Versatile, Efficient & Reliable

If you need one machine to handle all of your diverse spreading needs, look to the KUHN Knight SL 100 Series ProTwin® Slinger® manure spreaders. Four trailer models are available with capacities ranging from 1,000 to 2,400 gallons.

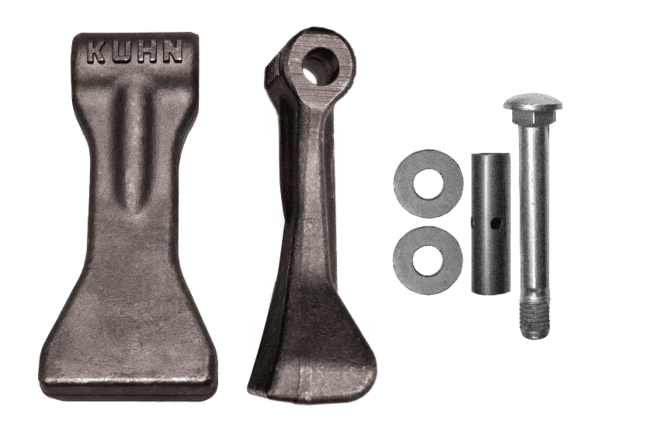

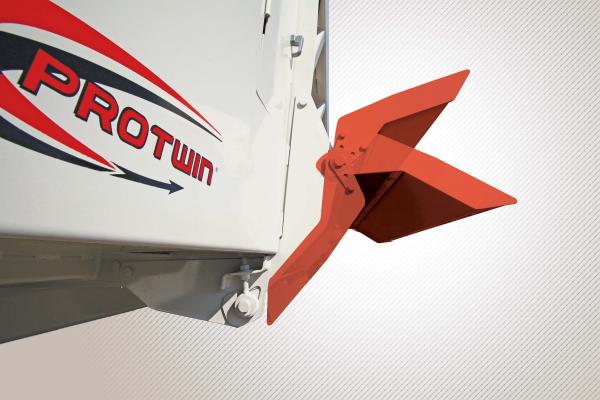

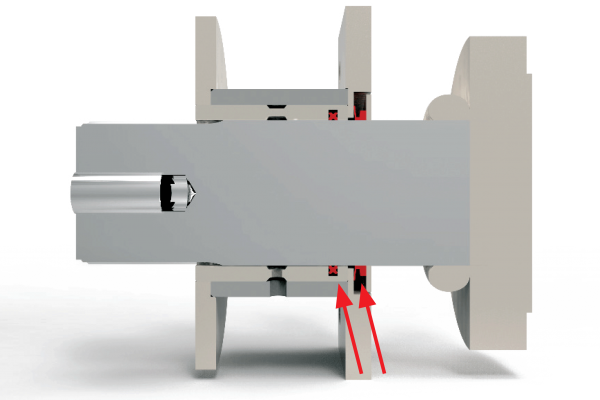

KUHN Knight SL 100 Series ProTwin® Slinger® manure spreaders offer next level performance and reliability to give you maximum return for your equipment dollars. The unique ProTwin twin-auger design and exclusive v-body construction allow the Slinger spreader to handle the widest variety of wet and dry materials, compared to any spreader on the market. Complete adjustability of the discharge shroud greatly improves material breakup for more consistent, even spreading. A new hammer design provides more wear surface on the bottom edge to extend hammer life. If you need one machine to handle all of your diverse spreading needs, look to the SL 100 Series.

The SL 110 is also offered in an orchard/vineyard model to meet specific growers’ needs. This model features a hydraulic deflector with rubber extension, which provides accurate material placement while adding some forgiveness necessary in narrow row spacing. This model also features a narrow 10.5L tire and CV PTO making it very maneuverable in tight locations.

YOUR BENEFITS

EQUIPMENT

Hydraulic Lid

The lid, available on the SL 124, can be raised and lowered hydraulically and provides secure closure to haul slurry-type materials. While it is not completely water tight, it does an excellent job helping to contain semi-liquid materials without worry of spills during transport.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com