Your 4-in-1 Solution to Cattle Feeding

Four models available, the SPW 19, SPW 22, SPW 25 and SPW 27, offer capacities that range from 670 to 950 ft3 (19-27 m3).

KUHN SPW Self-Propelled, Self-Loading Mixers combine multiple machines normally involved in mixing and feeding a TMR into a single machine. Four machines are combined into one (silage facer, loader, mixer, power unit) making the SPW the ideal machine for producers looking to increase efficiency in their operation.

YOUR BENEFITS

EQUIPMENT

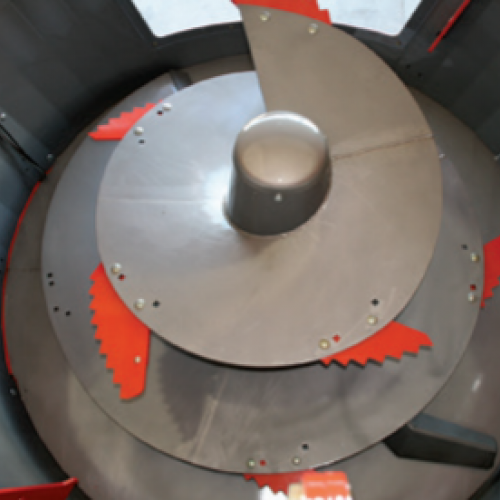

Knife Options

Multiple milling head knife options are available on the SPW. Straight milling head knives are standard on the SPW. Straight milling head knives are optimal for producers looking to not process materials when loading with the milling head. Bent knives are available for producers looking for a higher level of processing while loading.

Auger Knives

No auger knives is the standard option on the SPW. Two combinations of auger knives are available to be ordered, either 5 or 7 knives per auger. High-wear knife options are available in either combination.

High-Wear Mixer Components

High-wear augers

A high-wear auger upgrade is available on the SPW. The SPW utilizes KUHN’s K-Nox high wear material for the high wear augers to provide additional wear life.

Stainless steel liners

30” stainless steel mixing tub liners are available for producers in higher wear applications.

Conveyor Options

The front belt conveyor is standard on SPW machines. The standard conveyor has the capability to offset 10” to either side of the mixer. Front incline conveyors are also optional in addition to the standard front flat conveyor. If optional rear doors are equipped, additional tilting conveyors are available for the rear doors of the machine.

Rear Door Options

Rear side doors are available on either side of the machine to provide additional unloading options in addition to using the standard front door and belt conveyor.

Weighing System

The SPW comes standard with a DigiStar scale indicator to allow third party feed management systems to be used with the SPW.

Road Package

A road performance package is standard on the SPW. Standard road package top speed is 40 km/h (25 mph). Additional equipment in the road package includes a rear axle cooling system, support for the loading conveyor, and a hydraulically operated milling head guard.

Four Wheel/Crab Steer

The standard SPW comes with a non-steered rear axle and only offers front wheel steering. For producers looking for increased maneuverability in tighter locations, four wheel steer and crab steer capability come along with the rear steering axle option.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com