Unequaled Spreading Precision

KUHN Axis® H-EMC-W .2 Series fertilizer spreaders offer a unique combination of innovative technologies to meet the desires of today’s farmers.

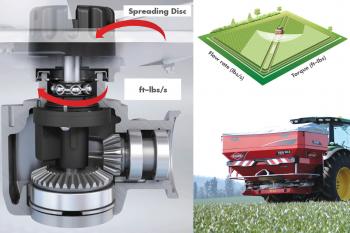

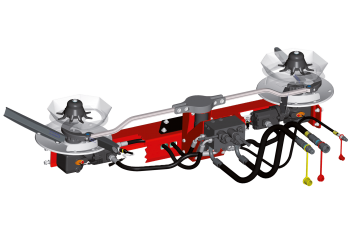

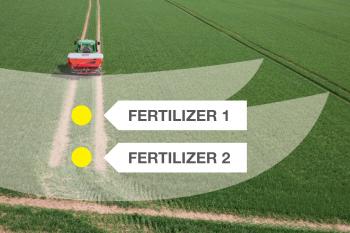

The KUHN Axis® H-EMC-W .2 Series sets the industry standard in precision broadcast fertilizer spreading. These fertilizer spreaders come with a variety of options to meet the needs of a wide range of producers up to large row crop or commercial operations. The Axis 40.2 and 50.2 fertilizer spreader models offer the most precise rate control in the industry, thanks to exclusive EMC technology. Triangular spread patterns create wide working widths and precise material placement, even in breezier conditions. Vari-Spread Pro, Opti-Point and border control combine to significantly reduce over-application to save input costs. ISOBUS software is simple to set up and the machine can be run with any terminal that meets the appropriate industry standards. All this adds up to an outstanding return on investment for you, the producer.

YOUR BENEFITS

EQUIPMENT

Axmat® System

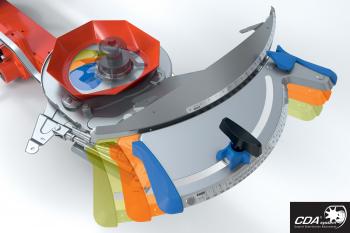

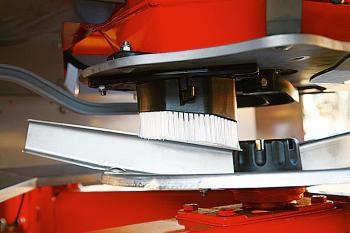

Available on the Axis® 50.2 H-EMC-W, the optional Axmat® system offers fully automatic, radar-based spreading adjustments. With 54 radar sensors positioned in a semi-circle below the spreading discs, Axmat scans the product leaving the disc paddles to recognize the location, character, and expansion of the spread pattern. Within fractions of a second, a new setting is calculated and applied if necessary. Thanks to the quick-reacting Speed Servo motors, the spread pattern is optimized every second by adjusting the drop point on each disc separately. With the Axmat system automatically detecting and compensating for changes in fertilizer properties and spreading conditions, you can be certain that nutrients are reaching all the right places in your fields.

ISOBUS Compatible

Operators have the ability to “plug and play” with existing ISOBUS virtual terminals for ultimate simplicity. The Axis® is variable rate ready without needing an additional rate controller. The KUHN CCI 50 and the CCI 1200 ISOBUS terminals are available on the Axis fertilizer spreader.

Axis® Cart – AC 100

The AC 100 Cart is a separate option to further enhance the versatility of any Axis spreader. The “hook and go” drawbar connection saves time, increases comfort, and allows tractors with lighter-duty hitches to safely utilize the machine. If a particular application calls for a mounted spreader, the Axis is easily removed from the cart. Single-axle versions have a track width adjustable from 80 – 90”, while tandem axle models offer fixed 90” spacing.

Fertilizer Level Windows

Two openings bring light inside the hopper so the fertilizer level is easily visible through the hopper windows.

Easy Hopper Access Ladder

Axis 50.2 models are equipped with ladders as standard for easier access to the hopper. For other models, ladders can be ordered as an option.

Parking Wheel

To be more flexible during attaching and detaching of your spreader, an optional parking wheel set is available. When mounted to the tractor, the wheels can be stored out of the way.

Quick Hitch

For 50.2 models, Quick Hitch brackets are available to allow the spreader to be attached to Cat. 3/4N Quick Hitches that meet current ASABE specifications. Mounting to a QH will move the spreader rearward approximately 12″ and additional front weight is advised for ballasting.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com