Proven hydraulic ProPush® design…Now with higher capacity!

The KUHN Knight HP 160 ProPush® hydraulic push-type spreader is designed to haul and spread solid materials from dairies and feedlots, including gutter manure, yard scrapings, bedding pack and feedlot manure. The HP 160 features a heaped capacity of 600 ft3 (17 m3).

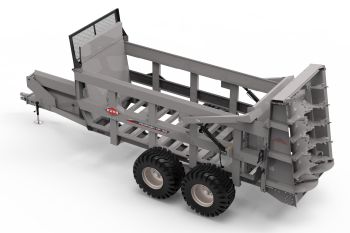

The new KUHN Knight HP 160 hydraulic push box spreader features the proven ProPush® design customers have come to love, just in a higher capacity, commercial duty package. The HP 160 with VertiSpread® vertical beaters is designed to haul and spread solid materials from dairies and feedlots, including gutter manure, yard scrapings, bedding pack and feedlot manure. The hydraulic push-type design means no apron chains, fewer moving parts and dependable service life.

The HP 160 joins the 2044 and 2054 ProPush hydraulic push box spreader family, but features new upgrades and a greater heaped capacity of 600 cubic feet. The all-steel welded frame on the HP 160 provides a solid foundation for the spreaders sides and floor. The solid weld-in tongue is cross-braced for strength and rigidity, while the updated pusher design has increased the clearance between the tractor and implement for greater maneuverability. VertiSpread vertical beaters equipped on the KUHN Knight HP 160 provide customers with a uniform 25-30 foot spread pattern with excellent material breakup. Poly floor and sides minimize friction and deliver exceptional machine cleanout. For precise monitoring and application tracking, an optional scale system is available.

YOUR BENEFITS

EQUIPMENT

Thrown Object Shield

The standard thrown object shield better protects the tractor and driver from flying debris. The grated design allows for easy viewing of the unloading process. Optional extensions provide greater protection by increasing both height and width.

Sequencing Valve

An optional sequencing valve is highly recommended and can be added to the HP 160 to protect against accidental pusher and gate collisions. It requires the gate to be all the way up, before it allows the pusher to be engaged. The orientation minimizes material buildup to maintain proper function of the sequencing valve.

Hydraulic Disc Brakes

Four wheel hydraulic disc brakes are optional. Hydraulic disc brakes are more reliable in manure applications than drum or air brakes since they are easier to keep free of foreign material and have fewer moving parts. The hydraulic brakes are activated using the hydraulic braking port provided on the tractor.

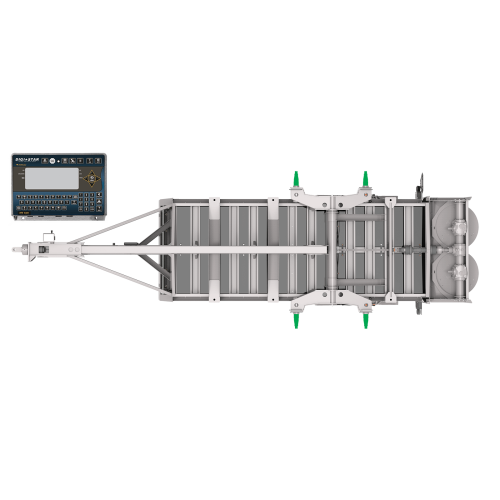

Scale System

An optional 5-point scale system allows the operator to accurately determine how much material is in the spreader, as well as how much is being applied to the field.

Units equipped with electronic scales can also be fitted with an optional scale indicator, the TopCon/Digi-Star NT 560. This allows an operator to better manage the material they are spreading, by understanding the rate at which the material is leaving the spreader. This also allows the operator to accurately apply the desirable tons/acre.

Hitch Options

The HP 160 comes with the choice of a swivel clevis or spade-style hitch with or without scales. Both are easily replaceable or reversed for greater service capability.

Electric Speed Flow Control

An option for tractors that do not have flow control capabilities, the electric flow control allows the operator to easily adjust the apron speed from inside the cab to suit specific materials or speeds. This provides increased flexibility when spreading a variety of materials.

Manual Flow Control

For tractors that don’t have flow control capabilities, the manual flow control allows the operator to easily adjust the apron speed to suit specific materials or speeds. This increases flexibility when spreading a variety of materials.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com