A Heavy-Duty Spreader for a Heavy-Duty Workload

Designed for agricultural and commercial applications that process a wide array of semi-solid and solid materials. With truck and trailer models available, and three discharge options, the PXL 100 spreaders are highly customizable to meet the needs of your operation.

The new KUHN Knight PXL 100 Series ProSpread® apron box spreaders are high-capacity, commercial spreaders that provide producers with a reliable, heavy-duty machine designed for high usage. The PXL 100 Series spreaders, with heaped capacities ranging from 865-1,230 ft³, are KUHN’s largest box spreaders to date, and have been designed for agricultural and commercial applications that process a wide array of semi-solid and solid materials.

All three PXL models are available as trailer models, while the PXL 185 and 1100 are also available as truck-mounted models. With three discharge options, horizontal beaters, VertiSpread® vertical beaters or an AccuSpread® spinner discharge, these spreaders will efficiently spread a broad range of materials giving you the ultimate versatility to match your operation’s needs. This new Series of spreaders also features a rugged tandem or tridem undercarriage, cushioned tongue suspension, guillotine endgate and reversible apron. Save on fertilizer costs by combining your spreader with an optional scale system to monitor application quantities and take maximum advantage of the nutrient value of your manure.

YOUR BENEFITS

EQUIPMENT

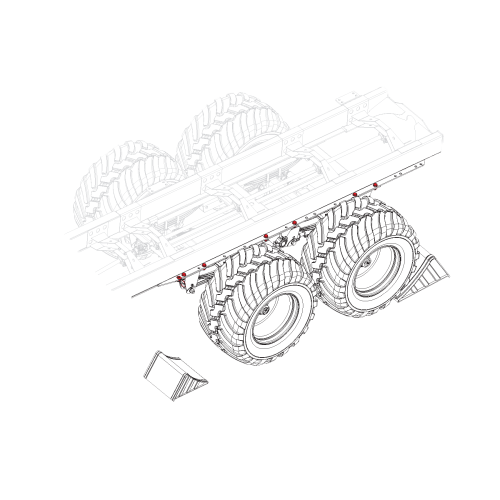

Sliding Tandem – PXL 1100

The PXL 1100 is designed with the capability to mechanically adjust the axle position to achieve the appropriate tongue weight for different applications. The three different axle positions optimize traction and flotation, which is especially important in less than ideal conditions. The design is very similar to the sliding axles on semi-trailers.

Headland Deflector

The optional headland deflector, on models equipped with the AccuSpread® spinner, allows an operator to spread closer to a headland without overlapping an already covered area or spreading over field boundaries. By using the headland deflector, an operator will reduce spreading width from 45-60 feet down to 20-25 feet.

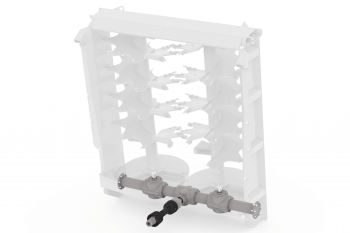

Scale System

A 6- and 8-point scale system allows the operator to accurately determine how much material is in the spreader and how much is being applied to the field. The PXL 185 and 1100 are designed for a 6-point scale system, and the PXL 1120 is designed for an 8-point scale system.

Units equipped with electronic scales can also be fitted with optional scale indicators. These include the TopCon/Digi-Star NT 460 and Digi-Star NT 8000i. These allow an operator to better manage the material they are spreading. The NT 8000i has the capability of controlling apron speed to ensure the spreader delivers a constant rate.

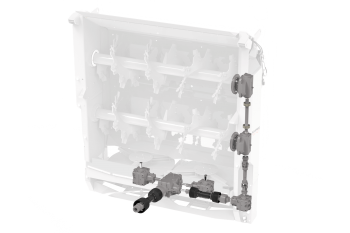

Manual Flow Control

For tractors that don’t have flow control capabilities, the manual flow control allows the operator to easily adjust the apron speed to suit specific materials or speeds. This increases flexibility when spreading a variety of materials.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com