Cutting-Edge Mower Conditioners

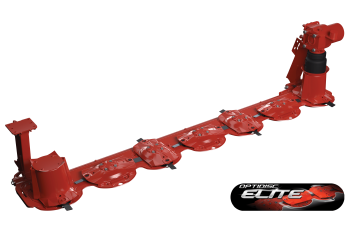

KUHN FC 61 TL Series side-pull are reliable mower conditioners with advanced features yet have the operational simplicity you want and the performance you demand for the maximum return on investment. Working widths range from 9’ 2” to 11’6”.

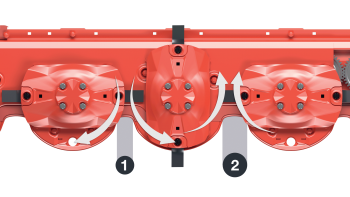

KUHN FC 61 TL Series mower conditioners offer fast, clean mowing of heavy grasses and delicate forage crops alike, combined with quick drydown from effective conditioning. With a broad range of windrow width settings, along with finger, rubber roller and steel roller conditioning options, KUHN mower conditioners offer unmatched adaptability to different harvest practices and field conditions.

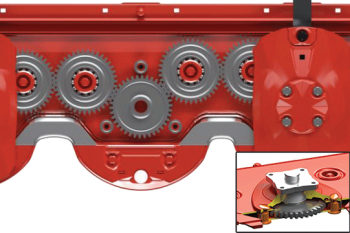

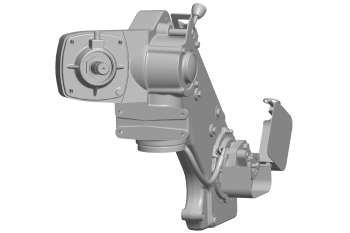

The rugged Gyrodine® swivel hitch makes sharp turns and square corners simple. The lubed-for-life Optidisc® Elite cutterbar with Fast-Fit® blades provides unmatched simplicity and fast maintenance. Outstanding suspension provides fast, precise flotation to adapt to various crop and field conditions. These advanced features, combined with simple adjustments and low maintenance, make KUHN mower conditioners the premier machines on the market.

YOUR BENEFITS

EQUIPMENT

CV Secondary PTO Shaft

For flexibility to steer around obstacles in the field with the mowers’ hydraulic swing cylinder, or to mow directly behind the tractor without PTO chatter, a secondary PTO shaft equipped with a constant velocity joint can be factory ordered or field installed. This option is highly recommended for operation with tractors that have narrow or typical row crop spaced tires.

Plastic Rock Guards

A rock guard can be mounted on the underside of the front hood for added protection in rocky conditions.

High-Lift Skids Shoes

For customers requiring a higher cut for certain crops or when cutting in rocky conditions. The high skids replace the liners and increase cutting height to 1.8” – 3.4” (45 – 85 mm) depending on header angle.

Crop Lifters

Recommended only for sorghum or other hard feeding crops.

1000 RPM Drive

An optional 1000 rpm PTO offers flexibility for the customer to run the mower with a larger tractor and provides dependable operation in varied conditions.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com