Tailored to Provide You Maximum Harvest Productivity

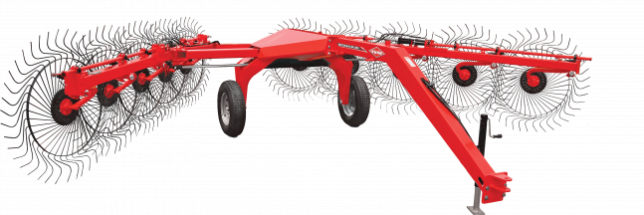

Available in 10-, 12- and 14-wheel configurations, the SR 300 Series SpeedRake® wheel rakes feature working widths ranging from 20’10” to 28’.

KUHN SR 300 Series SpeedRake® wheel rakes provide exceptional transportability and high-capacity raking to help you achieve optimum harvest productivity. The unique hybrid design, between a carted rake and a bi-fold rake, offers simplicity and high clearance, allowing you to tailor the machine to the needs of your operation. Individually floating, high-capacity rake wheel arms and a high-clearance frame offer clean raking and even crop flow for a fluffy, uniform windrow. The innovative hydraulic, parallel-folding design provides convenient operation from the tractor seat. Cantilever main raking beams eliminate the need for caster support wheels, which allows for raking closer to fences and other obstructions. The articulated rake beams allow for simple adjustment of windrow width while maintaining gentle crop flow to the windrow.

YOUR BENEFITS

EQUIPMENT

Raking Wheel and Hitch Extension

The SR 300 10-wheel model can be converted to a 12-wheel model with the Raking Wheel and Hitch Extension kit. This kit can easily be installed in the field. Note: The SR 312 cannot be converted to a 14-wheel model.

“V” Type Splitter Wheel

Excellent ground coverage ensures that all hay has been moved and also provides more complete pickup by a baler. The crop is split uniformly to each side for an even windrow formation, more consistent bale formation. This helps to fluff up the crop which results in faster drying.

Adjustable Clevis or Ball Hitch

A clevis hitch comes standard with all models. A ball hitch is optional.

Windguards

Windguards improve crop flow along the wheels for a more uniform windrow. The durable, HDPE guards are UV stable and improve raking performance in windy conditions. They also reduce wrapping in difficult conditions, such as tall, stemmy crop and corn stalks.

Tandem Axle

The tandem axles pivot up and down. This is a simple bolt on addition keeping the original tire. They are ideal for smooth and stable operation over difficult terrain.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com