Taking Efficiency…To The Maxx!

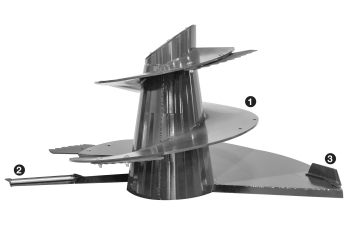

KUHN Knight VXL 100 Series triple-auger vertical mixers, with capacities ranging from 1,400 to 1,960 cubic feet, provide the ultimate solution for farmers to feed more cows per load by increasing the capacity without compromising mixing quality.

KUHN Knight VXL 100 Series Vertical Maxx® triple-auger mixers are rugged, yet simple to operate machines designed for large dairies that are looking to maximize efficiencies and feed more cows per load. Built to last in commercial operations and easy to maintain, the VXL allows you to spend more time at the bunk and less time in the shop. The VXL 100 Series is available in trailer and stationary configurations.

YOUR BENEFITS

EQUIPMENT

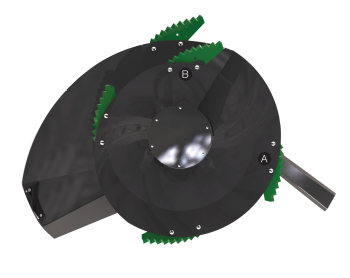

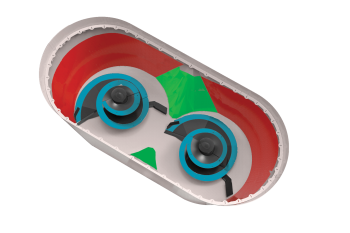

Stainless Steel Liner

A stainless steel side liner provides extra protection in the lower part of the chamber where most wear occurs. Stainless steel baffle liners are also available.

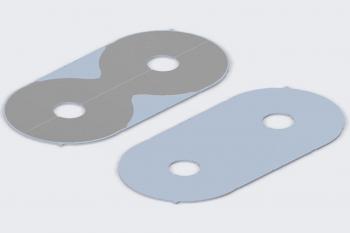

Capacity Belt Extension

A belt extension, added to the top of the mixing tub, increases capacity by about 10%. It also improves hay containment, and rubber construction is durable and pliable for long life.

Chain & Slat Conveyor

The flat, front conveyor option is simple to operate and offers convenient feeding from either side of the machine on trailer models. Hydraulic side shift is standard and gives you the ability to shift the conveyor a total of 16” from side to side for accurate feed placement.

If you’d like to add an option with magnets, choose a hanging belt or fixed tip-off. Either or both ends of the flat conveyor can be fitted with a hanging belt with magnets to catch small metal fragments. The hanging belt also helps to even feed flow off the end of the conveyor.

A fixed tip-off with magnets (shown) can be added to the flat, front conveyor. The magnets work to catch small metal fragments present in the feed and help prevent hardware disease.

Fixed Slide Tray

A simple, fixed tray is incorporated directly into the door frame and includes two strong magnets, as standard, to help catch any hardware to protect the health of the herd. The rubber belting helps direct the flow of feed for more accurate feed placement

Flat Belt Conveyor

Different scale brands, models and option are available for all types of operations, ranging from basic to high-end feed-tracking programs. Optional remote indicators are available for placement that will allow easier viewing.

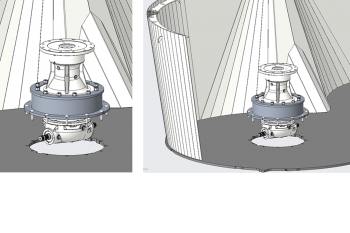

Rear Lift Assist

KUHN offers a 5-year prorated warranty on planetary and 2-speed gearboxes on all vertical mixers. KUHN also offers a 1-year warranty on all other machine components.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com