Handle no-till like a PRO!

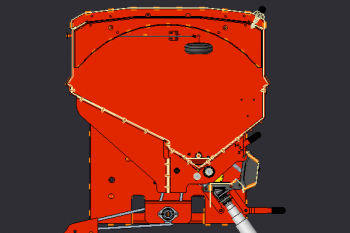

KUHN 9400NT no-till grain drills are designed for growers and custom operators sowing cereal grains, legumes and cover crops.

KUHN 9400NT grain drills are specifically designed for no-till applications, but have the ability to quickly adjust to conventional tillage conditions. Designed with innovative features like heavy-duty PRO openers and simplified, quick adjustments for seeding rates, operators get precise seed placement and maximum productivity. KUHN’s proven Helica meter design, combined with smooth drop tubes and standard seed agitator, provides a steady flow of seed and minimizes pulsing when planting. With three hopper configurations available (seed only, seed and fertilizer, and seed and seed), the 9400NT is versatile and can be suited to fit your operation’s needs. ISOBUS compatibility is available and helps monitor critical grain drill functions along with alerting the operator to any machine malfunctions.

YOUR BENEFITS

EQUIPMENT

Additional Equipment for the 9400NT Grain Drills

Weigh Scales

Weigh scales allow for real time monitoring of the seed remaining in the tanks.

Rear Mounted Small Seed / Legume Box

On the 9400NT, capacity has been increased to ½ bu./ft. doubling the capacity of competitive mechanical grain drills. Rear mounted, the legume box is easily filled without having to reach over main hoppers. If not in use, you can disengage from main drives by simply removing a pin. Ribbed hoses are connected from the small seed meters to formed steel drop tubes that distribute seed directly ahead of the rear press wheels or hoses can be modified for broadcast seeding.

Double-Fold Hydraulic Row Markers

Double-fold hydraulic row markers mount to the rear, allowing visibility and unrestricted access to front drives, no-till coulters, hydraulics, and seed cups. The markers are also shear bolt protected and equipped with a 14” diameter blade with depth band.

Calibration Assistant

When equipped with the ISOBUS electronics package, the calibration assistant walks the operator through the calibration procedure to ensure that the drill is set to precisely deliver the required seed rate. First, a seed chart on the drill is used to determine the theoretical meter, Variator and seed gate settings for the given seed type and rate. The operator places the calibration trays provided below the metering units and rotates the crank a given number of turns. A light on the side of the drill illuminates to notify the operator that the required number of turns has been reached. The seed collected is weighed and the weight entered back into the monitor. The system then calculates the exact seed rate being achieved so that the operator can fine tune the adjustments. The entire calibration process can completed within a few minutes and with the drill static before even going to the field. Because seed is collected from all the metering unit outlets, absolute precision of seed rate is ensured.

Electronics Package

The 9400NT is ISOBUS compatible with compliant in-cab monitor. The terminal monitors seed shaft rotations, hopper seed level, field speed, acre meter and features a seed rate calibration assistant. The KUHN VT 30 monitor is available for non-ISOBUS compliant systems.

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com