A Well Rounded and Versatile Disc Mower

The KUHN GMD 355 mounted disc mower is great for operators who are looking for versatility, high cutting performance and durability.

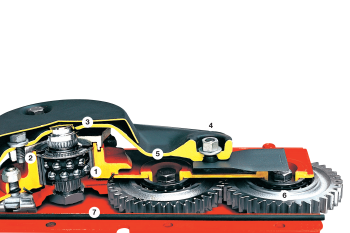

The KUHN GMD 355 disc mower provides operators with increased durability, enhanced features and a cleaner look for years of low maintenance hay production. Equipped with KUHN’s 100 Series cutterbar, the GMD 355 has proven cutting performance in the field. It has also been reinforced with heavy-duty outer bearing stations to support both ends of the cutterbar. These supports greatly improve the durability of the cutterbar, especially when it is used in difficult conditions. The swath wheel improves crop flow by providing positive engagement of the crop. The spring suspension of the cutting unit has adaptive flotation for the cutterbar to float over uneven terrain. The mechanical breakaway protects the mower along fence lines and field edges in case an obstacle is struck.

YOUR BENEFITS

EQUIPMENT

Cutterbar Lifting Skids

These lifters are available for mowing conditions which require elevated cutting heights. Up to 3.5” (90 mm) are possible. They will also prove useful in wet and sticky mowing conditions.

1000 RPM Drive

An optional 1000 RPM PTO offers flexibility for the customer to run the mower with a larger tractor and provides dependable operation in varied conditions.

Parking Stand

An optional parking stand can be ordered to store the mower in the vertical position to save space in the shed.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com