Where Innovation Meets Tradition

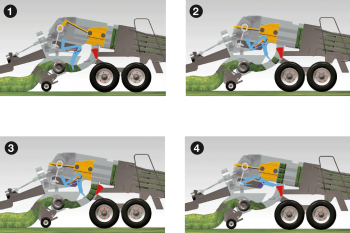

Consistently filled, super-dense, square-edged bales are what every producer demands. KUHN LSB D Series large square balers meet and exceed these expectations, while combining high output and maximum reliability to get the job done fast.

KUHN LSB D Series balers have been built from the ground up to provide you with one of the toughest, most reliable large square balers on the market. The KUHN LSB 890 D (3×3) and 1290 D (3×4) large square balers combine high output and maximum reliability to serve as a perfect fit for commercial hay producers.

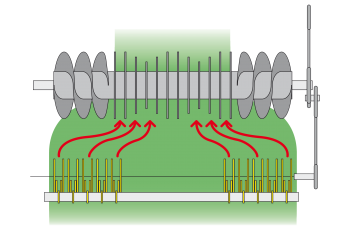

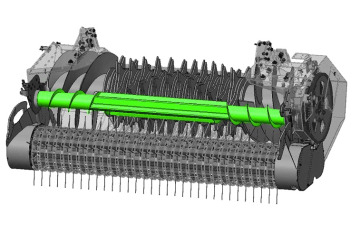

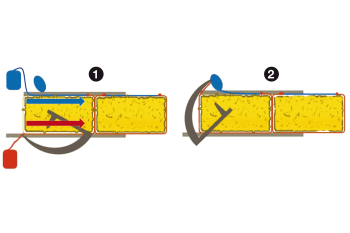

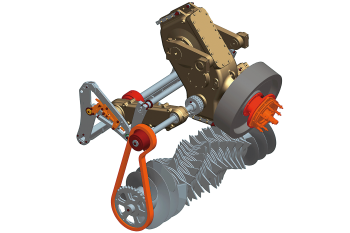

The D Series balers have been designed with simple, yet efficient features including Integral Rotor Technology and the Power Density System to produce rock-hard, square-edged bales in all crop conditions. Rasspe® double knotters are not only reliable, but allow you to increase bale density by 10% and the number of bales per hour by 15%. Dual hydraulic-driven fans keep our double knotters clean and our competitors envious. KUHN LSB balers feature the simplest drive system in the industry, fewest moving parts, heaviest standard flywheel and longest standard bale chamber to provide outstanding durability and performance. All KUHN LSB balers are ISOBUS compatible, therefore will not require a separate VT monitor for the baler. You can easily change settings such as bale density or knife activation from the comfort of your tractor seat.

YOUR BENEFITS

EQUIPMENT

ISOBUS Compatibility

All KUHN LSB balers are ISOBUS compatible. ISOBUS compatible tractors, therefore, will not require a separate monitor for the baler. Alternatively, the CCI 50 and CCI 1200 monitors can be used with tractors that are not ISOBUS compatible. Operator settings, such as bale density and knife activation, are accessed through the monitor. Operator warnings such as overload, twine routing and operator information, including flakes per bale and number of bales, are also provided.

Full Visibility

To provide optimal visibility and safety around the machine, the LSB can be equipped with a KUHN group camera system. There are two kits available, one kit is compatible with the CCI terminal, and the other one consists of a separate monitor and a camera.

Automatic Greasing

To reduce daily maintenance and to preserve your machine, the automatic central greasing system is fitted on most models. The automatic greasing system convers all the greasing points on the baler except for the drivelines and tandem axle.

Service Lights

The LSB D series balers are equipped with LED service lights on the needles and twine box for easy machine inspection.

Easy-Access Twine Boxes

The twine boxes swing out completely for easy access to the vital parts of the machine. Behind the full-access side doors, spools of twine can be stored. The LSB D Series balers have a twine capacity of 30 spools. The swine storage itself is sealed to keep twine rolls clean for consistent, reliable tying.

LED Work Lights

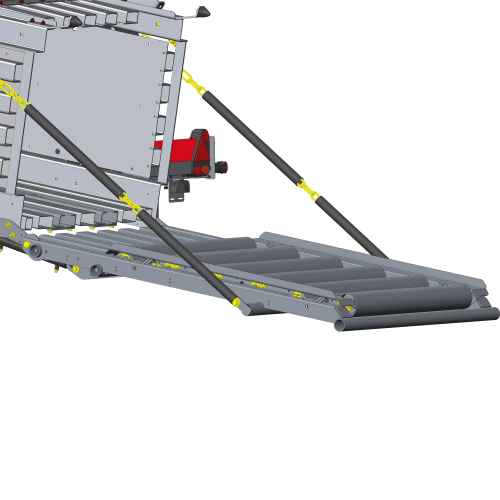

Optional LED work lights, on the pickup and the bale chute, allow you to have a clear view all night long.

Easy Flow Kit

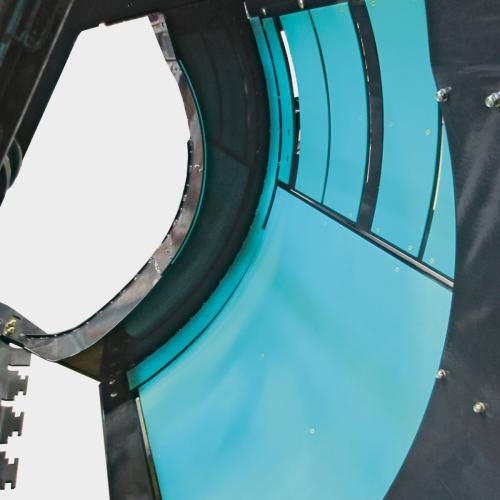

The easy flow kit is useful for silage conditions in wet/sticky material. The Teflon plates reduce friction for better crop flow.

Bale Drop Sensor

A bale drop sensor can be installed to alert the operator when the bale is dropping.

Moisture Sensor

All LSB balers can be equipped with a moisture sensor. Moisture information shows up in real time on the tractor monitor.

Integrated Bale Weighing System

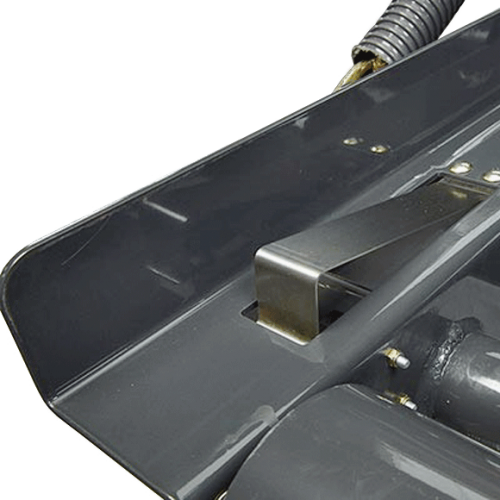

Use of the optional KUHN integrated bale weighing system provides on-the-go feedback about the bale weight, within 2% accuracy, plus direct insight in your crop yield.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com