Feed the Crop to Maximize Your ROI

The KUHN MDS range of fertilizer spreaders offers a simple and integrated solution for a variety of operations. This includes specialized crops, such as vineyards, orchards and vegetables, as well as row crop and small grain farms.

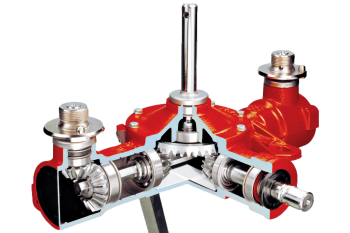

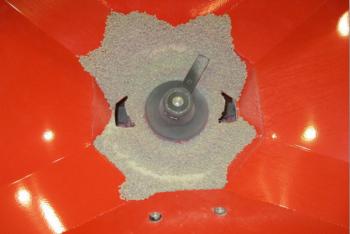

Designed for a wide variety of crop operations, the MDS .2 Series offers many features and options to succeed in almost any application. A simple PTO drive and rugged low-maintenance gearbox operate twin spreading discs that offer working widths up to 80’ (depending on the product applied) to finish large areas quickly and efficiently. Operators will appreciate the increased capacity of the available hopper extensions to work longer between refills, while the octagonal bottom reduces bridging and sticking for even cleanout. Redesigned metering outlet controls offer both electric and hydraulic options and the position of the metering slides can be easily viewed from the tractor seat for improved operator comfort. Optional border control and banding attachments direct product to where it can provide the greatest return on investment – feeding the crop.

YOUR BENEFITS

EQUIPMENT

Hopper Extensions

Several hopper extension options are available to increase the volume capacity of the MDS for spreading lighter-weight materials. On the 14.2 models, it is possible to stack two extension options together for a larger overall capacity increase. Increasing the size of the hopper cuts down on unproductive time spent refilling the unit, allowing more acreage to be spread per day.

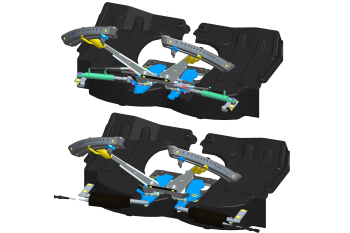

Two Row Banding Attachment

The stainless steel banding option, for applications such as orchards and vineyards, has adjustable flaps that apply fertilizer on two rows of variable width with a spacing that is 100% adjustable. This ensures that all nutrients are applied in the right place near the root area of the crop, saving valuable fertilizer. It can be quickly and easily adjusted without tools.

Border Control

Spreading product outside of the field boundary negatively affects a grower’s bottom line, as that product will never be able to help the crop produce yield. All MDS models offer half-width shutoff and the option of fixed or adjustable boundary spread limiters that physically redirect granules to keep them in the field and out of environmentally sensitive areas. The MDS 18.2 and 20.2 also offer an optional Telimat device that allows for spreading further away from the edge of the field. Border control devices can be moved up and out of the way when full-width spreading is required.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com