Time-Tested Design

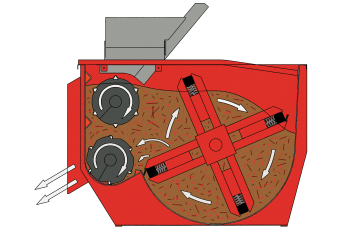

KUHN Knight 3100 Series Reel Auggie® mixers offer the same quality mixing performance and dependable service that has been their hallmark. The time tested, standard reel and auger design provides a fast, thorough mix for a fluffy, palatable ration.

KUHN Knight 3100 Series Reel Auggie® mixers offer the same quality mixing performance and dependable service that has been their hallmark. The time tested, standard reel and auger design provides a fast, thorough mix for a fluffy, palatable ration. Quality components and a rugged design help ensure reliability and long life. These mixers are available in trailer, truck and stationary models with capacities ranging from 150 to 200 ft³. These machines also offer a low standard loading height for easy loading with skid steers.

YOUR BENEFITS

EQUIPMENT

Hay Maxx® System

Hay Maxx® System provides enhanced processing of a wide variety of materials. Hay and other bulky materials can be placed on the pan allowing them to be preprocessed by the upper auger before entering the mixing chamber. Additional aggressive, hardened-edge knives are added to the upper auger that help process the hay to the proper length before entering the mixing chamber.

Roughage Maxx® System

The optional Roughage Maxx System incorporates scalloped knives on the lower auger to maximize hay processing. The knives provide a more consistent particle length and more even blending. The result is a more uniform and palatable ration with reduced sorting for improved feed efficiency.

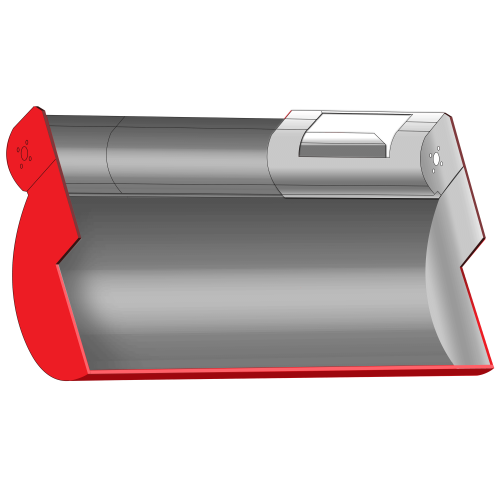

Full Stainless Steel Liner

Full Stainless Steel Liner A full stainless steel liner completely covers all of the high-wear areas for unmatched dependability and long service life. The liner provides added protection when mixing more abrasive or corrosive materials, resulting in longer life of the unit shell.

Flat Belt Conveyor

Different scale brands, models and options are available for all types of operations, ranging from the very basic to high-end feed-tracking programs that use a remote scoreboard display. Optional remote indicators are available for placement that will allow easier viewing.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com