Big Benefits in a Small Package

KUHN Knight PS 235 and 242 ProSpread® apron box spreaders are non-commercial spreaders that provide an affordable option for producers without sacrificing quality. With capacities of 275 and 360 ft³, these machines are ideal for small dairy, feeder, and cow/calf operations.

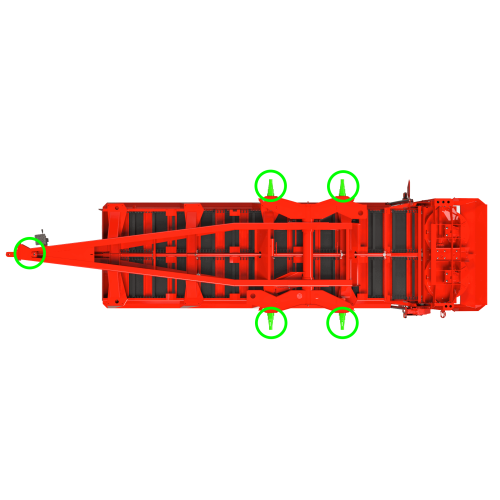

KUHN Knight PS 235 and 242 ProSpread® apron box spreaders are non-commercial spreaders that provide an affordable option for producers without sacrificing quality. The PS 235 and PS 242 are designed for small dairy, feeder, and cow/calf operations that process a wide array of semi-solid and solid materials. An all-steel welded box construction and two-piece poly floor give you a machine that is built to last. Choose between horizontal, VertiSpread® vertical beaters or the AccuSpread® spinner discharge to best fit the spreading needs of your operation. These spreaders, with heaped capacities of 275 and 360 ft³, feature a low loading height, are easy to maneuver around the farm and provide more efficient use of manure with exceptional spreading and metering capabilities.

YOUR BENEFITS

EQUIPMENT

Additional Equipment for the SLC 100 Series

Optional Scales Package

The PS 242-270 can be paired with a scale package which allows the operator to precisely manage and track manure applications. A five-point scale platform provides increased accuracy and durability.

Thrown Object Shield

The thrown object shield, standard with vertical and spinner beaters, better protects the tractor and driver from flying debris. The grated design allows for easy viewing of the unloading process. Optional extensions (shown in the photo) provide greater protection by increasing both height and width.

Manual Flow Control

For tractors that don’t have flow control capabilities, the manual flow control allows the operator to easily adjust the apron speed to suit specific materials or speeds. This increases flexibility when spreading a variety of materials.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com