Modern Style, Meets Great Performance

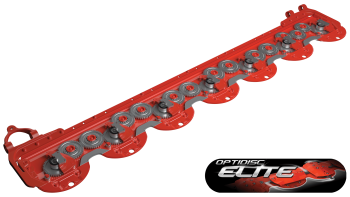

KUHN GMD 25 F Series front mounted mowers, with working widths ranging from 10’2” to 11’6 can be used on their own, or as part of a triple-mower combination allowing you to cut up to 32’6” in one pass.

As the first to market and industry leader, KUHN knows disc mowers. The GMD 51 TL Series trailed disc mowers have many of the same great features you have come to know and love. These trailed mowers offer high working rates, simple adjustments and low maintenance for dependable grass and forage harvesting. They provide easy tractor attachments, as well as improved contour following, compared to the fully mounted models. The trailed design also lowers the tractors ballast requirement, allowing use with smaller tractors while maintaining excellent stability in both work and transport.

YOUR BENEFITS

EQUIPMENT

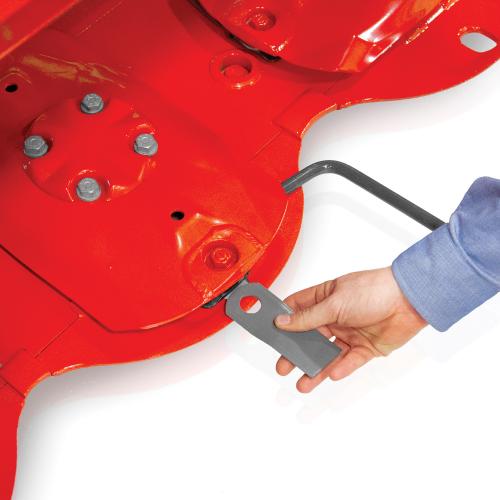

Fast-Fit

An optional Fast-Fit kit can be added. The Fast-Fit quick-release knife system allows quick changing of knives with the use of a simple tool, yet still provides the optimum cut quality and knife life seen with the standard system. With Fast-Fit, you can achieve up to 50% time savings.

Plastic Rock Guards

A HDPE (high-density polyethylene) rock guard can be mounted on the underside of the front hood for added protection in rocky conditions.

High-Lift Skids Shoes

For customers requiring a higher cut height for certain crops or when cutting in rocky conditions. The skids are adjustable for cutting between 2.1” – 6”.

CV Secondary PTO Shaft

For flexibility to steer around obstacles in the field with the mowers’ hydraulic swing cylinder or to mow directly behind the tractor without PTO chatter, a secondary PTO shaft equipped with a constant velocity joint can be factory ordered or field installed.

1000 RPM Drive

An optional 1000 RPM PTO offers flexibility for the customer to run the mower with a larger tractor and provides dependable operation in varied conditions.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com