Designed for TRUE Vertical Tillage

With 8 models ranging in working widths, between 11’-50’, the Excelerator® 8005 provides exceptional residue cutting, soil and residue mixing and seedbed preparation in one pass, utilizing an exclusive 4-step process.

The KUHN Krause Excelerator® vertical tillage system provides exceptional residue cutting, soil and residue mixing and seed bed preparation in one pass, utilizing an exclusive 4-step process. True vertical tillage delivers residue cutting and soil mixing without soil shearing or smearing in the critical zone for seed placement and young seedling root development. With its unique Excalibur® VT (vertical tillage) blades, designed to meet the challenges of cutting tough GMO residue, you can be confident that the residue management achieved during fall operation will allow maximum residue decomposition over winter. In addition, spring operation will accomplish your goals of superior seedbed preparation in high residue situations.

The KUHN Krause CCX 9000 cover crop seeder, for use on Excelerator models (11’-34’), provides you with the ability to establish a cover crop while performing vertical tillage – saving you time and money!

YOUR BENEFITS

EQUIPMENT

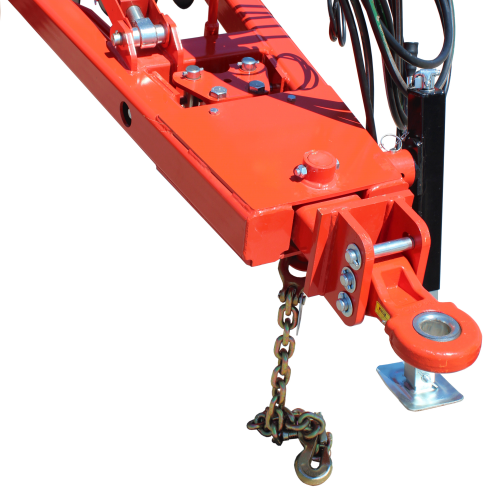

Guardian Hitch™

This exclusive option guards against stress on the tractor drawbar and implement frame. Lateral drawbar forces are transferred through the hitch pivot where shock load from steering input is dampened by urethane blocks. Choose from the articulating ball Cat III, IV or V double-bolt, cast hitch, depending on model.

Single-Point Depth Control

Blade depth is conveniently controlled with crank adjustable depth stop located at the front of the machine. View working depth on the easy-to-read scale.

Star Wheel™ Hydraulics

Live hydraulic action keeps treaders in contact with soil contours maintaining uniform operational pressure across the width of the machine. This allows for superior soil leveling and residue mixing.

Hydraulic Wing Down Pressure

The Excelerator® features standard constant-flow hydraulic down pressure. This feature can add additional downforce to each wing via the wing fold cylinders. This feature stabilizes each wing section during high-speed operation.

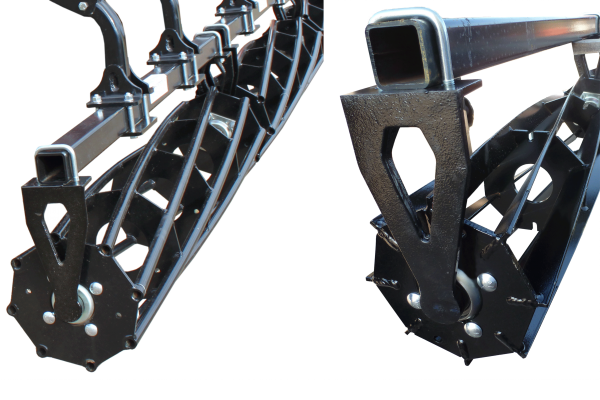

Walking Beams

Standard heavy-duty walking beams on the center section feature heavy-duty wheel hubs, with “slip-in” spindles for easy servicing. Walking beam assemblies feature spherical pivot bearings requiring no daily grease maintenance. Walking beams on each wing have 6-bolt hubs, with bolt-in spindles as standard equipment.

Maintenance-Free Bearings

No daily grease maintenance required for the new PEER® TILLXTREME™ maintenance-free bearings, now incorporated into the Excalibur® VT gang assemblies, Star Wheel™ treaders and 24/7® conditioning reels. Spherical pivot bearing for each walking beam assembly requires no grease, along with rocker and wing hinge pivots.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com