XTend Your Vertical Tillage

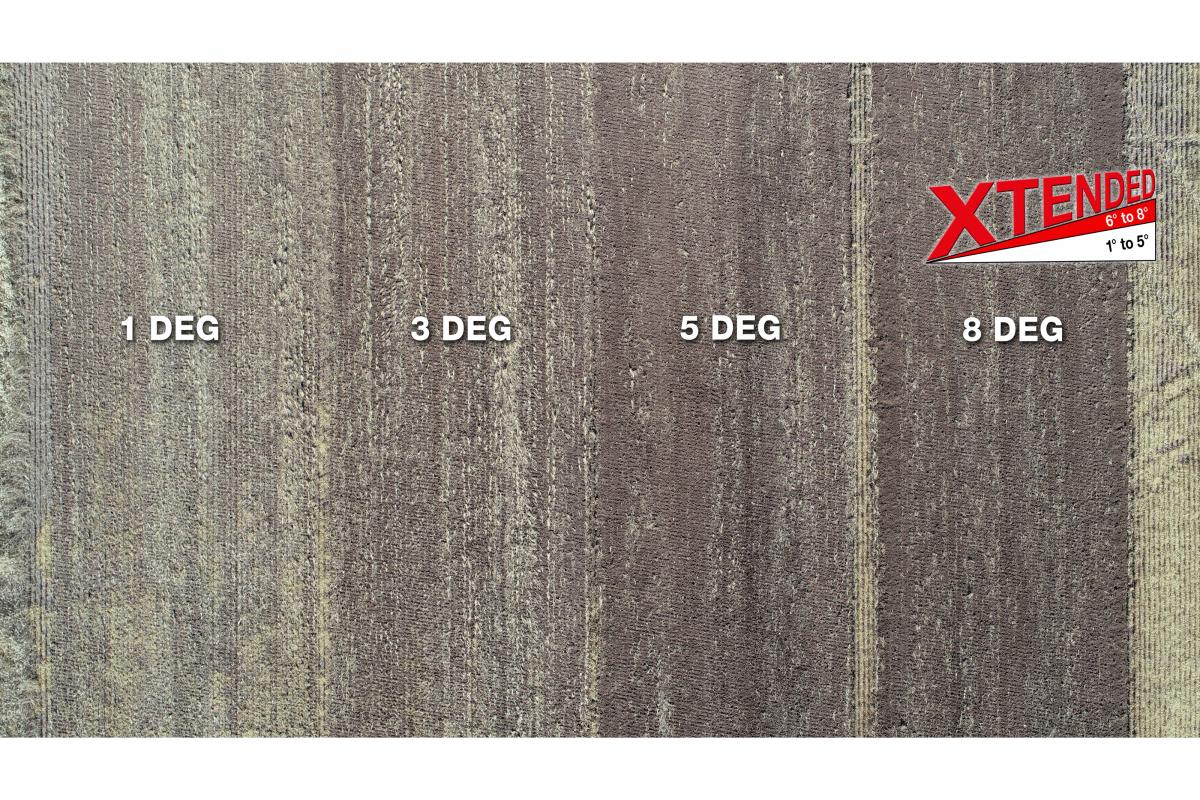

The Excelerator® XT 8010 provides XTended versatility. True vertical tillage is maintained with the 1° to 5° gang angle, while the XTended 6° to 8° gang angle offers more aggressive tillage action.

The KUHN Krause Excelerator® XT 8010 features the proven Excalibur® VT (vertical tillage) blades configured in a combination spacing (7″ front and 8″ rear) to meet the challenges of heavy GMO residue. New mid-mount tines control and redistribute residue followed by the exclusive Star Wheel™ treaders providing soil and residue mixing, clod size reduction and residue anchoring. Heavy-duty 24/7® conditioning reels provide that superior seedbed you have come to expect from the Excelerator.

YOUR BENEFITS

Exclusive 5-Step Process

Exclusive 5-Step Process

- Capture and Slice

Excalibur® VT (Vertical Tillage) blades, with their distinctive scalloped edge, capture and slice residue into planter-manageable sizes. This exclusive, 32-flute design easily penetrates soil, creates small clod size and begins the soil and residue mixing process. 7 inch blade spacing on front gang enhances optimal soil displacement. - Control and Distribute

Adjustable mid-mounted tines on 7 inch spacing drive soil and residue to ensure consistent flow of material. During this process, additional clod size reduction takes place, as well as improved residue distribution across the width of the operation, resulting in more consistent soil and residue conditions. - Cut and Remove

In this high-speed process, adjustable gang angles with Excalibur VT blades (on 8” spacing), remove the maximum amount of uncut soil at shallow depth settings, while minimizing furrowing and ridging for a smooth field finish. The adjustable gang angle gives you the choice to move soil laterally or to leave more residue. - Mix and Anchor

Exclusive to KUHN Krause, rotary Star Wheel™ treaders aggressively mix soil and residue, pulverize large clods, remove soil from disturbed root balls and anchor residue into the soil surface. - Size and Firm

The proven 24/7® soil conditioning reel delivers clod sizing and firming for this high-speed operation.

Manage Residue

Adjustable Gang Angles

True vertical tillage is maintained with the 1° to 5° gang angle, while the XTended 6° to 8° gang angle offers more aggressive tillage action. Optional on-the-go hydraulic adjustment allows the operator to adjust front and rear gangs on the same angle or independently, varying front to rear angles to match a variety of agronomic goals. These shallow angles prevent soil roll and inversion, distinguishing the Excelerator’s performance from competitive units based on older disc harrow technology with typical gang angles from 10° to 22°.

Excalibur® VT Blade Spacing

Proven 22″, 32-flute Excalibur® VT blades cut residue and maintain a sharp edge over time. The Excalibur blades are configured in a combination spacing with 7″ front spacing to enhance optimal soil displacement, while 8″rear spacing maintains performance in adverse conditions. The unique design of the Excalibur VT blades minimizes furrowing and ridging, leaving a smooth field pass-to-pass.

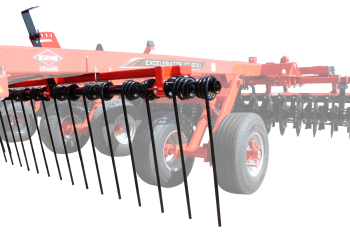

Mid-Mounted Tines

Adjustable mid-mounted tines on 7-inch spacing drive soil and residue to the ground to ensure consistent flow of material. During this process, additional clod size reduction takes place, as well as improved residue distribution across the width of the machine, resulting in more consistent soil and residue conditions.

Quality Finishing

Exclusive Star Wheel™ Treaders

Aggressively mix soil and residue, pulverize large clods, level and anchor residue into the soil surface. This action protects residue from blowing winds or washing rains, and begins the decomposition of residue into valuable organic matter.

The Star Wheel treaders assist in breaking out any remaining uncut soil between blade paths providing a smooth, even surface for planter row units to place seeds consistently in the seed zone. Constant flow hydraulic-adjustable gangs are spring cushioned to contour over varying field conditions, evenly distributing residue across the soil surface for a uniform finish.

Heavy-Duty 24/7® Conditioning Reel

The proven 24/7 soil conditioning reel delivers clod sizing and firming for this high-speed operation. The 24/7 reel also offers the convenience of “floating” with a simple in-field adjustment, allowing continued operation in higher soil moisture conditions. Two heavy-duty reel options are available. Choose flat blades for maximum clod sizing in hard soil conditions or round bars for increased soil firming in loamy soil conditions, this effective component completes a superior finish to any field.

EQUIPMENT

Star Wheel™ Hydraulics

Live hydraulic action keeps treaders in contact with soil contours maintaining uniform operational pressure across the width of the machine. This allows for superior soil leveling and residue mixing.

Hydraulic Wing Down Pressure

The Excelerator® features standard constant-flow hydraulic down pressure. This feature can add additional downforce to each wing via the wing fold cylinders. This feature stabilizes each wing section during high-speed operation.

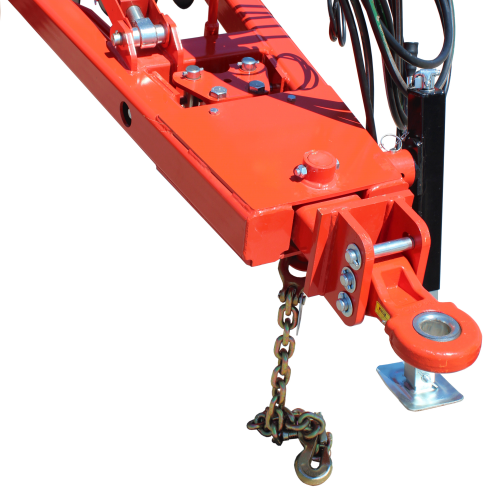

Guardian Hitch™

This exclusive option guards against stress on the tractor drawbar and implement frame. Lateral drawbar forces are transferred through the hitch pivot where shock load from steering input is dampened by urethane blocks. Choose from the articulating ball Cat III, IV or V double-bolt, cast hitch, depending on model.

Maintenance-Free Bearings

No daily grease maintenance required for the new PEER® TILLXTREME™ maintenance-free bearings, now incorporated into the Excalibur® VT gang assemblies, Star Wheel™ treaders and 24/7® conditioning reels. Spherical pivot bearing for each walking beam assembly requires no grease, along with rocker and wing hinge pivots.

Walking Beams

Standard heavy-duty walking beams on the center section feature heavy-duty wheel hubs, with “slip-in” spindles for easy servicing. Walking beam assemblies feature spherical pivot bearings requiring no daily grease maintenance. Walking beams on each wing have 6-bolt hubs, with bolt-in spindles as standard equipment.

Single-Point Depth Control

Blade depth is conveniently controlled with crank adjustable depth stop located at the front of the machine. View working depth on the easy-to-read scale.

Smart Soil Technology™

Available as an option on all folding Excelerator XT 8010 models (B Serial # and after), this ISOBUS control system allows adjustment of machine depth, front and rear gang angle, wing down pressure, Star Wheel™ pressure and front / rear leveling from any compatible ISOBUS display. ISOBUS equipment certified by the AEF is included in the online database. The customer can verify compatibility of ISOBUS functions between the machine and the terminal to be used. Learn more here

SPECIFICATIONS

| Transport Height |

|---|

| Transport Width |

| Blade Spacing |

| Number of Blades |

| Working Width |

| Gang Angle |

| Weight |

| 8010-11 | 8010-14 | 8010-20 | 8010-25 | 8010-30 | 8010-34 | 8010-40 |

|---|---|---|---|---|---|---|

| 6’5″ (2 m) | 6’5″ (2 m) | 10’9″ (3.2 m) | 12′ 8″ (3.8 m) | 13’0″ (4 m) | 14’9″ (4.5 m) | 12’6″ (3.8 m) |

| 12’8″ (3.8 m) | 15’4″ (4.7 m) | 12’3″ (3.7 m) | 12’3″ (3.7 m) | 15’9″ (4.8 m) | 18′ (5.5 m) | 19’3″ (5.9 m) |

| Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear | Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear | Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear | Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear | Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear | Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear | Combination 7″ (17.8 cm) Front 8″ (20.3 cm) Rear |

| 38 | 46 | 68 | 82 | 98 | 110 | 132 |

| 11′ (3.6 m) | 13’6″ (4.1 m) | 20′ (6.1 m) | 24’4″ (7.4 m) | 29’6″ (9 m) | 33’6″ (10.2 m) | 40’3″ (12.3 m) |

| Adjustable 1 to 8 Degrees | Adjustable 1 to 8 Degrees | Adjustable 1 to 8 Degrees | Adjustable 1 to 8 Degrees | Adjustable 1 to 8 Degrees | Adjustable 1 to 8 Degrees | Adjustable 1 to 8 Degrees |

| 9,820 lb (4 454 kg) | 11,800 lb (5 352 kg) | 17,750 lb (8 051 kg) | 20,500 lb (9 298 kg) | 25,760 lb (11 684 kg) | 30,859 lb (13 997 kg) | 35,760 lb (16 220 kg) |

| Hitch Type |

|---|

| Tongue Type |

| Hydraulics |

| Transport Locks and Safety |

| Excalibur® Blades |

| Gangs |

| Gang Angle Adjustment |

| Gauge Wheels |

| Fore / Aft Leveling |

| Main Frame Tires |

| Wing Frame Tires |

| Wing Fold Cylinders |

| Lift Cylinders |

| Mid Mount Tines |

| Star Wheel™ Treader Gang |

| 24/7® Conditioning Reel |

| Rear Hitch |

| 8010-11 | 8010-14 | 8010-20 | 8010-25 | 8010-30 | 8010-34 | 8010-40 |

|---|---|---|---|---|---|---|

| Combination CAT III – 1-1/2″ Pin and C Clevis – 1 1/4″ Pin | Combination CAT III – 1-1/2″ Pin and C Clevis – 1 1/4″ Pin | Articulating Ball, CAT IV, 2″ Pin | Articulating Ball, CAT IV, 2″ Pin | Articulating Ball, CAT IV, 2″ Pin | Articulating Ball, CAT IV, 2″ Pin | Articulating Ball, CAT IV, 2″ Pin |

| Mechanical Fore / Aft Adjustment, Level – Lift Tongue | Mechanical Fore / Aft Adjustment, Level – Lift Tongue | Mechanical Fore / Aft Adjustment, Level – Lift Tongue | Mechanical Fore / Aft Adjustment, Level – Lift Tongue | Mechanical Fore / Aft Adjustment, Level – Lift Tongue | Mechanical Fore / Aft Adjustment, Level – Lift Tongue | Guardian Hitch™ (Cushion Tongue) Level-Lift |

| Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

| Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting |

| Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades – 22″ Diameter, 6mm, 32-Flute, Reversed Crimped Center |

| 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾” Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms – C-Type 1-¼” x 2-½”, 6″ Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench |

| Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees |

| Not Applicable | Not Applicable | None | None | None | None | None |

| Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle |

| Walking Beams With Spherical Pivot Bearings, Slip-in Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 | Walking Beams With Spherical Pivot Bearings, Slip-in Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 340/60R16.5 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 340/60R16.5 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 380/55R16.5 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 440/55R18 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 440/55R18 |

| Not Applicable | Not Applicable | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (2) 340/60R16.5 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (4) |

| Not Applicable | Not Applicable | (2) 4″ x 40″ Adjustable Constant-Flow Hydraulic Down Pressure | (2) 4″ x 40″ Adjustable Constant-Flow Hydraulic Down Pressure | (4) 4″ x 40″ Adjustable Constant-Flow Hydraulic Down Pressure | (4) 4″ x 40″ Adjustable Constant-Flow Hydraulic Down Pressure | (4) 4″ x 40″ (4) 4-1/2″ x 16″ Adjustable Constant-Flow Hydraulic Down Pressure |

| (2) 4″ x 10″ | (2) 4″ x 10″ | Center: (2) 4″ x 10″ Wings: (2) 3-¾” x 10″ |

Center: (2) 4″ x 10″ Wings: (2) 3-¾” x 10″ |

Center: (2) 4 -¼” x 10″ Wings: (2) 4″ x 10″ |

Center: (2) 4 -¼” x 10″ Wings: (2) 4″ x 10″ |

Center: (2) 4-¼” x 10″ Inner Wing: (2) 4″ x 10″ Outer Wing: (2) 3-¾” x 10″ |

| 5/8″ x 27″ Tines on 7″ Spacing | 5/8″ x 27″ Tines on 7″ Spacing | 5/8″ x 27″ Tines on 7″ Spacing | 5/8″ x 27″ Tines on 7″ Spacing | 5/8″ x 27″ Tines on 7″ Spacing | 5/8″ x 27″ Tines on 7″ Spacing | 5/8″ x 27″ Tines on 7″ Spacing |

| 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings |

| Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings |

| None | None | None | None | None | None | None |

| Hitch Type |

|---|

| Tongue Type |

| Gang Angle Adjustment |

| Fore / Aft Leveling |

| Gauge Wheels |

| Gauge Wheels |

| Star Wheel™ Treaders |

| 24/7® Conditioning Reel |

| Rear Hitch |

| Smart Soil Technology |

| ISOBUS Terminal |

| ISOBUS Tractor Harness (ITH) |

| GPS Speed Sensor |

| Third Party GPS Harness |

| 8010-11 | 8010-14 | 8010-20 | 8010-25 | 8010-30 | 8010-34 | 8010-40 |

|---|---|---|---|---|---|---|

| Articulating Ball, CAT III 1-½” Pin | Articulating Ball, CAT III 1-½” Pin | Articulating Ball, CAT III 1-½” Pin | Not Applicable | Not Applicable | Articulating Ball, CAT V, 2-¾” Pin | Articulating Ball, CAT V, 2-¾” Pin |

| Not Applicable | Not Applicable | Not Applicable | Not Applicable | Guardian Hitch™ (Cushion Tongue) Level-Lift | Guardian Hitch™ (Cushion Tongue) Level-Lift | Not Applicable |

| Hydraulic Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees |

| Not Applicable | Not Applicable | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Not Applicable | Not Applicable | Not Applicable | (2) Front Castering 20.5″ x 8 Load Range E | (2) Front Castering 20.5″ x 8 Load Range E | (2) Front Castering 20.5″ x 8 Load Range E | (2) Front Castering 20.5″ x 8 Load Range E |

| Not Applicable | Not Applicable | Not Applicable | (2) Front Castering 20.5″ x 8 Kevlar | (2) Front Castering 20.5″ x 8 Kevlar | (2) Front Castering 20.5″ x 8 Kevlar | (2) Front Castering 20.5″ x 8 Kevlar |

| 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½” Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8″ Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings |

| Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings | Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings | Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings | Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings | Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings | Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings | Round Bar Spiral HD Reels, No-Daily Grease Maintenance Bearings |

| Extendable Tongue Rear Hitch: Max. 2,500 lb Tongue Weight and 10,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT | Extendable Tongue Rear Hitch: Max. 2,500 lb Tongue Weight and 10,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT | Extendable Tongue Rear Hitch: Max. 2,500 lb Tongue Weight and 10,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT | Extendable Tongue Rear Hitch: Max. 2,500 lb Tongue Weight and 10,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT | Extendable Tongue Rear Hitch: Max. 3,750 lb Tongue Weight and 15,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT | Extendable Tongue Rear Hitch: Max. 3,750 lb Tongue Weight and 15,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT | Extendable Tongue Rear Hitch: Max. 3,750 lb Tongue Weight and 15,000 lb Tow Weight with Hydraulic Remotes and Lighting Receptacle WITH & WITHOUT ATTACHMENT |

| N/A | N/A | In Cab ISOBUS Control of Depth, Gang Angle, Star Wheel™ Pressure, Wing Pressure & Front / Rear Leveling. Machines Equipped with Smart Soil Technology™ Require Total 3 Tractor SCVs. Smart Soil Technology™ Requires Max 4 GPM Oil Flow from Tractor. Requires 1 Free Flow Return to Tractor Reservoir (I.E. Motor Return). | In Cab ISOBUS Control of Depth, Gang Angle, Star Wheel™ Pressure, Wing Pressure & Front / Rear Leveling. Machines Equipped with Smart Soil Technology™ Require Total 3 Tractor SCVs. Smart Soil Technology™ Requires Max 4 GPM Oil Flow from Tractor. Requires 1 Free Flow Return to Tractor Reservoir (I.E. Motor Return). | In Cab ISOBUS Control of Depth, Gang Angle, Star Wheel™ Pressure, Wing Pressure & Front / Rear Leveling. Machines Equipped with Smart Soil Technology™ Require Total 3 Tractor SCVs. Smart Soil Technology™ Requires Max 4 GPM Oil Flow from Tractor. Requires 1 Free Flow Return to Tractor Reservoir (I.E. Motor Return). | In Cab ISOBUS Control of Depth, Gang Angle, Star Wheel™ Pressure, Wing Pressure & Front / Rear Leveling. Machines Equipped with Smart Soil Technology™ Require Total 3 Tractor SCVs. Smart Soil Technology™ Requires Max 4 GPM Oil Flow from Tractor. Requires 1 Free Flow Return to Tractor Reservoir (I.E. Motor Return). | In Cab ISOBUS Control of Depth, Gang Angle, Star Wheel™ Pressure, Wing Pressure & Front / Rear Leveling. Machines Equipped with Smart Soil Technology™ Require Total 3 Tractor SCVs. Smart Soil Technology™ Requires Max 4 GPM Oil Flow from Tractor. Requires 1 Free Flow Return to Tractor Reservoir (I.E. Motor Return). |

| N/A | N/A | CCI 800 or CCI 1200 Available as Option for Machines Equipped with Smart Soil Technology™. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have A Second ISOBUS Display In Cab. | CCI 800 or CCI 1200 Available as Option for Machines Equipped with Smart Soil Technology™. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have A Second ISOBUS Display In Cab. | CCI 800 or CCI 1200 Available as Option for Machines Equipped with Smart Soil Technology™. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have A Second ISOBUS Display In Cab. | CCI 800 or CCI 1200 Available as Option for Machines Equipped with Smart Soil Technology™. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have A Second ISOBUS Display In Cab. | CCI 800 or CCI 1200 Available as Option for Machines Equipped with Smart Soil Technology™. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have A Second ISOBUS Display In Cab. |

| N/A | N/A | ISOBUS Tractor Harness Available as Option for Machines Equipped with Smart Soil Technology™. Only Required for Use with Non-ISOBUS Tractors. | ISOBUS Tractor Harness Available as Option for Machines Equipped with Smart Soil Technology™. Only Required for Use with Non-ISOBUS Tractors. | ISOBUS Tractor Harness Available as Option for Machines Equipped with Smart Soil Technology™. Only Required for Use with Non-ISOBUS Tractors. | ISOBUS Tractor Harness Available as Option for Machines Equipped with Smart Soil Technology™. Only Required for Use with Non-ISOBUS Tractors. | ISOBUS Tractor Harness Available as Option for Machines Equipped with Smart Soil Technology. Only Required for Use with Non-ISOBUS Tractors. |

| N/A | N/A | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. |

| N/A | N/A | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where A Third Party GPS Unit Needs to Be Connected to the KUHN ITH Harness. Note: Additional Cables May Be Required From the GPS Manufacturer. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where A Third Party GPS Unit Needs to Be Connected to the KUHN ITH Harness. Note: Additional Cables May Be Required From the GPS Manufacturer. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where A Third Party GPS Unit Needs to Be Connected to the KUHN ITH Harness. Note: Additional Cables May Be Required From the GPS Manufacturer. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where A Third Party GPS Unit Needs to Be Connected to the KUHN ITH Harness. Note: Additional Cables May Be Required From the GPS Manufacturer. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where A Third Party GPS Unit Needs to Be Connected to the KUHN ITH Harness. Note: Additional Cables May Be Required From the GPS Manufacturer. |

| Recommended Operating Speed |

|---|

| Working Depth Range |

| Recommended Tractor Power |

| 8010-11 | 8010-14 | 8010-20 | 8010-25 | 8010-30 | 8010-34 | 8010-40 |

|---|---|---|---|---|---|---|

| 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) | 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) | 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) | 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) | 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) | 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) | 8 – 10 mph (12 – 16 km/h) Rocky Conditions: 6 – 8 mph (9 – 13 km/h) |

| 1″ – 3.5″ (2.5 – 8.9 cm) | 1″ – 3.5″ (2.5 – 8.9 cm) | 1″ – 3.5″ (2.5 – 8.9 cm) | 1″ – 3.5″ (2.5 – 8.9 cm) | 1″ – 3.5″ (2.5 – 8.9 cm) | 1″ – 3.5″ (2.5 – 8.9 cm) | 1″ – 3.5″ (2.5 – 8.9 cm) |

| 11 – 15 ENG HP/ft (26 – 37 kW/m) | 11 – 15 ENG HP/ft (26 – 37 kW/m) | 11 – 15 ENG HP/ft (26 – 37 kW/m) | 11 – 15 ENG HP/ft (26 – 37 kW/m) | 11 – 15 ENG HP/ft (26 – 37 kW/m) | 11 – 15 ENG HP/ft (26 – 37 kW/m) | 11 – 15 ENG HP/ft (26 – 37 kW/m) |

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com