Spring or Fall, The Optimer XL Can Handle It All!

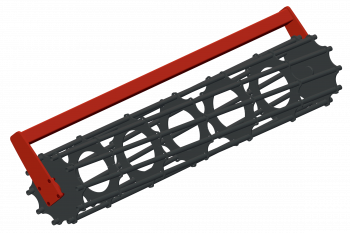

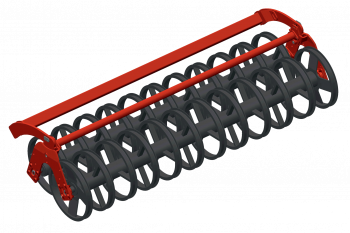

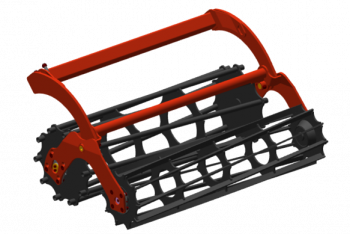

Manage fall residue or create a spring seedbed with the KUHN Optimer XL Series compact discs. Mounted and trailed configurations with a wide range of rear roller options customize the Optimer XL to help suit your needs!

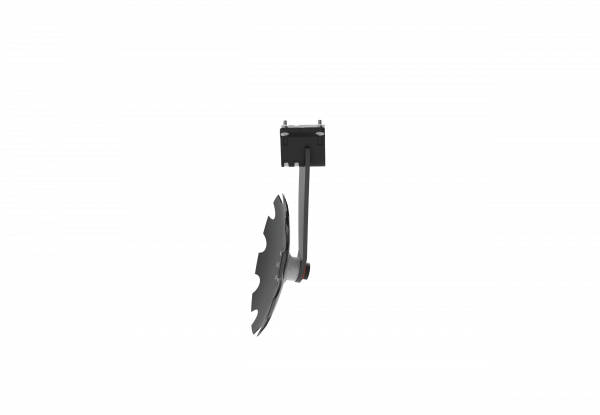

The KUHN Optimer XL is a heavy-duty, high-speed compact disc available in mounted and trailed versions to meet the needs of a wide variety of customers. As a “large-disc” machine with 24” (620 mm) diameter blades, the Optimer XL is best suited for heavy residue and deeper working depths. Each disc blade uses its own suspension arm and elastomer mounting blocks to clear obstacles without upsetting the rest of the blades. Standard mechanical or optional hydraulic working depth adjustment keeps the operator in the comfort of the tractor seat, reducing fatigue and downtime. Several standard features and options including side deflectors, following harrows, and rear roller options help your operation configure the machine to meet your individual needs.

YOUR BENEFITS

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com