Unequaled Spreading Precision

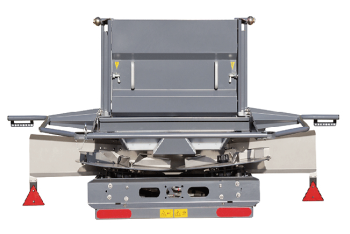

The Axent™ 100.1 trailed fertilizer spreader is a large acreage dry fertilizer and lime applicator providing operators with high precision rate control, wide working widths, high capacity and lime capability, Opti-Point and Vari-Spread and ISOBUS compatibility.

The KUHN Axent™ 100.1 trailed fertilizer spreader is the ultimate large-acreage dry fertilizer and lime applicator. Innovative technologies including EMC rate control, Opti-Point, and Vari-Spread create an industry-unique combination of high capacity and high precision that saves fertilizer and offers outstanding return on investment. Wide working widths reduce the number of passes required in each field, lowering fuel consumption and preserving soil structure. ISOBUS compatibility makes all of this capability easy to use and integrate into your operation.

YOUR BENEFITS

EQUIPMENT

ISOBUS Compatible

Operators have the ability to “plug and play” with existing ISOBUS virtual terminals for ultimate simplicity. The Axent™ is variable rate ready without needing an additional rate controller. The KUHN CCI 50 and the CCI 1200 ISOBUS terminals are available on the Axent™ fertilizer spreader.

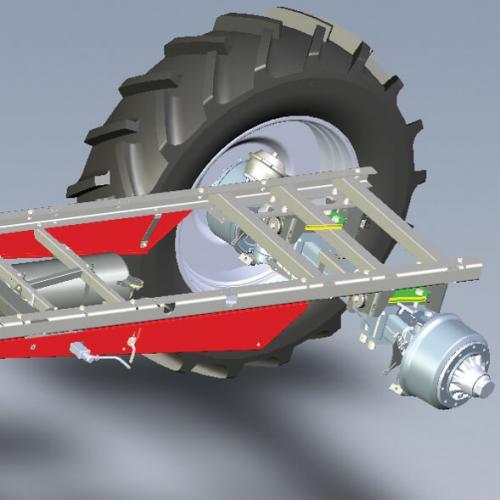

Steerable Axle

The Axent can be ordered from the factory with a steerable axle to more closely follow the tractor’s tires and limit areas compacted or run over. The system uses a small gyroscope mounted on the tractor and is easily moved from tractor to tractor. The steering angle ranges between 11 and 17 degrees based on the tire size selected.

Hydraulic Brakes

Hydraulic brakes can be ordered if desired.

Tire Options

Machines come standard with 650/65 R42 floater tires. However, narrower tires can be ordered as an option for in-row application.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com