Maximum Spreading Efficiency

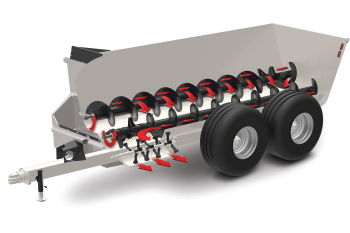

Maximize your productivity and performance with the KUHN Knight SLC 100 Series ProTwin® Slinger® manure spreaders. Truck-mount and trailer models are available with capacities ranging from 2,600 to 5,000 gallons.

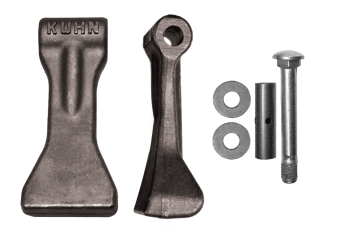

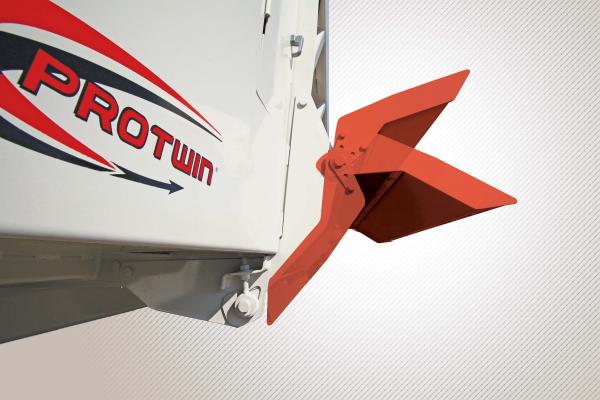

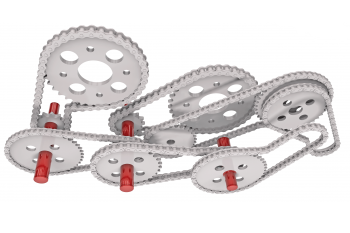

KUHN Knight SLC 100 Series ProTwin® Slinger® commercial manure spreaders set the standard for fast, efficient spreading. Maximize your productivity and performance with our large-capacity truck-mount or trailer models. The unique twin-auger design and exclusive v-body construction allow the Slinger to handle the widest variety of materials compared to any spreader on the market. Complete adjustability of the wide discharge improves material breakup for more consistent, even spreading. New hammers are designed for less wear and longer life. These spreaders provide the ideal combination of efficiency, versatility, and rugged durability to give you maximum return for your equipment dollars. If you need one machine to handle all of your diverse spreading needs, look to the SLC 100 Series ProTwin Slinger manure spreaders.

YOUR BENEFITS

EQUIPMENT

Additional Equipment for the SLC 100 Series

Truck Mount Models

The SLC 132 and 141 are available as a truck mount for applications requiring longer travel distances. Mechanical and hydrostatic drive options are available.

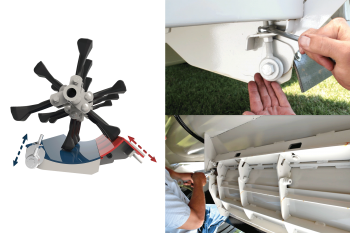

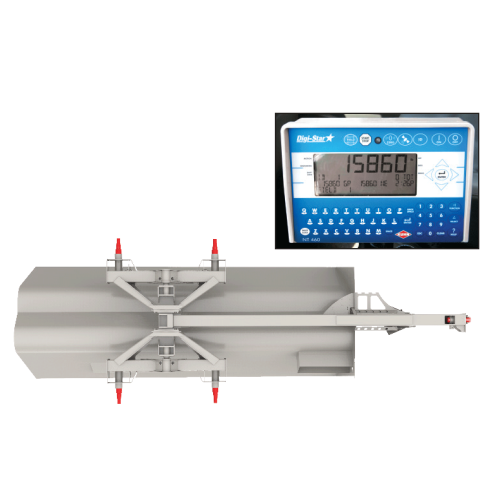

Scale System

A scale system is available for all SLC models, providing accurate application and tracking of applied nutrients. This system, combined with the latest scale head technology, provides integrated manure application management and record keeping capabilities. Trailer models feature a 5-point system of four weigh bars in the wheel spindles and one in the hitch. Truck models use a 3-point system.

Hydraulic Disc Brakes

Hydraulic disc brakes are optional for SLC 126, 132, 141 models and standard on SLC 150 trailer models. Brakes provide additional stopping capabilities for faster stopping of the heavy loads hauled by these high-capacity machines.

Hydraulic Lid

The lid can be raised and lowered hydraulically and provides secure closure to haul slurry-type materials. While it is not completely water tight, it does an excellent job helping to contain semi-liquid materials without worry of spills during transport.

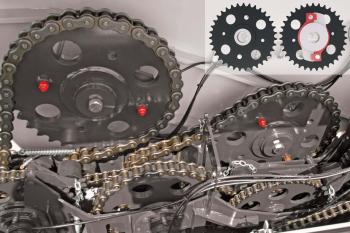

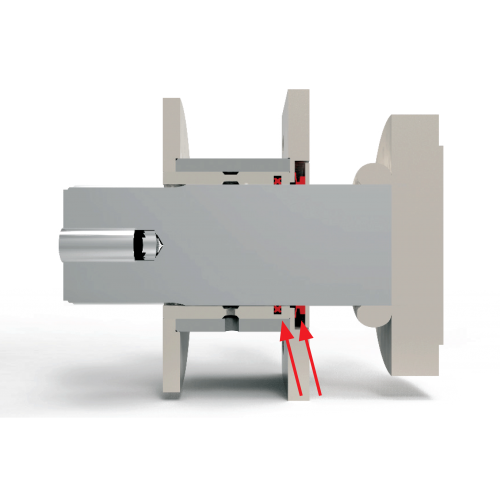

Dual-Seal Bearings

Dual-seal bearings are designed to keep liquid in the tank and away from the critical drive components. With these seals, liquid manure and other caustic liquids are less able to penetrate the Nylatron bearings or contaminate the oil bath reservoir.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com