Designed for Today’s Tough Residue

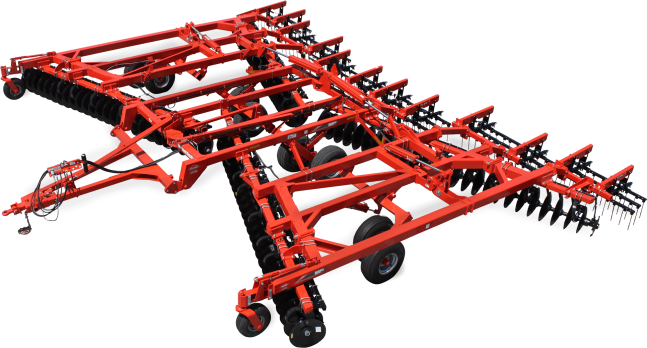

Designed to provide primary tillage operation where maximum soil penetration and residue mixing is required. Working widths range from 19’10” to 37’3”.

The KUHN Krause Class III 8320 tandem disc harrows provide primary tillage operation utilizing greater gang angles and a weight increase over Class II all purpose disc harrows. Heavier main and wing frame components combined with improved weld joint construction increase strength and reliability. New spring adjustable scraper assemblies provide aggressive and positive cleaning action in a variety of field conditions.

Residue Razor™ disc blades, aggressive gang angles and a significant weight increase over all-purpose tandem disc harrows means the 8320 delivers better residue cutting and mixing. With a wide or narrow spacing, producers can configure the 8320 tandem disc harrow to match their residue and soil conditions for optimum performance. Choose a 24/7® leveling system for a reliable seedbed finish.

YOUR BENEFITS

The Strength is in the Gang

Castering Gauge Wheels

To help pivot with the disc harrow on contours, instead of creating a furrow, the castering gauge wheels are standard on the Quad-Fold™ models and optional on others. The wrenchless adjustment makes setting easier than ever. Unlike rigid gauge wheels, castering wheels pivot on contours, instead of sliding in loose soil.

Residue Razor™ Disc Blades

All KUHN Krause tandem disc harrows are available with Residue Razor disc blades made from Ingersoll’s PURE™ steel optimizing strength to withstand stress, fractures, and to provide flexibility in rock conditions. Residue Razor discs have an exceptionally sharp edge, five times sharper than conventional blades.

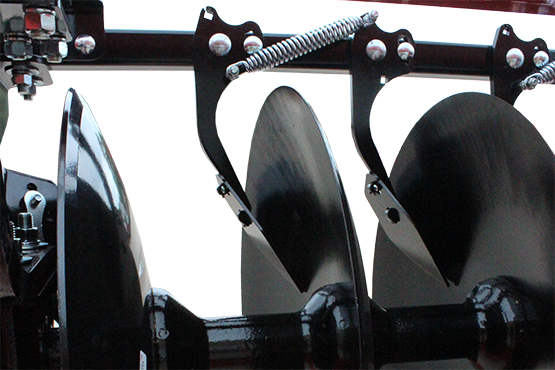

Spring Adjust Scrapers

The 5-inch scraper is easily adjusted by simply loosening a single bolt, adjusting for scraper gap if needed and locking in place by tightening the bolt. The scraper spring provides the tension to move the scraper to the specified location against the face of the disc blade.

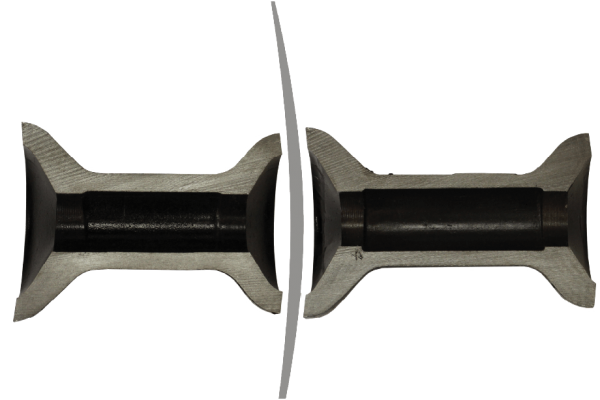

Spools

KUHN Krause heavy-cast spools multiply the strength of the disc gang. Spools are line-bored for an exact fit on the tie rod and precision faced to perfectly match the blade surface. A larger bell on the concave end and a smaller bell on the convex end provide an overlap fit against the blades, supporting the blade more positively without creating a stress line.

Rock-Flex Bearing Arm

Rock-flex bearing arms provide protection from rocky or hard soil conditions and feature PEER® TILLXTREME™ maintenance-free bearings. The bearing arm scraper has adjustability to clean the concave side of each disc blade located at the Rock-Flex bearing arms limiting soil and residue buildup in the bearing hanger area.

Remote Depth Control

Single-Point Remote Depth Control

Single-point remote depth control, conveniently located at the front of the disc, makes it easy to fine-tune depth adjustments. Return to the same depth after each pass or change depth from field to field in a matter of seconds. The sight gauge makes depth setting more convenient.

Heavy-Duty Walking Beams

Standard on all 8320 disc harrows, heavy-duty walking beams allow for consistent working depth on rough ground and more stable road transport. Walking beams have slip-in spindles and heavy-duty hubs.

Wide or Narrow Spacing

Fore-Aft Leveling

Optional hydraulic leveling allows for field-to-field, front-to-rear leveling adjustments without leaving the cab.

24/7® Leveling Systems

Increase yield potential through better seedbed condition and increase productivity with non-stop farming. KUHN Krause disc harrows can be equipped with the following 24/7® leveling systems:

- 24/7® 3-Row Coil Tine Harrow: Featuring a parallel link leveling system for superior residue flow and even distribution, the coil tine harrow offers an increase in yield potential and improved residue management even in high residue conditions. With 16” long tines, 7/16” diameter, the 24/7 Coil Tine Harrow ensures smoother residue distribution and better chemical incorporation.

- 3-Bar Spike Harrow: For excellent clod sizing in low to moderate residue conditions, the 3-bar spike harrow is an efficient way to create a level seedbed. Rugged ¾” x 10” square spikes provide long-lasting leveling.

- 24/7® Soil Conditioning Reel: For maximum clod sizing, leveling and soil firming the 24/7 soil conditioning reel is your choice. Choose the round, spiral rods for loamy soils or flat, spiral blades for high clay soils. A float setting widens the tillage/weather window when operating in wet soil conditions.

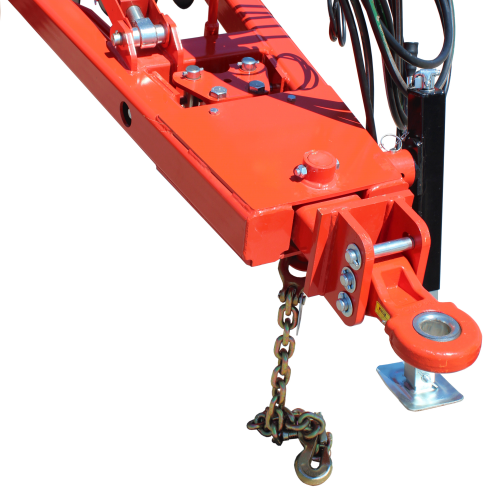

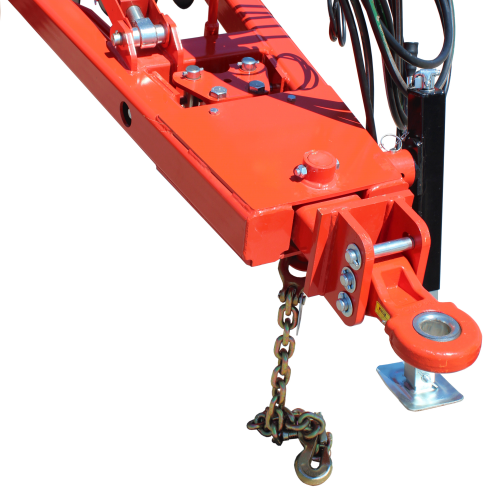

Rear Hitch

Wide or Narrow Spacing

The optional rear hitch features an extendable tongue allowing one person to easily connect towed implements.

24/7® Leveling Systems

Increase yield potential through better seedbed condition and increase productivity with non-stop farming. KUHN Krause disc harrows can be equipped with the following 24/7® leveling systems:

- 24/7® 3-Row Coil Tine Harrow: Featuring a parallel link leveling system for superior residue flow and even distribution, the coil tine harrow offers an increase in yield potential and improved residue management even in high residue conditions. With 16” long tines, 7/16” diameter, the 24/7 Coil Tine Harrow ensures smoother residue distribution and better chemical incorporation.

- 3-Bar Spike Harrow: For excellent clod sizing in low to moderate residue conditions, the 3-bar spike harrow is an efficient way to create a level seedbed. Rugged ¾” x 10” square spikes provide long-lasting leveling.

- 24/7® Soil Conditioning Reel: For maximum clod sizing, leveling and soil firming the 24/7 soil conditioning reel is your choice. Choose the round, spiral rods for loamy soils or flat, spiral blades for high clay soils. A float setting widens the tillage/weather window when operating in wet soil conditions.

Rear Hitch

Guardian Hitch™

Standard on all Quad-Fold models, the Guardian Hitch guards against stress on the tractor drawbar and implement frame. Lateral drawbar forces are transferred through the hitch pivot where shock load from steering input is dampened by urethane blocks.

24/7® Leveling Systems

Increase yield potential through better seedbed condition and increase productivity with non-stop farming. KUHN Krause disc harrows can be equipped with the following 24/7® leveling systems:

- 24/7® 3-Row Coil Tine Harrow: Featuring a parallel link leveling system for superior residue flow and even distribution, the coil tine harrow offers an increase in yield potential and improved residue management even in high residue conditions. With 16” long tines, 7/16” diameter, the 24/7 Coil Tine Harrow ensures smoother residue distribution and better chemical incorporation.

- 3-Bar Spike Harrow: For excellent clod sizing in low to moderate residue conditions, the 3-bar spike harrow is an efficient way to create a level seedbed. Rugged ¾” x 10” square spikes provide long-lasting leveling.

- 24/7® Soil Conditioning Reel: For maximum clod sizing, leveling and soil firming the 24/7 soil conditioning reel is your choice. Choose the round, spiral rods for loamy soils or flat, spiral blades for high clay soils. A float setting widens the tillage/weather window when operating in wet soil conditions.

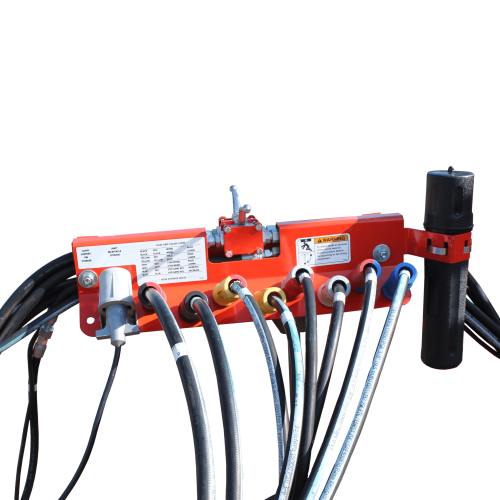

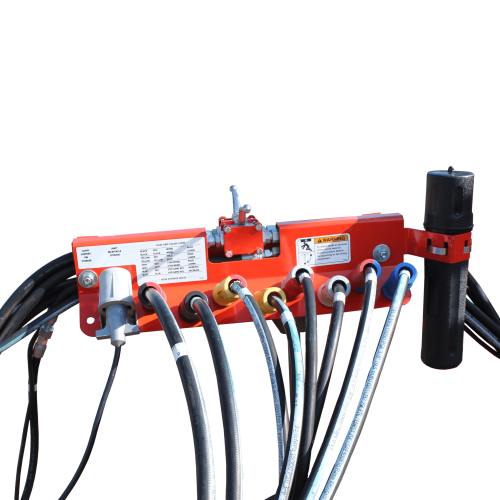

Tractor Interface Center

Tractor Interface Center

The tractor interface center prevents hydraulic hoses from binding in turns and adds operator convenience. Includes hose routing chart, color coded hose grips, storage for light hookup and owner’s manual.

24/7® Leveling Systems

Increase yield potential through better seedbed condition and increase productivity with non-stop farming. KUHN Krause disc harrows can be equipped with the following 24/7® leveling systems:

- 24/7® 3-Row Coil Tine Harrow: Featuring a parallel link leveling system for superior residue flow and even distribution, the coil tine harrow offers an increase in yield potential and improved residue management even in high residue conditions. With 16” long tines, 7/16” diameter, the 24/7 Coil Tine Harrow ensures smoother residue distribution and better chemical incorporation.

- 3-Bar Spike Harrow: For excellent clod sizing in low to moderate residue conditions, the 3-bar spike harrow is an efficient way to create a level seedbed. Rugged ¾” x 10” square spikes provide long-lasting leveling.

- 24/7® Soil Conditioning Reel: For maximum clod sizing, leveling and soil firming the 24/7 soil conditioning reel is your choice. Choose the round, spiral rods for loamy soils or flat, spiral blades for high clay soils. A float setting widens the tillage/weather window when operating in wet soil conditions.

EQUIPMENT

Castering Wing Gauge Wheels

To help pivot with the disc harrow on contours, instead of creating a furrow, the castering gauge wheels are standard on the Quad-Fold™ models and optional on others. The wrenchless adjustment makes setting easier than ever. Unlike rigid gauge wheels, castering wheels pivot on contours, instead of sliding in loose soil.

Single-Point Remote Depth Control

Single-point remote depth control, conveniently located at the front of the disc, makes it easy to fine-tune depth adjustments. Return to the same depth after each pass or change depth from field to field in a matter of seconds. The sight gauge makes depth setting more convenient.

Tractor Interface Center

Optional hydraulic leveling allows for field-to-field, front-to-rear leveling adjustments without leaving the cab.

Rear Hitch

The optional rear hitch features an extendable tongue allowing one person to easily connect towed implements.

Rear Hitch

Standard on all Quad-Fold models, the Guardian Hitch guards against stress on the tractor drawbar and implement frame. Lateral drawbar forces are transferred through the hitch pivot where shock load from steering input is dampened by urethane blocks.

Rear Hitch

The tractor interface center prevents hydraulic hoses from binding in turns and adds operator convenience. Includes hose routing chart, color coded hose grips, storage for light hookup and owner’s manual.

SPECIFICATIONS

| Transport Width |

|---|

| Transport Height |

| Frame Type |

| Number of Disc Blades |

| Number of Bearing Arms |

| Working Width |

| Disc Blade Spacing |

| Disc Gang Angle |

| Weight |

| 8320-19N | 8320-19W | 8320-22N | 8320-22W | 8320-25N | 8320-25W | 8320-28N | 8320-28W | 8320-31N | 8320-31W | 8320-34N | 8320-34W | 8320-37NQF | 8320-37WQF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12’2″ (3.7 m) | 12’2″ (3.7 m) | 12’2″ (3.7 m) | 12’2″ (3.7 m) | 14’1″ (4.3 m) | 14’1″ (4.3 m) | 17′ (5.2 m) | 17′ (5.2 m) | 17′ (5.2 m) | 17′ (5.2 m) | 17′ (5.2 m) | 17′ (5.2 m) | 17’7″ (5.3 m) | 17’7″ (5.3 m) |

| 10’9″ (3.3 m) | 10’9″ (3.3 m) | 12’2″ (3.7 m) | 12’2″ (3.7 m) | 11’11” (3.6 m) | 11’11” (3.6 m) | 13′ (4 m) | 13′ (4 m) | 13’10” (4.2 m) | 13’10” (4.2 m) | 14’8″ (4.5 m) | 14’8″ (4.5 m) | 13’5″ (4.1 m) | 13’5″ (4.1 m) |

| 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 3-Section | 5-Section Quad-Fold | 5-Section Quad-Fold |

| 52 | 50 | 60 | 58 | 66 | 62 | 74 | 70 | 82 | 78 | 90 | 86 | 100 | 94 |

| 16 | 16 | 18 | 18 | 22 | 20 | 22 | 22 | 26 | 24 | 26 | 26 | 30 | 30 |

| 19’10” (6 m) | 19’10” (6 m) | 22’11” (7 m) | 22’11” (7 m) | 24’7″ (7.5 m) | 24’7″ (7.5 m) | 27’9″ (8.5 m) | 27’9″ (8.5 m) | 30’11” (9.4 m) | 30’11” (9.4 m) | 34’1″ (10.4 m) | 34’1″ (10.4 m) | 37’3″ (11.4 m) | 37’3″ (11.4 m) |

| 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) | 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) | 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) | 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) | 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) | 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) | 9″ (22.9 cm) Front 10″ (25.4 cm) Rear | 10″ Front, 10″ Rear (25.4 cm) |

| 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear | 22 Degrees Front, 19 Degrees Rear |

| 14,251 lb (6 4674 kg) | 14,119 lb (6 404 kg) | 15,218 lb (6 904 kg) | 15,093 lb (6 846 kg) | 16,321 lb (7 362 kg) | 16,033 lb (7 272 kg) | 20,035 lb (9 088 kg) | 19,787 lb (8 975 kg) | 20,747 lb (9 411 kg) | 20,283 lb (9 200 kg) | 21,547 lb (9 774 kg) | 21,294 lb (9 659 kg) | 27,989 lb (12 696 kg) | 27,719 lb (12 573 kg) |

| Hitch Type |

|---|

| Tongue Type |

| Leveling |

| Hydraulics |

| Depth Control |

| Tractor Interface Center |

| Disc Gangs |

| Disc Blades |

| Taper Blades |

| Disc Scrapers |

| Center Section Tires |

| Wing Frame Tires |

| Wing Gauge Wheels |

| Transport Locks and Safety |

| 8320-19N | 8320-19W | 8320-22N | 8320-22W | 8320-25N | 8320-25W | 8320-28N | 8320-28W | 8320-31N | 8320-31W | 8320-34N | 8320-34W | 8320-37NQF | 8320-37WQF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Articulating Ball CAT III, 1-½” Pin | Articulating Ball CAT III, 1-½” Pin | Articulating Ball CAT III, 1-½” Pin | Articulating Ball CAT III, 1-½” Pin | Articulating Ball CAT III, 1-½” Pin | Articulating Ball CAT III, 1-½” Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin | Articulating Ball CAT IV, 2″ Pin |

| Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Level-Lift Tongue | Guardian Hitch™ (Cushioned Tongue) | Guardian Hitch™ (Cushioned Tongue) |

| Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable | Hydraulic Fore / Aft Adjustable |

| Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips |

| Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control | Single-Point, Crank Style Hydraulic Depth Control |

| Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves | Storage for Hydraulic Hose Ends, Electrical Connection and Transport Hydraulic Lock Valves |

| 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 7″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Tie Rod Wrench |

| 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge | 26″ x ¼” Residue Razor™ Solid Edge |

| Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler | Front 26″ – 24″, Rear 26″ – 24″ – 22″ – 20″ Bolt-On Furrow Filler |

| 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations | 5″ Spring Adjustable Scrapers with Adjustable Blade Scrapers at Bearing Arm Locations |

| (4) 280/70R15, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (4) 280/70R15, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (4) 280/7015, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (4) 280/70R15, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (4) 280/70R15, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (4) 280/70R15, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs | (4) 340/60R16.5, Walking Beams with Slip-In Spindles, 8-Bolt Heavy-Duty Hubs |

| (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 280/70R15 per Wing, Walking Beams with Slip-In Spindles, 6-Bolt Heavy-Duty Hubs | (2) 340/60R16.5 per Wing, Walking Beams with Slip-In Spindles, 8- Bolt Heavy-Duty Hubs | (2) 340/60R16.5 per Wing, Walking Beams with Slip-In Spindles, 8- Bolt Heavy-Duty Hubs |

| Not Available | Not Available | Not Available | Not Available | Not Available | Not Available | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E |

| Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit | Hydraulic Valve Wing-Fold and Transport Locks, Slow Moving Vehicle Sign, High Visibility LED Lighting kit |

| Wing Gauge Wheels |

|---|

| Wing Gauge Wheels |

| Leveling |

| Disc Blades |

| Taper Blades |

| Rear Hitch |

| Finishing Attachments |

| Finishing Attachments |

| Finishing Attachments |

| 8320-19N | 8320-19W | 8320-22N | 8320-22W | 8320-25N | 8320-25W | 8320-28N | 8320-28W | 8320-31N | 8320-31W | 8320-34N | 8320-34W | 8320-37NQF | 8320-37WQF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E | (2) 20.5 x 8 Load Range E |

| (2) 20.5 x 8 Kevlar | None | (2) 20.5 x 8 Kevlar | None | (2) 20.5 x 8 Kevlar | None | None | None | None | None | None | None | None | None |

| Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable | Mechanical Fore / Aft Adjustable |

| 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge | 24″ x ¼” Residue Razor™ Solid Edge |

| Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler | Front 24″ – 22″, Rear 24″ – 22″ – 20″ – 18″ Bolt-On Furrow Filler |

| Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) | Rear Hitch (Not for Use with Finishing Attachments) |

| 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow | 24/7® 3-Row 16″ Tine Harrow |

| 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow | 3-Bar Spike Harrow |

| 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) | 24/7® Soil Conditioning HD Reel with Float Position (Flat or Round Spirals) |

| Recommended Operating Speed |

|---|

| Working Depth Range |

| Recommended Tractor Power |

| 8320-19N | 8320-19W | 8320-22N | 8320-22W | 8320-25N | 8320-25W | 8320-28N | 8320-28W | 8320-31N | 8320-31W | 8320-34N | 8320-34W | 8320-37NQF | 8320-37WQF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) | 4 – 6 mph (6 – 10 km/h) |

| 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) | 3″ – 8″ (7.5 – 20.3 cm) |

| 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) | 9 – 12 ENG HP/ft (23 – 29 kW/m) |

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com