handling anything from heavy silage to dry cornstalks, with the added convenience of full ISOBUS control. The KUHN VB 3165 and 3195 Premium XD round balers are designed to work in the toughest conditions throughout the world and are ideal for custom operators who need extra density in straw. Built for high-volume hay production, these models feature the most heavy-duty components to keep you producing rock-hard bale after bale, day after day.

YOUR BENEFITS

EQUIPMENT

CCI 1200

The CCI 1200 is our state-of-the art ISOBUS monitor. The 12” color touchscreen has a programmable view. For example, you can see both the camera and the machine user interface on the same screen. It offers wide compatibility with CCI Apps and can be your portal to precision farming. The CCI 1200 comes in a storage box for it to be stowed away securely when not in use.

CCI 50

The Premium VB models are fully ISOBUS compatible. This means the intuitive user interface can be displayed on all VT monitors. The CCI 50 is a full ISOBUS monitor with a 6” color screen. It can be controlled using the touchscreen and/ or the soft keys. A selection of CCI Apps can be used on the CCI 50 to utilize your monitor all year round.

VT 30

The VT 30 monitor controls the baling and tying/wrapping process all from the tractor cab. The 3.5” color screen provides the same user interface as the other KUHN balers, making it an easy to understand monitor for all drivers. The VT 30 is equipped with both touchscreen and soft keys for an intuitive control under all circumstances. It is connected to the tractor using a 3-pin connector.

Productivity at Your Fingertips

The key to achieving the productivity you expect from your KUHN machine, are the user interfaces. We listened carefully to the users of our machines to develop our new user interfaces and monitors. The objective is to have a clear view of what your machine is doing at any time and to have all important settings at your fingertips. This ensures that you have full control of your machine.

Full Visibility

The VB range can be equipped with a KUHN camera system to provide optimal visibility and safety around the machine. There are two kits available, one kit is compatible with the CCI terminal, the other one consists of a separate monitor and a camera.

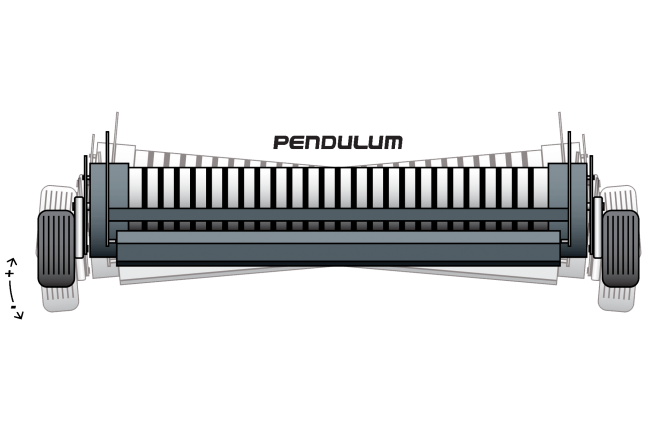

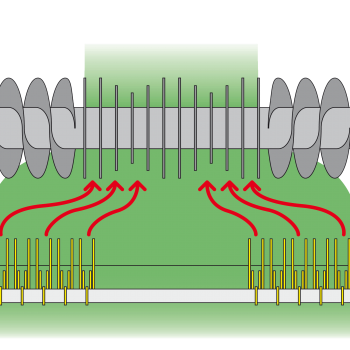

Pivoting pickup wheels

Pivoting pickup wheels allow the pickup to adapt to changing field conditions resulting in less wheel and tire stress

1,000 rpm drive kit

3/8” 21-spline CV for use with larger horsepower tractor.

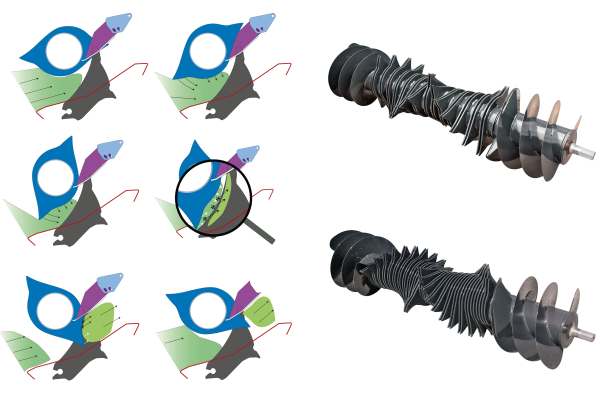

Second Belt Driven Roller

The second drive roller secures bale rotation even in difficult crops (standard on the VB 3165 & 3195).

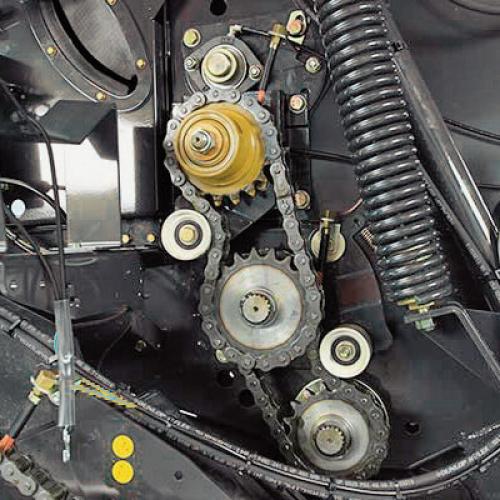

Automatic chain oiling system

A Beka Max continuous chain oiling system allows individual adjustment of the amount of oil on each chain. The sturdy and wide oil brushes on the chains ensure perfect lubrication.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com