Retain Residue, Remove Compaction

The 4835 in-line ripper provides efficient compaction removal, while allowing crop residue to remain virtually undisturbed on the surface. Working widths ranging from 10’ to 27’6”, and a variety of shank and point options are available to meet your agronomic needs.

The KUHN Krause 4835 in-line ripper is the ideal tool to fight soil compaction, one of the leading causes of yield reduction. With working depths of 8” to 16”, the 4835 provides aggressive soil fracturing, while retaining valuable crop residue on the field surface. This allows for greater root development and water infiltration into the soil, and effectively reduces runoff and soil erosion. KUHN Krause 4835 in-line rippers are available in rigid 4- to 7-shank models or folding 7- to 11-shank models with choice of 30”, 36”, 38” or 40” shank spacing dependent upon model. The 4835 can be equipped with spring reset, Pathfind’r™ or rigid, shear-bolt protected shanks for soils where rock is not a concern. A variety of shanks and points are available depending on your agronomic needs.

YOUR BENEFITS

3-Point or Pull-Type Configurations

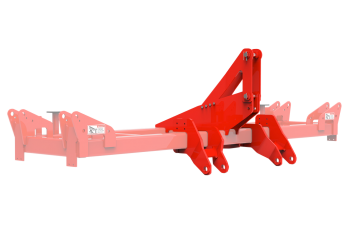

3-Point Hitch

Designed for deep tillage with strength and durability in mind. Category 3, 3N, 4 & 4N 3-point hitch configurations are available dependent on machine configuration. 3-point hitches are integrated into a two-bar frame design with main members of heavy-duty, 6”x6” structural steel tubing.

Rear Lift Drawbar Pull-Hitch

Rear lift pull-hitch option available for all 4835-530F through 4835-1130F models for transport stability. The drawbar pull-hitch includes 280/70 R15 tires on the rear lift and 280/70 R15 front mounted gauge wheel tires.

Shank Mounts to Match Your Field Conditions

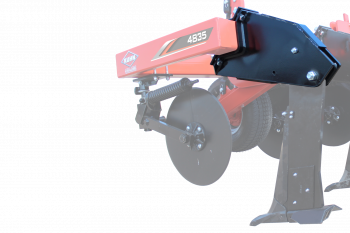

Shear-Bolt

Rigid, shear-bolt mounts are an economical choice for soils where rocks or other obstacles are not a concern. Shear-bolt protection guards against shank damage from unexpected obstacles.

- Shear force: 10,000 pounds (approximate)

- 16” maximum shank working depth

- For non-rock conditions

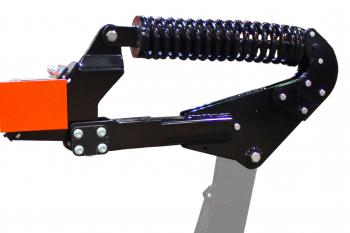

Spring Reset

Recommended for field conditions where obstacles or rocks may be encountered. A 4”x4” welded tube provides strength.

- 2,500 pound point load

- 20” trip height

- 16” maximum shank working depth

- 36” underframe clearance

PathFind’R™

Exclusive pivoting design allows the shank to deflect up to 6 degrees on each side for a total of 12 degrees of movement.

- Basic spring reset design

- Makes deep ripping possible on contours or terraces

- Deflects impacts improving performance in rocky soils

- Smoother steering under full power with tracked tractors

- Reduces stress on implement frame and 3-point tractor hitch

- Not compatible with pull-type hitch

- 20” trip height

- 16” maximum shank working depth

- 36” underframe clearance

Shank & Point Options

A Variety of Options

The 4835 in-line ripper may be configured in many different ways to achieve your agronomic goals. Choose from a variety of shank, point and wing combinations to achieve your desired field finish. Surface field finish is primarily determined by the type of shank used with parabolic offering the most soil disturbance, followed by MRD and no-till. Compaction removal, residue incorporation and draft are determined by points and shank caps.

No-Till Shank, Points and Wings

- Choice of ¾” no-till shank (normal conditions) or 1” no-till shank (extreme conditions)

- Austempered wear bar

- Choose from 1-3/4″ or Double K® chromium carbide points with either 8” wing or low disturbance shank cap

Pictured: ¾” no-till shank with Double K chromium carbide point and low disturbance shank cap (left), 1” no-till shank with 1-3/4” point and 8” wing (right)

Conservation Tillage Shanks & Points"

- 1-1/4″ MRD (minimum residue disturbance) shank

- Austempered wear bar

- • Choice of Double K 7” wing ripper point or Double K 2-1/2” straight ripper point

Pictured: 1-1/4” MRD shank with Double K 2-1/2” straight ripper point (left), 1-1/4” MRD shank with Double K 7” wing ripper point (right)

Conventional Tillage Shanks & Points"

- Parabolic shank

- Chrome wear bar or coverboard

- Choice of Double K 2-1/2” straight ripper point or Double K 7″ wing ripper point

Pictured: Parabolic shank with 2-1/2” straight ripper point and chrome wear bar (left), Parabolic shank with 7” wing point with cover board (right)

EQUIPMENT

Gauge Wheels

Ratchet-jack adjustable depth gauge wheels are standard equipment on the 4835. These 20.5” x 8” load range E tires, on 5-bolt hubs, maintain uniform depth in varying field surfaces and soil types.

Coulters

Heavy-duty, 22-inch diameter x ¼” thick coulters are standard on each row of all 4835 in-line rippers. These rugged coulters feature 450 pounds of down pressure to slice through the toughest crop residues. Coulter hubcaps are secured with metal retainers to ensure bearing protection.

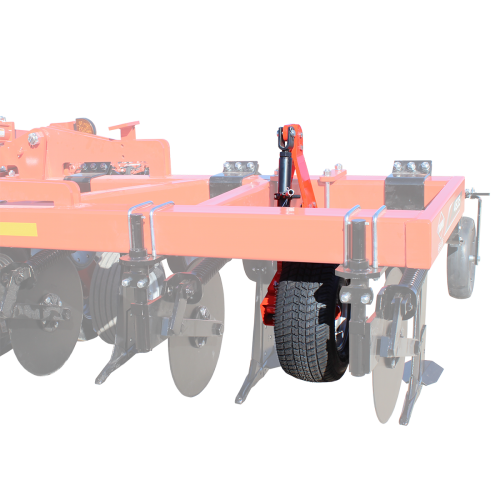

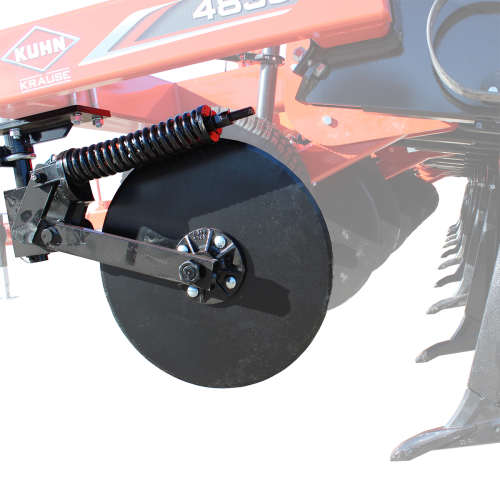

Closing Wheel Attachment

Designed to further limit soil blowout, optional closing wheels operate independently of shank depth maintaining constant soil contact close to the shank. Closing wheels are easily adjustable for operating position in relation to the ripper shank and down pressure.

SPECIFICATIONS

| Transport Width |

|---|

| Frame Type |

| Number of Shanks |

| Shank Spacing |

| Working Width |

| Spring Reset Shank Weight |

| Shear-Bolt Shank Weight |

| 4835-430R | 4835-440R | 4835-530R | 4835-630R | 4835-636R | 4835-638R | 4835-640R | 4835-730F | 4835-730R | 4835-830F | 4835-836F | 4835-838F | 4835-840F | 4835-930F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9’2″ (2.8 m) | 11’8″ (3.6 m) | 11’8″ (3.6 m) | 14’5″ (4.4 m) | 16’10” (5.1 m) | 18’5″ (5.6 m) | 18’5″ (5.6 m) | 12’6″ (3.8 m) | 16’10” (5.1 m) | 12’4″ (3.8 m) | 14’5″ (4.4 m) | 14’5″ (4.4 m) | 14’5″ (4.4 m) | 14’5″ (4.4 m) |

| NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar | NEW Heavy-Duty Toolbar 6″ x 6″ Double Rank Toolbar |

| 4 | 4 | 5 | 6 | 6 | 6 | 6 | 7 | 7 | 8 | 8 | 8 | 8 | 9 |

| 30″ (76 cm) | 40″ (101.6 cm) | 30″ (76.2 cm) | 30″ (76.2 cm) | 36″ (91.4 cm) | 38″ (96.5 cm) | 40″ (101.6 cm) | 30″ (76.2 cm) | 30″ (76.2 cm) | 30″ (76.2 cm) | 36″ (91.4 cm) | 38″ (96.5 cm) | 40″ (101.6 cm) | 30″ (76.2 cm) |

| 10′ (3 m) | 13’4″ (4.1 m) | 12’6″ (3.8 m) | 15′ (4.6 m) | 18′ (5.5 m) | 19′ (5.8 m) | 20′ (6.1 m) | 17’6″ (5.3 m) | 17’6″ (5.3 m) | 20′ (6.1 m) | 24′ (7.3 m) | 25’4″ (7.7 m) | 26’8″ (8.1 m) | 22’6″ (6.8 m) |

| 3,900 lb (1 768 kg) | 4,314 lb (1 956 kg) | 4,848 lb (2 198 kg) | 5,563 lb (2 522kg) | 5,756 lb (2 610 kg) | 5,900 lb (2 675 kg) | 5,900 lb (2 675 kg) | 7,300 lb (3 311 kg) | 6,882 lb (3 121 kg) | 7,800 lb (3 538 kg) | 8,464 lb (3 839 kg) | 8,464 lb (3 839 kg) | 8,464 lb (3 839 kg) | 8,813lb (3 998 kg) |

| 3,100 lb (1 406 kg) | 3,514 lb (1 594 kg) | 3,848 lb (1 745 kg) | 4,363 lb (1 979 kg) | 4,556 lb (1 979 kg) | 4,700 lb (2 132 kg) | 4,700 lb (2 132 kg) | 5,900 lb (2 676 kg) | 5,482 lb (2 487 kg) | 6,200 lb (2 812 kg) | 6,851 lb (3 108 kg) | 6,851 lb (3 108 kg) | 6,851 lb (3 108kg) | 6,993 lb (3 172 kg) |

| Hitch Type |

|---|

| Coulter Blades |

| Shank Mount |

| Shanks |

| Points |

| Shattering Wing |

| Depth Control |

| Gauge Wheels |

| Transport Locks and Safety |

| 4835-430R | 4835-440R | 4835-530R | 4835-630R | 4835-636R | 4835-638R | 4835-640R | 4835-730F | 4835-730R | 4835-830F | 4835-836F | 4835-838F | 4835-840F | 4835-930F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Small Frame: CAT 3N, 3 and 4N Compatible with Parking Stands | Large Frame: CAT 4N, and 4 Compatible with Parking Stands | Large Frame: CAT 4N, and 4 Compatible with Parking Stands | Large Frame: CAT 4N, and 4 Compatible with Parking Stands | Large Frame: CAT 4N, and 4 Compatible with Parking Stands |

| 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure | 22″ x ¼” Smooth, 450 lb (250 kg) Down Pressure |

| Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height | Spring Reset: 2,500 lb Point Load, 20″ Trip Height |

| No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | No-Till Shank, ¾” Thick (Very Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors |

| 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) | 1-¾” Austempered Ductile Points (No-Till Shanks Only) |

| 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings | 8″ Austempered Shattering Wings |

| Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels | Ratchet Jack Adjustable Gauge Wheels |

| (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E | (2) 20.5″ x 8″, Load Range E |

| Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit | Slow Moving Vehicle Sign, High Visibility LED Transport Light Kit |

| Hitch Type |

|---|

| Shank Mount |

| Shank Mount |

| Shanks |

| Shanks |

| Shanks |

| Points |

| Points |

| Points |

| Shank Cap |

| Wing Gauge Wheels |

| Closing Wheels |

| Shank Stagger Kit |

| 4835-430R | 4835-440R | 4835-530R | 4835-630R | 4835-636R | 4835-638R | 4835-640R | 4835-730F | 4835-730R | 4835-830F | 4835-836F | 4835-838F | 4835-840F | 4835-930F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Not Applicable | Not Applicable | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (2) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (4) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (4) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (4) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) | Drawbar Pull Hitch with Rear Lift Wheels, Includes (4) 280/70R15″ Tires, Duals, (4) 280/70R15″ Front Mounted Gauge Wheels, (1) 4″ x 16″ and (1) 4-½” x 16″ Cylinder, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses, Tongue Jack, CAT IV Hitch, Safety Chain (Less Parking Stands) |

| Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) | Rigid: Shear-Bolt Protected, 10,000 lb (Shear Force) |

| Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) | Pivoting PathFind’r™ Spring Reset, 2,500 lb (Not Compatible with Pull Hitch) |

| MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar | MRD Shank, 1-¼” Thick (Minimum Residue Disturbance), Austempered Wear Bar |

| HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors | HD No-Till Shank, 1″ Thick (Low Surface Disturbance), Austempered Wear Bar, Chromium Carbide Shank Side Protectors |

| Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option | Parabolic Shank, 1-¼” Thick, Chromium Carbide Wear Bar or 6″ Coverboard Option |

| Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) | Double K® 2″ Chromium Carbide Points (No-Till Shank Only) |

| Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points | Double K® 7″ Wing Ripper Points |

| Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point | Double K® 2-½” Straight Ripper Point |

| Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) | Low Disturbance Shank Cap (In Lieu of Wing) |

| Not Applicable | Not Applicable | Not Applicable | Not Applicable | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2)” x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) | (2) 20.5″ x 8″, Load Range E (One per Wing) |

| (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) | (2) 4 x 16″ Smooth Closing Wheels per Shank, Adjustable Spring Tension (Limit Shank Soil Blowout) |

| Not Applicable | Not Applicable | 12″ Offset Between Shanks | Not Applicable | Not Applicable | Not Applicable | Not Applicable | 12″ Offset Between Shanks | 12″ Offset Between Shanks | Not Applicable | Not Applicable | Not Applicable | Not Applicable | 12″ Offset Between Shanks |

| Recommended Operating Speed |

|---|

| Working Depth Range |

| Recommended Tractor Power |

| 4835-430R | 4835-440R | 4835-530R | 4835-630R | 4835-636R | 4835-638R | 4835-640R | 4835-730F | 4835-730R | 4835-830F | 4835-836F | 4835-838F | 4835-840F | 4835-930F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) | 4 – 7 mph (6 – 11 km/h) |

| 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) | 8″ – 16″ (20.3 – 40.6 cm) |

| 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) | 35 – 50 ENG HP/shank (26 – 38 kW/shank) |

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com