In a Class of Its Own

With working widths of 24′ and 30’, and many of the features KUHN mergers are known for, the MM 701 & MM 890 provide operators with the working power of a triple merger in the compact size of a twin.

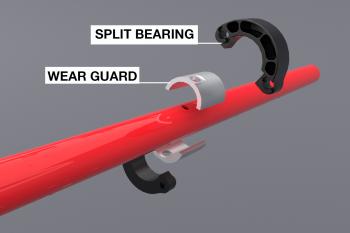

KUHN’s twin hay mergers provide operators with simplicity, versatility, and dependability. The KUHN MM 701 and 890 Merge Maxx® hay mergers offer 24’ and 30’ pickup widths respectively. Designed for mid-to large dairy and commercial forage operations they can merge to the left, right or 50/50 split creating even windrows for the forage harvester. The floating windguard ensures smooth and even windrows to make the forage harvester more efficient, while the crop netting improves leaf retention in the windrow. Simple and durable mechanical flotation on each head eliminates the need to engage float via the tractor’s hydraulics. The IntelliMerge™ ISOBUS control system is an industry exclusive and standard on both the MM 701 and 890, improving operator ergonomics and operational efficiency.

YOUR BENEFITS

EQUIPMENT

Additional Equipment for the Twin Mergers

Auto-Lube Grease Pump

The automatic grease pump is a field installed option and eliminates daily greasing. The grease pump sends grease through the central lubrication system to all of the daily grease points. The central lubrication system and the grease pump reduce maintenance time and keep the machine running efficiently.

ISOBUS Compatibility

To simplify operation with a wide variety of tractors, the MM 701, MM 890, MM 1101 and MM 1301 are ISOBUS compatible for plug and play capability. If the operator has an ISOBUS compatible terminal, they can control all machine functions on that screen. For controlling the machine on a non-ISOBUS tractor, an operator can purchase the VT 30, CCI 50, CCI 800 or CCI 1200 with harness running off a 12V power source. (VT 30 – only MM 701 and MM 890)

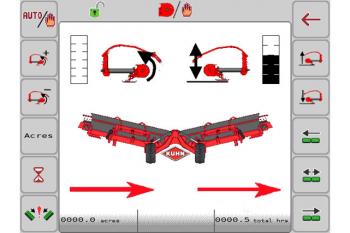

The World’s Only ISOBUS-Compatible Hay Mergers

These user interfaces save you valuable time and money in order to get you in and out of the field faster. Let’s look a bit closer into the heart of the world’s first ISOBUS compatible hay mergers.

- With the electronically controlled speed adjustment system, an operator can quickly and easily adjust pickup speed inside the cab on-the-go to perfectly match crop conditions. With this you can maximize leaf retention, especially if merging drier legumes such as alfalfa. If heavy grass crops, the pickups can also be sped up to promote faster working speeds.

- In automatic mode, the merger will adjust pickup speed automatically as ground speed varies. This maximizes pickup efficiency while minimizing damage to crop and wear of the pickup.

- Acre and hour counters can be used by reading the tractor’s speed and machine width to aid in recording custom operations.

- The electronic conveyor directional control allows operators to rapidly change the direction from all left, all right or split directly from the operator’s seat by simply touching the appropriate key. Operators merging in fields with varying volume throughout may find this particularly valuable.

- Cleanout mode can be activated in the instance of a plugged machine. This feature lets the operator unplug and cleanout the machine from the cab without ever having to leave the tractor cab.

- Pickup efficiency indicates relative capacity of the pickups giving a visual indication to the operator of machine capacity.

- The hydraulically adjustable pickup height allows an operator to easily make changes from the terminal via the skid shoe adjustment. Height change is synchronized and accomplished through a cylinder mounted on each head. Relative height is visible via the gauge on the terminal.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com