Residue Management, Superior Leveling

Designed for seedbed finishing, KUHN Krause 8100 disc harrows deliver excellent residue cutting and seedbed preparation. Working widths range from 12’3” – 18’1”.

The KUHN Krause Class I – Seedbed Finishing 8100 tandem disc harrows offer the quality and reliability you need for proper placement of your high value seeds. These machines deliver excellent residue cutting and seedbed preparation. Proper seed placement is critical to maximize yield potential. These discs provide a good weight-to-blade ratio to ensure consistent operation in a variety of soil conditions.

The 8100 disc harrow offers tillage versatility to the owners of 60 to 145 horsepower tractors. With features like rock-flex bearing arms, 22” Residue Razor™ disc blades with narrow or wide spacing, adjustable gang angle, dual wheels and a built-in rear hitch, the 8100 disc harrow allows operators to perform seedbed preparation and residue management with a variety of options.

YOUR BENEFITS

The Strength is in the Gang

Gang Design and Residue Razor™ Disc Blades

8100 tandem disc harrow gangs feature 22” diameter Residue Razor™ blades, mounted on Rock-Flex bearing arms, with SuperSeal regreasable bearings. The front gang angle is adjustable from 15 to 21 degrees, and the rear gang angle is adjustable from 12 to 18 degrees. Adjusting the gang angles gives this machine unmatched performance for residue sizing, soil mixing, herbicide incorporation and field finish. Rear gangs feature tapered blades to provide a level pass-to-pass finish. Bolt-on extension spool and furrow filler blades are standard equipment on 8100 discs, so inadvertently hitting an obstacle doesn’t damage the entire gang.

All KUHN Krause tandem disc harrows feature Residue Razor disc blades that are engineered with a unique Boron steel optimizing strength to withstand stress, fractures, and to provide flexibility in rock conditions. Residue Razor discs have an exceptionally sharp edge, five times sharper than conventional blades.

Rigid Scrapers

KUHN Krause rigid scrapers are heat treated and hot formed from the same high carbon steel we use in our disc blades. The result is an extremely strong and efficient scraper that resists wear. You can adjust each scraper individually or move the entire gang of scrapers at the same time. 3 ½” wide scrapers are standard equipment. Double scrapers at bearing arms are optional.

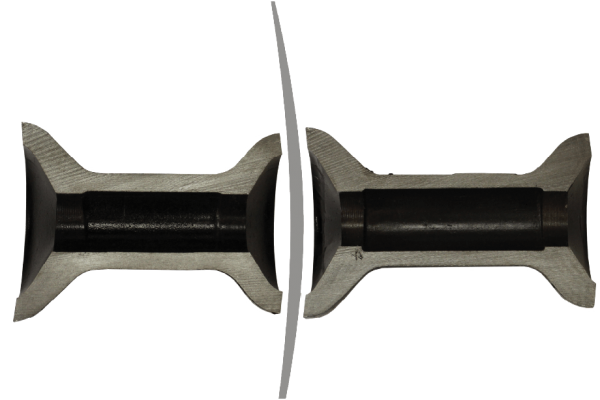

Spools

KUHN Krause heavy-cast spools multiply the strength of the disc gang. Spools are line-bored for an exact fit on the tie rod and precision faced to perfectly match the blade surface. A larger bell on the concave end and a smaller bell on the convex end provide an overlap fit against the blades, supporting the blade more positively without creating a stress line.

Depth Control

Single Location Remote Depth Control

Heavy-duty, rigid frame with simple, adjustable stop-collar depth control.

Wide or Narrow Spacing

Wide or Narrow Spacing

Choose wide or narrow spacing to better match the needs of your operation.

- Wide Spacing: Wide, 9 1/8”, spacing offers more aggressive residue mixing and leaves a course finish to resist wind erosion and aid in the drying of soil.

- Narrow Spacing: Narrow, 8”, spacing offers more aggressive residue cutting and leaves a smooth seedbed, ready to plant.

EQUIPMENT

Combination Hitch

The combination hitch offers convenience for different styles of tractor drawbars.

Rear Hitch

The rear hitch is standard on all 8100 disc harrows.

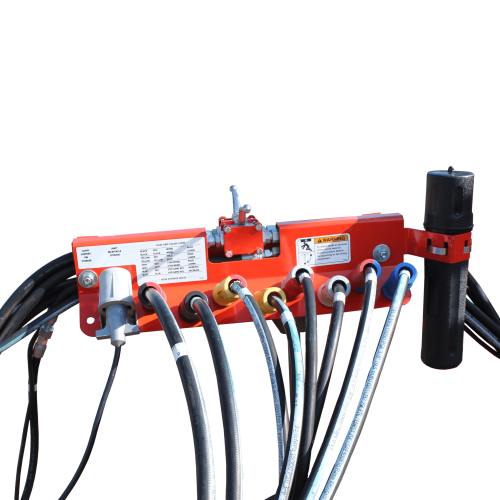

Tractor Interface Center

The tractor interface center prevents hydraulic hoses from binding in turns and adds operator convenience. Includes hose routing chart, color coded hose grips, storage for light hookup and owner’s manual.

SPECIFICATIONS

| Transport Width |

|---|

| Frame Type |

| Number of Disc Blades |

| Number of Bearing Arms |

| Working Width |

| Weight |

| Disc Blade Spacing |

| Disc Gang Angle |

| 8100-12N | 8100-12W | 8100-14N | 8100-14W | 8100-15N | 8100-15W | 8100-16N | 8100-18W |

|---|---|---|---|---|---|---|---|

| 13’11” (4.2 m) | 13’10” (4.2 m) | 15’2″ (4.6 m) | 15’4″ (4.6 m) | 16’5″ (5 m) | 16’10” (5.1 m) | 17’9″ (5.4 m) | 19’8″ (6 m) |

| Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid |

| 38 | 34 | 42 | 38 | 46 | 42 | 50 | 50 |

| 8 | 8 | 8 | 8 | 12 | 12 | 12 | 12 |

| 12’4″ (3.7 m) | 12’3″ (3.8 m) | 13’7″ (4.1 m) | 13’9″ (4.2 m) | 14’10” (4.5 m) | 15’3″ (4.6 m) | 16’2″ (4.9 m) | 18’1″ (5.5 m) |

| 4,624 lb (2 097 kg) | 4,456 lb (2 021 kg) | 4,889 lb (2 218 kg) | 4,722 lb (2 142 kg) | 5,317 lb (2 412 kg) | 5,154 lb (2 338 kg) | 5,546 lb (2 516 kg) | 5,627 lb (2 552 kg) |

| 8″ (20.3 cm) | 9-1/8″ (23.2 cm) | 8″ (20.3 cm) | 9-1/8″ (23.2 cm) | 8″ (20.3 cm) | 9-1/8″ (23.2 cm) | 8″ (20.3 cm) | 9-1/8″ (23.2 cm) |

| Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees | Front 15, 18, 21 Degrees, Rear 12, 15, 18 Degrees |

| Hitch Type |

|---|

| Leveling |

| Hydraulics |

| Depth Control |

| Disc Gangs |

| Disc Blades |

| Taper Blades |

| Disc Scrapers |

| Rear Hitch |

| Tires |

| Transport Locks and Safety |

| 8100-12N | 8100-12W | 8100-14N | 8100-14W | 8100-15N | 8100-15W | 8100-16N | 8100-18W |

|---|---|---|---|---|---|---|---|

| Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin | Combination 1-½” (38mm) Pin |

| Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling | Fore / Aft Mechanical Leveling |

| Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips | Color-Coded Hydraulic Hose Grips |

| Mechanical Stroke Control | Mechanical Stroke Control | Mechanical Stroke Control | Mechanical Stroke Control | Mechanical Stroke Control | Mechanical Stroke Control | Mechanical Stroke Control | Mechanical Stroke Control |

| 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Regreaseable SuperSeal Bearings |

| 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge | 22″ x 6 Gauge Residue Razor™ Solid Edge |

| Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler | Front 22″ – 20″, Rear 22″ – 20″ – 18″ – 16″ Bolt-On Furrow Filler |

| Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide | Adjustable 3.5″ / 8.9 cm Wide |

| Hitch Lug Weldment | Hitch Lug Weldment | Hitch Lug Weldment | Hitch Lug Weldment | Hitch Lug Weldment | Hitch Lug Weldment | Hitch Lug Weldment | Hitch Lug Weldment |

| (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs | (4) 9.5L x 15″ 8-Ply, Duals, 6-Bolt Heavy-Duty Hubs |

| Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign | Tongue Jack, High Visibility LED Lighting, Slow Moving Vehicle Sign |

| Recommended Operating Speed |

|---|

| Working Depth Range |

| Recommended Tractor Power |

| 8100-12N | 8100-12W | 8100-14N | 8100-14W | 8100-15N | 8100-15W | 8100-16N | 8100-18W |

|---|---|---|---|---|---|---|---|

| 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) | 4 – 6 mph (6 – 9 km/h) |

| 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) | 2 – 5″ (5 – 12.7 cm) |

| 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) | 6 – 9 ENG HP/ft (14 -23 kW/m) |

| Recommended Operating Speed |

|---|

| Working Depth Range |

| Recommended Tractor Power |

| 7305-18N | 7305-18W | 7305-18NR | 7305-18WR | 7305-21N | 7305-21W | 7305-21NR | 7305-21WR | 7305-24N | 7305-24W | 7305-24NR | 7305-24WR | 7305-27N | 7305-27W | 7305-27NR | 7305-27WR | 7305-31N | 7305-31W | 7305-31NR | 7305-31WR | 7305-34N | 7305-34W | 7305-34NR | 7305-34WR |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) | 5 – 7 mph (8 – 11 km/h) |

| 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) | 2″ – 5″ (5 – 12.7 cm) |

| 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) | 7 – 11 ENG HP/ft (17 – 26 kW/m) |

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com