Customize Your Seedbed in One Pass

The HR 1030 Series power harrows carry KUHN’s solid reputation into a new generation with updated features and better performance including a heavy-duty drivetrain, redesigned rotor, more rotor speeds and adjustable leveling bar.

YOUR BENEFITS

EQUIPMENT

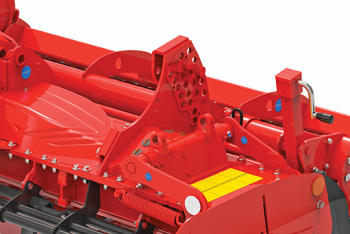

Track Eradicators

To ensure all of the soil is tilled properly, adjustable track eradicators are available as a field-installed option. Mounted to a separate support bracket ahead of the rotors, these small shanks follow the tractor wheels to break up any surface compaction that the tractor may have caused.

Side Deflector Shields

Standard side deflector shields help to keep the soil from forming ridges between passes. They are adjustable based the working depth and current level of blade wear by simply loosening the bolts. The bottom portion of the shields can be replaced when worn.

Stone Deflectors

Depending on the size and quantity of rocks encountered in the field, stone deflectors can be installed only on converging rotors, or between all rotors pointing in opposite directions. In deeper working applications, the deflectors can be removed to speed up work.

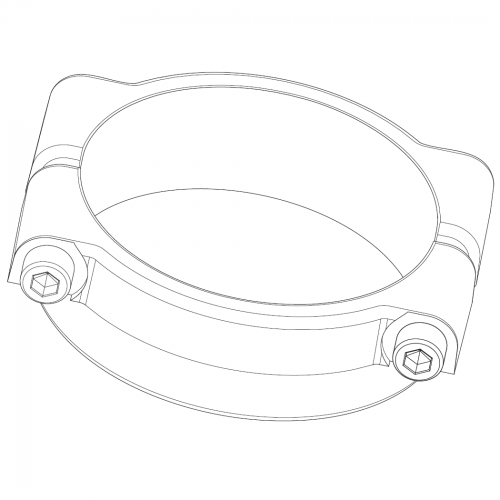

Anti-Wrap Bushings

Optional anti-wrap bushings fit into the groove in the blade holder. These are particularly useful in fields with significant amounts of string and/or wire to help reduce wear caused by the debris wrapping around the collars.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com