Premium Performance that Sets the Standard

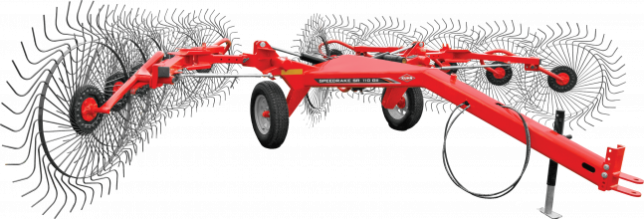

Available in 8-, 10- and 12-wheel configurations, the SR 100 GII Series SpeedRake® wheel rakes feature working widths ranging from 15’10” to 23’4”

Since the first introduction, the SpeedRake® name has been recognized for quality. The KUHN SR 100 GII Series SpeedRake wheel rakes have taken that reputation even further, combining the proven quality, reliability and simplicity that you expect, with next level features to excel even further beyond the competition. Refined styling, higher strength materials and improved options deliver the most value for your equipment dollars. Exclusive in this machine class, the patented windrow adjustment feature allows independent adjustment of the windrow width and raking width to best match specific crop and pickup needs. A built-in mechanical rake arm flotation slot provides superior terrain following without the need for a tractor with hydraulic float. The simple selector valve provides fast, easy switching between transport and field positions to save time and maximize productivity.

YOUR BENEFITS

EQUIPMENT

Kicker Wheel

The optional kicker wheel has a 55” diameter rake wheel, the same size as the main rake wheels, and can be easily raised and lowered hydraulically from the tractor seat.

Tandem Axle

The tandem axles pivot up and down. This is a simple bolt on addition keeping the original tire. They are ideal for smooth and stable operation over difficult terrain.

Windguards

Windguards improve crop flow along the wheels for a more uniform windrow. The durable, HDPE guards are UV stable and improve raking performance in windy conditions. They also reduce wrapping in difficult conditions, such as tall, stemmy crop and corn stalks.

Adjustable Clevis or Ball Hitch

A clevis hitch comes standard with all models. A ball hitch is optional.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com