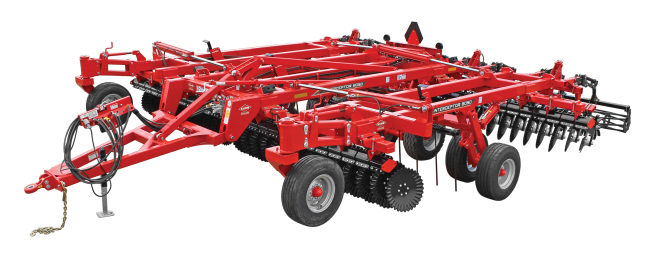

Aggressive, High-Speed Tillage

Your high-speed tillage solution for controlling troublesome, chemical resistant weeds, the Interceptor® 8050 was developed to provide growers with a more aggressive high-speed compact disc that leaves a level seedbed. Working Widths: 20’ – 30’

The KUHN Krause Interceptor® 8050 delivers high-speed tillage to control stubborn, chemical resistant weed growth, while sizing and evenly distributing tough residue into the worked soil profile. This action not only kills weeds and limits potential movement of wind driven residue, but also contributes to residue breakdown throughout the year and builds soil organic matter. Featuring independently mounted Excalibur® CT (Conservation Tillage) blades, adjustable, center-mounted tines, and the proven Star Wheel™ treaders with 24/7® finishing attachments, the Interceptor delivers a consistent, uniform field finish.

YOUR BENEFITS

Residue Incorporation

Excalibur® CT Blades

North American agronomy practices, like increased seeding rates, GMO hybrids and even varying soil moisture conditions must be reliably managed. The Interceptor’s depth-of-frame design provides ample distance for residue and soil flow between two parallel rows of 22-inch diameter, 32-flute Excalibur CT shallow concavity blades on 9” spacing. Each blade assembly is individually mounted on a compound angle with 6-bolt hubs and configured into a tandem design. The tandem blade configuration provides a consistent and uniform line of draft for high-speed implement tracking. This tandem design also contributes to a more uniform distribution of soil and residue verses competitive “offset disc” designs that can move residue and soil in a single direction.

Angle of Attack

Compound blade angles have been developed and incorporated to provide optimum soil penetration without applying excessive backside blade pressure to the soil. Ample fore-to-aft space exists between the front and rear rows of blades to allow high-speed soil and residue flow to settle before contacting the rear row of blades. Heavy soil and residue flow from the front blades of close-coupled competitive designs can potentially slow or stall the rotation of the rear blades, causing a “plug” or unevenness in the finished seedbed.

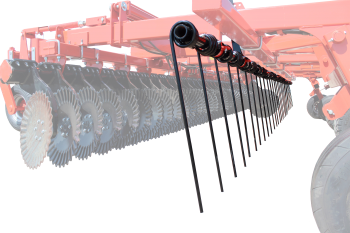

Center-Mounted HD Tines

Center-mounted HD tines incorporated into the frame area immediately behind the first rank of Excalibur® CT blades maintain full contact with the soil surface to initiate residue redistribution and soil leveling. The single row of 5/8” diameter x 30” length x 12” spaced tines feature adjustable angles to force residue and soil flow from the front blades downward, settling loose material before contacting the rear row of blades and finishing attachment.

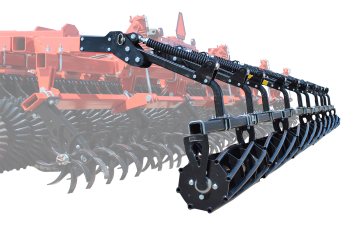

Quality Finishing

Star Wheel™ Treaders

Star Wheel™ treader gangs, mounted on 6-degree angles, level the seedbed and size clods, while mixing and anchoring residue into the loose soil. Constant-flow hydraulic down pressure on the Star Wheel treader allows the attachment to maintain even working pressure across a varying field surface, resulting in a consistent, uniform finish. Many competitive units depend upon their rear attachment to control machine operating depth and thereby transmit significant weight to their rear attachment, which can result in a tight, compressed seedbed.

24/7® Conditioning Reels

Available with flat blades for maximum clod sizing in hard soil conditions or round bars for increased soil firming in loamy soil conditions, this effective component completes a superior finish to any field.

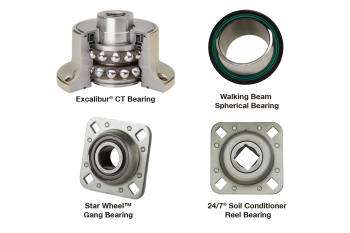

Maintenance-Free Bearings

Maintenance-Free Bearings

No daily grease maintenance required for the maintenance free bearings, incorporated into the Excalibur® CT gang assemblies, Star Wheel™ treaders and 24/7® conditioning reels. Spherical pivot bearing for each walking beam assembly requires no grease, along with rocker and wing hinge pivots.

24/7 Leveling Systems

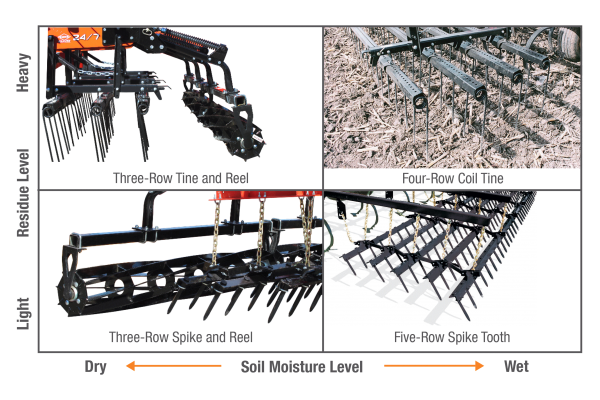

KUHN Krause offers a variety of harrows to meet your specific soil and residue requirements. These harrows are available for all sizes and provide time saving features to increase overall productivity.

SPECIFICATIONS

| Transport Width |

|---|

| Transport Height |

| Number of Blades |

| Working Width |

| Working Width |

| Blade Spacing |

| Weight |

| 8050-20 | 8050-25 | 8050-30 |

|---|---|---|

| 13’5″ (4.1 m) | 12’11” (3.9 m) | 16’5″ (5 m) |

| 11’5″ (3.5 m) | 13’5″ (4.1 m) | 14’1″ (4.3 m) |

| 54 | 66 | 78 |

| 20′ (6.1 m) | 25′ (7.6 m) | 30′ (9.1 m) |

| 19′ (5.8 m) | 24′ (7.3 m) | 29′ (8.8 m) |

| 9″ (22.9 cm) | 9″ (22.9 cm) | 9″ (22.9 cm) |

| 18,407 lb (8 349 kg) | 21,885 lb (9 927 kg) | 25,200 lb (11 431 kg) |

| Hitch Type |

|---|

| Tongue Type |

| Fore / Aft Leveling |

| Hydraulics |

| Wing Fold Cylinders |

| Lift Cylinders |

| Depth Control |

| Blades |

| Bearing Arms |

| Blade Hub Bearing |

| Mid-Mount Tines |

| Center Section Wheels |

| Wing Section Wheels |

| Wing Gauge Wheels |

| Finishing Attachments |

| 5635-20 | 5635-22 | 5635-24 | 5635-26 | 5635-28 | 5635-30 | 5635-32 | 5635-34 | 5635-36 | 5635-39 | 5635-42 | 5635-46 | 5635-50 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CAT III Cast Clevis, 1-½” Pin & Combination “C” Cast Clevis, 1-¼” Pin Hitch | CAT III Cast Clevis, 1-½” Pin & Combination “C” Cast Clevis, 1-¼” Pin Hitch | CAT III Cast Clevis, 1-½” Pin & Combination “C” Cast Clevis, 1-¼” Pin Hitch | CAT III Cast Clevis, 1-½” Pin & Combination “C” Cast Clevis, 1-¼” Pin Hitch | CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | Guardian Hitch™ (Cushion Tongue) with CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | Guardian Hitch™ (Cushion Tongue) with CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | Guardian Hitch™ (Cushion Tongue) with CAT IV Ball Style Cast Clevis Hitch, 2″ Pin | Guardian Hitch™ (Cushion Tongue) with CAT IV Ball Style Cast Clevis Hitch, 2″ Pin |

| Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Self-Leveling Hitch | Floating Hitch | Floating Hitch | Floating Hitch | Floating Hitch |

| All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders | All Cylinders and Hoses, Rephasing 10″ Lift Cylinders |

| Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop | Hydraulic Depth Control with Positive Stop |

| Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load | Spring Cushioned Shanks, 190 lb Point Load |

| 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style | 25″ Underframe Clearance, 1-3/4″ x 5/8″ Lower Shank Edge-On Style |

| R280/70R15″ Fl, 6-Bolt Hubs | R280/70R15″ Fl, 6-Bolt Hubs | R280/70R15″ Fl, 6-Bolt Hubs | R280/70R15″ Fl, 6-Bolt Hubs | R280/70R15″ Fl, 6-Bolt Hubs | R280/70R15″ Fl, 6-Bolt Hubs | R280/70R15″, 6-Bolt Hubs | R280/70R15″, 6-Bolt Hubs | (4) 340/60R16.5, 8-Bolt Hubs | (4) 340/60R16.5, 8-Bolt Hubs | (4) 340/60R16.5, 8-Bolt Hubs | (4) 340/60R16.5, 8-Bolt Hubs | (4) 340/60R16.5, 8-Bolt Hubs |

| (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (4) 280/70R15, 6-Bolt Hubs, (2) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (8) 280/70R15, 6-Bolt Hubs, (4) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (8) 280/70R15, 6-Bolt Hubs, (4) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (8) 280/70R15, 6-Bolt Hubs, (4) Front Castering Gauge Wheels 20.5″ x 8″ Load Range E | (8) 280/70R15, 6-Bolt Hubs, (4)Front Castering Gauge Wheels 20.5″ x 8″ Load Range E |

| 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® 3-Row Tine and Spiral HD Reel Combination with 11″ Diameter Spiral, Round Bar HD Reel Equipped with PEER® TILLXTREME™ Maintenance-Free Bearings |

| Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High Visibility LED Lighting |

| Fore / Aft Leveling |

|---|

| Tongue Type |

| Finishing Attachments |

| Finishing Attachments |

| Attachment |

| Attachment |

| Attachment |

| 8050-20 | 8050-25 | 8050-30 |

|---|---|---|

| Rear Hitch with Attachment Rear Hitch without Attachment None |

Rear Hitch with Attachment Rear Hitch without Attachment None |

Rear Hitch with Attachment Rear Hitch without Attachment None |

| Not Applicable | Not Applicable | Guardian Hitch™ (Cushion Tongue) with Mechanical Fore / Aft Adjustment, Level-Lift Tongue |

| Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant Flow 24/7® Heavy-Duty Flat Bar Reel Featuring PEER® TILLXTREME™ Maintenance-Free Bearings | Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant Flow 24/7® Heavy-Duty Flat Bar Reel Featuring PEER® TILLXTREME™ Maintenance-Free Bearings | Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant Flow 24/7® Heavy-Duty Flat Bar Reel Featuring PEER® TILLXTREME™ Maintenance-Free Bearings |

| HD 24/7® 3 Row Tine, 5/8″ x 30″ Tines, 12″ Spacing, Adjustable Tine Bar Angles, 14″ Spacing Between Tine Bar Rows | HD 24/7® 3 Row Tine, 5/8″ x 30″ Tines, 12″ Spacing, Adjustable Tine Bar Angles, 14″ Spacing Between Tine Bar Rows | HD 24/7® 3 Row Tine, 5/8″ x 30″ Tines, 12″ Spacing, Adjustable Tine Bar Angles, 14″ Spacing Between Tine Bar Rows |

| Dual HD 24/7® Round Rod Reel with Hydraulics | Dual HD 24/7® Round Rod Reel with Hydraulics | Dual HD 24/7® Round Rod Reel with Hydraulics |

| Dual HD 24/7® Flat Bar Reel with Hydraulics | Dual HD 24/7® Flat Bar Reel with Hydraulics | Dual HD 24/7® Flat Bar Reel with Hydraulics |

| Combination HD 24/7® Round Reel and Flat Bar Reel with Hydraulics | Combination HD 24/7® Round Reel and Flat Bar Reel with Hydraulics | Combination HD 24/7® Round Reel and Flat Bar Reel with Hydraulics |

| Recommended Operating Speed |

|---|

| Working Depth Range |

| Recommended Tractor Power |

| 8050-20 | 8050-25 | 8050-30 |

|---|---|---|

| 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) |

8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) |

8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) |

| 5″ (12.7 cm) | 5″ (12.7 cm) | 5″ (12.7 cm) |

| 15 – 20 ENG HP/ft (37 – 49 kW/m) | 15 – 20 ENG HP/ft (37 – 49 kW/m) | 15 – 20 ENG HP/ft (37 – 49 kW/m) |

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com