The H-1130 Big Bite tub grinder is Haybuster’s heavy-duty PTO grinder.

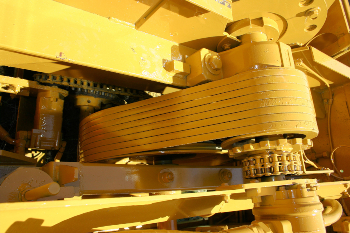

It is designed with the features and the durability you need in a 11’ tub grinder. Some of these features include tub tilt, heavy hammermill with ½” plates and ½” hammers along with 1 ¼” rods, dual augers and a 26’ long stacking conveyor. The 315 hp drive system consists of an 8-groove belt/pulley system powered through a 77 series PTO driveline. The belt system tension is set at the factory and is designed to maintain its desired tension when stretching.

Standard Features

- The dual 12” belly augers are suspended by two heavy-duty bearings and are located at the base of the newly-designed screen area. The auger system allows for a sealed under-screen discharge area. The larger discharge area also provides for higher capacities and reduces the potential for plugging.

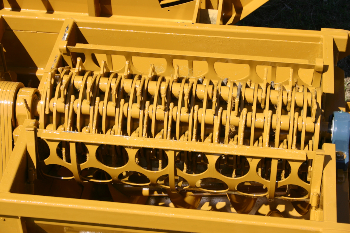

- The Big Bite 50” heavy-duty hammermill is now standard equipment and is located at the rear of the tub to reduce the length of the discharge. This, along with the increased area around and under the screens accelerates product discharge and reduces the potential of plugging. The heavy-duty hammermill operates at 2140 rpm and is constructed with 88 ½” swinging hammers. The hammers are hardened and are held in place with 1 ¼” case-hardened hammer rods. The hammermill is mounted on a 3 ½” stressproof shaft supported by 3 ¼” bearings.

- The DuraTech electronic governor slows protection for the tractor and the machine. This governor maintains a constant load on the tractor and driveline by adjusting the tubs rpm which controls the feed rate of the material to the hammermill.

- The belt drive system for the hammermill has 8-5 VP belts to handle the increased rotor speed and increased horsepower capacity. The spring tension belt drive automatically adjusts belt tension as the belts stretch.

- The tub drive has continuous teeth around the tub and dual spring tensioners. Power is provided by a single hydraulic motor controlled by the electronic governor.

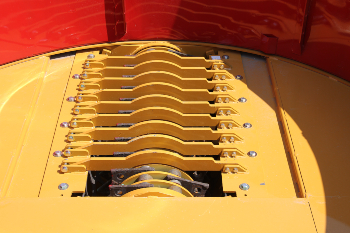

- The new heavy-duty bolt-in mill grate/9 bar mill grate combination is designed to allow the operator the ability to change the number of mill grate bars and slug bars as grinding conditions change

- The large H-1130 Big Bite Tub is constructed of a 10-gauge steel floor and a 12-gauge steel side wall. The width of the tub is 11’ 3”, is 50” deep and can handle the largest round and square bales.

- The H-1130’s tub opens a full 90 degrees for easy access to the hammermill and drive train for service and maintenance.

- The hydraulic folding 24” wide by 26’ long high-capacity stacking conveyor is designed for the increased capacity of the H-1130. It can stack material 18’ 6” high.

- Large 16.5 x 16.1, 14-ply flotation implement tires provide for easy transportation and a solid base for the H-1130.

- High-capacity grain grinding can also be done with the H-1130 tub grinder. Just add in the grain hopper and changes the screens and you have a high capacity grain grinder for grinding and/or cracking feed grains.

Optional Features

PTO Shaft -1000 RPM

Tractor Half, 1-3/4 in, 20 Spline Shaft

Tractor Half, 1-3/8 in, 21 Spline Shaft

Hammermill Feeding

Slug Buster, 5 tooth screen hold down Bolt in Mill grate/slug bar for grinding tough hay or crop residue.

Geyser Plates

Geyser Plate Kit, use with the Slug Buster

Geyser Plate Kit, slotted, use with the Mill Grate

Hopper for Grain Grinding

Ear Corn Kit

Better diets for dairy cows – an article from the USDA -describes how finely ground grains/corn can offer a better diet for cows.

Closed Center Conversion Kit

This kit is required to operate the conveyor lift valve properly, with John Deere 60 and older series tractors.

Grinding Screens

1/8 in. (3.18 mm) Round Hole Screen Half*

3/16 in. (4.76 mm) Round Hole Screen Half**

1/4 in. (6.35 mm) Round Hole Screen Half

3/8 in. (9.52 mm) Round Hole Screen Half

1/2 in. (12.7 mm) Round Hole Screen Half

5/8 in. (15.88 mm) Round Hole Screen Half

3/4 in. (19.05 mm) Round Hole Screen Half

1 in. (25.4 mm) Round Hole Screen Half

1-1/2 in. (38.1 mm) Round Hole Screen Half

2 in. (50.8 mm) Round Hole Screen Half

3 in. (7.62 cm) Round Hole, Screen Half (standard)

4 in. (10.16 cm) Round Hole, Screen Half (standard)

5 in. (12.70 cm) Round Hole, Screen Half (standard)

6 in. (15.24 cm) Round Hole, Screen Half (standard)

7 in. (17.78 cm) Round Hole, Screen Half (standard)

8 in. (20.32 cm) Round Hole, Screen Half (standard)

Dummy (Open) Screen Half

*1/8 in. (3.18 mm) thick,

**3/16 in. (4.76 mm) thick, all other screens are 1/4 in. (6.35 mm) thick

FEATURES & BENEFITS

SPECIFICATIONS

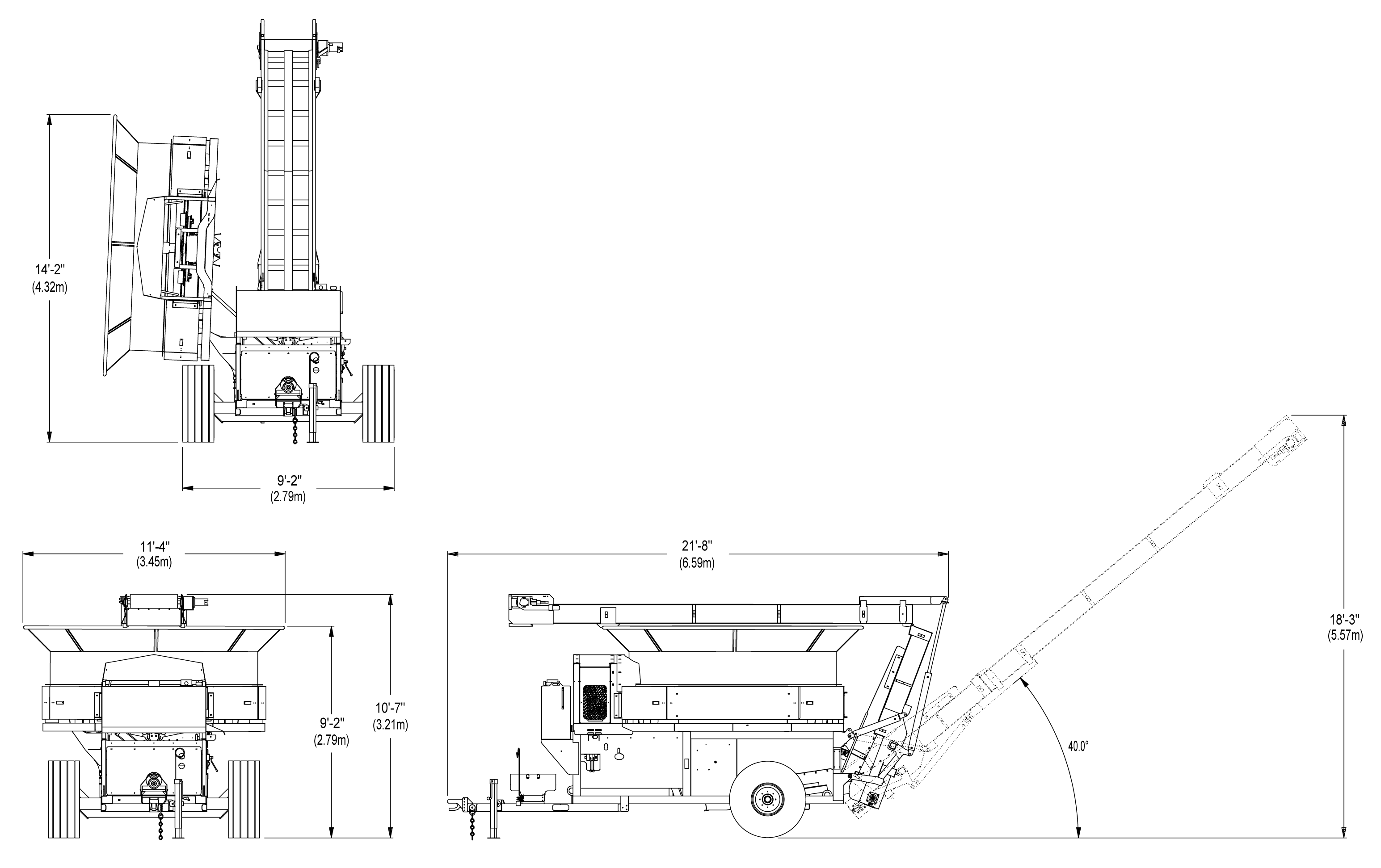

| WEIGHT | |

|---|---|

| Total | 14,500 lbs, (6,032.78 kg) |

| Hitch (with conveyor folded) | 1,925 lbs. (873.2 kg) |

| TRANSPORT DIMENSIONS | |

| Width | 11′ 4′ (3.45 m) |

| Height | 10′ 7″ (3.2 m) |

| Length | 21′ 8″ (6.6 m) |

| OPERATING DIMENSIONS | |

| Total Width | 11′ 3″ (3.43 m) |

| Total Width, Tub Raised | 12′ 6″ (3.81 m) |

| CHASSIS FEATURES | |

| Towing Arrangement | Clevis hitch |

| Tires | 2) 16.5L X 16.1 (14 ply) High Flotation Implement Tires |

| Wheels | (2) 16.1 X w14C – 8 Bolt, 6″ (15.24 cm) Pilot |

| Bearings | Tapered roller |

| TUB FEATURES | |

| Loading Height | 9′ 2″ (2.79 m) |

| Tub Width at Flare | 11′ 3″ (3.43 m) |

| Depth | 50″ (1.27 m) |

| Tub Inside dia at Base | 8′ 11″ (2.72 m) |

| Tub Wall Thickness | 12 gauge (2.66 cm) |

| Tub Floor Thickness | 10 gage (3.42 mm) |

| HAMMERMILL – HEAVY DUTY | |

| Length | 50″ (127 cm) |

| Diameter, Hammers Extended | 26″ (66.04 cm) |

| Feed Opening | 28” x 52” (71.1 cm X 132.08 cm) |

| Hammers | HD-1/2″ (12.7cm) A.B. Hardened Steel, Swing |

| Number of Hammers | 88 |

| Hammer Rods | 1-1/4″ (31.75 mm), Case Hardened Steel |

| Cylinder Plates | HD Mills, 1/2″ (12.7 mm) thick X 15.75″ (40.01 cm) |

| Cylinder Shaft | 3 1/2″ (8.98 cm) Stress Proof Steel |

| Bearings | 3 1/4″ (8.26 cm) Pillow Block |

| Drive | PTO through Multiple V-Belts, 1,000 RPM, 1-3/8″ dia. 21 spline shaft, or 1-3/4″ dia. 20 spline shaft |

| Screens | 1/8″ (3.18 mm), 3/16″ (4.76 mm), or ¼” (6.35 mm) Thick and Various Hole Sizes from 1/8″ (3.18 mm) to 8″ (203.2 mm) – Must Order 2 Screens of Choice With Machine-Not Standard equipment |

| BELLY AUGERS | |

| Type | Twin 12″ (30.48 cm diameter – 4′-6″(1.37 m) long) |

| Drive | Hydraulic |

| DISCHARGE CONVEYOR | |

| Type | Rubber Belt with Cleats |

| Drive | Hydraulic |

| Drive & Idler Roller Type | Rubber Lagged Drive, “Easy Clean” Idler |

| Length | 26′ (7.92 m) |

| Width | 24″ (60.69 cm) |

| Maximum Conveyor Lift Height | 18′ 6″ (5.64 m) @ 40 Degree Incline Conveyor Lift |

| Conveyor Lift & Fold | Hydraulic |

| OPERATOR CONTROLS | |

| Tub Rotation | 3 Position Hydraulic Valve; Clockwise, Stop, Counter Clockwise |

| Tub Speed | DuraTech Model RCB93 Electronic Governor Stabilizes Engine Load by Adjusting Tub Rotation Speed |

| Conveyor Lift | 3-Position Hydraulic Valves for Raise, Hold and Lower |

| Conveyor Fold | 3-Position Hydraulic Valves for Fold, Hold and Unfold |

| Conveyor On/Off | 2-Position Hydraulic Valves for Forward/Off |

| Tub Tilt | Tractor Hydraulic |

| REQUIREMENTS FOR OPERATION TRACTOR | |

| PTO Horsepower Required | 200 HP (149.1 kw) to 315 HP (234.90 kw) |

| Min. Hydraulic Output | 8 gpm at 1,500 psi (30.3 lpm. x 10,345 kPa) |

| Hydraulic Remote Controls | 2- Double Acting Valves with Quick Coupler Outlets |

| Electrical | 12 VDC |

| ELECTRIC MOTORS | |

| 300 HP (223.7 kw) Drive Motor, 10 HP (7.5 kw) Hydraulic Drive Voltages Available: 460V-60Hz, 380V-50Hz, 380V-60Hz, 575V-60Hz Electric Motors require three phase power – PLEASE CHECK WITH YOUR POWER SUPPLIER FOR THE PROPER VOLTAGE AND HZ FOR YOUR AREA |

|

| GRINDER | |

| Hydraulic Reservoir Capacity | 60 gallons (227.13 L) of Hydraulic Oil (Mobile 423, CENEX Super HTB or Equivalent) |

| Mill Grate Kit | This kit includes; 5 removable mill grates, and 6 removable slug bars for improved grinding performance in tough hay and stover |

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com