Superior Look, Build & Performance

The KUHN Knight PS 250, 260 & 270 ProSpread® apron box manure spreaders are high-capacity, non-commercial spreaders designed for feeder, cow/calf, and dairy operations that process a wide array of semi-solid and solid materials.

The KUHN Knight PS 250, 260 & 270 ProSpread® apron box manure spreaders are high-capacity, non-commercial spreader designed for feeder, cow/calf, and dairy operations that process a wide array of semi-solid and solid materials. These machines pair superior look and build with performance and are backed by rigorous testing and user feedback. A 10-degree sidewall flare provides greater capacity while still maintaining ease of loading and unit maneuverability. A heavy-duty guillotine gate delivers greater metering capability and material flow management. Choose between horizontal beaters, VertiSpread® vertical beaters and the AccuSpread® spinner module to best fit the needs of your operation. Improved beater location provides an enhanced spreading pattern by streamlining material flow from the apron to the beaters. Additionally, an optional scale system is available for precise monitoring and application tracking.

YOUR BENEFITS

EQUIPMENT

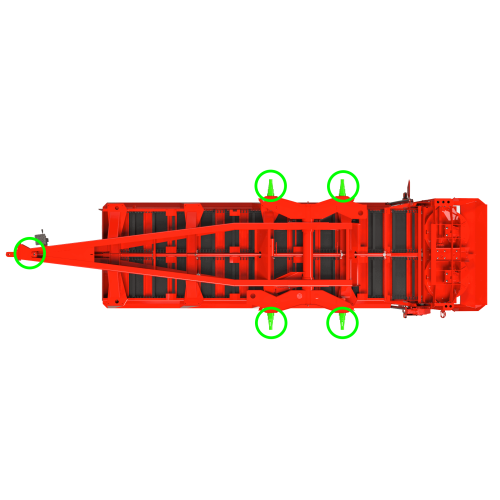

Thrown Object Shield

The thrown object shield, standard with vertical and spinner beaters, better protects the tractor and driver from flying debris. The grated design allows for easy viewing of the unloading process. Optional extensions (shown in the photo) provide greater protection by increasing both height and width.

Choice of Hitch

The PS 250 and PS 260 come with the choice of bolt-on clevis or spade-style hitch without scales and a swivel clevis or spade-style hitch with scales. The PS 270 comes with a choice of swivel clevis or spade-style hitch (as pictured). Both are easily replaceable or reversible for greater service capability.

Adjustable Headland Deflector

A headland deflector allows an operator to spread closer to a headland without overlapping an already covered area or spreading over field boundaries. By using the headland deflector, an operator will reduce spreading width from 45’-60’ down to 20’-25’.

Optional Scales Package

The PS 242-270 can be paired with a scale package which allows the operator to precisely manage and track manure applications. A five-point scale platform provides increased accuracy and durability.

Electric Speed Flow Control

An option for tractors that do not have flow control capabilities, the electric flow control allows the operator to easily adjust the apron speed from inside the cab to suit specific materials or speeds. This provides increased flexibility when spreading a variety of materials.

Manual Flow Control

For tractors that don’t have flow control capabilities, the manual flow control allows the operator to easily adjust the apron speed to suit specific materials or speeds. This increases flexibility when spreading a variety of materials.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com