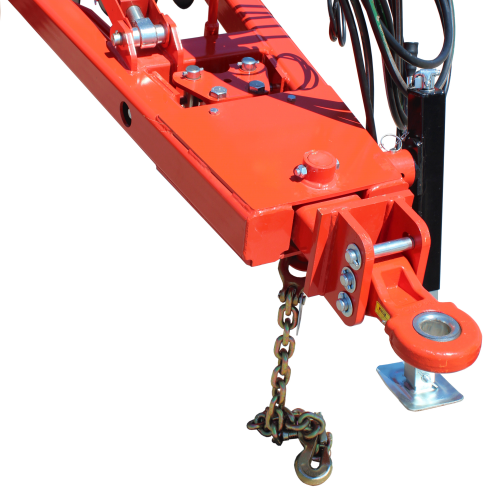

| CAT IV Articulating Ball Hitch for 2″ Pin |

CAT IV Articulating Ball Hitch for 2″ Pin |

CAT IV Articulating Ball Hitch for 2″ Pin |

CAT IV Articulating Ball Hitch for 2″ Pin |

| Mechanical Adjustable, Self-Leveling Tongue |

Mechanical Adjustable, Self-Leveling Tongue |

Guardian Hitch™ (Cushion Tongue) |

Guardian Hitch™ (Cushion Tongue) |

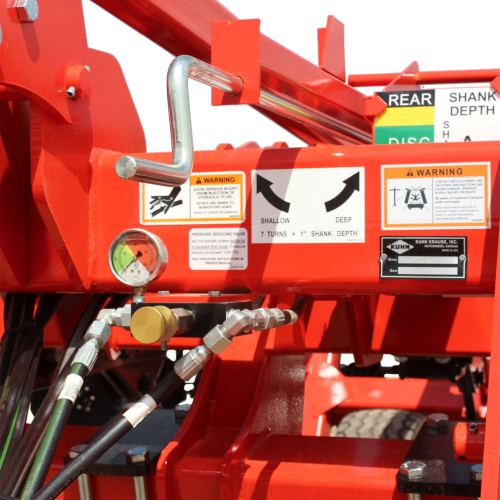

| Single Point Hydraulic Depth Control |

Single Point Hydraulic Depth Control |

Single Point Hydraulic Depth Control |

Single Point Hydraulic Depth Control |

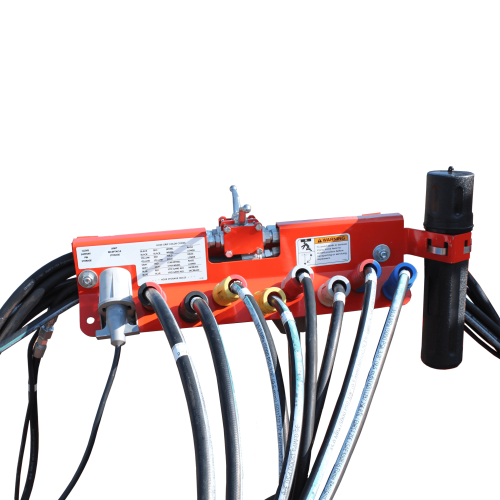

| Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

| 25″ x ¼” Smooth |

25″ x ¼” Smooth |

25″ x ¼” Smooth |

25″ x ¼” Smooth |

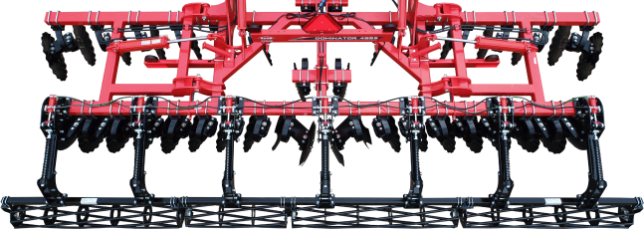

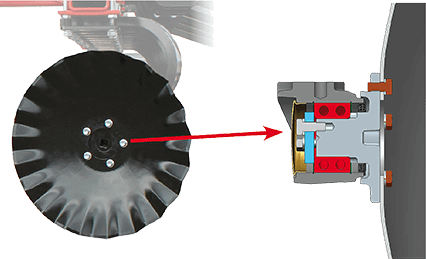

| 9″ Spacing, Adjustable Constant Flow Hydraulic, Heavy-Duty 6″ Bell Diameter Ductile Iron Spools, 1-¾” Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼” x 2-½” |

9″ Spacing, Adjustable Constant Flow Hydraulic, Heavy-Duty 6″ Bell Diameter Ductile Iron Spools, 1-¾” Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼” x 2-½” |

9″ Spacing, Adjustable Constant Flow Hydraulic, Heavy-Duty 6″ Bell Diameter Ductile Iron Spools, 1-¾” Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼” x 2-½” |

9″ Spacing, Adjustable Constant Flow Hydraulic, Heavy-Duty 6″ Bell Diameter Ductile Iron Spools, 1-¾” Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼” x 2-½” |

Combination (3) Spring Reset Parabolic Sub-Soil Shanks,

3000lb Point Load,

1-¼” x 4″ Shank with Wear Bar,

22″ Trip Height,

39″ Underframe Clearance,

16″ Working Depth and (4) Heavy-Duty Chisel Shanks,

1200lb Point Load,

1-¼” x 3″ Shank with Wear Bar,

21″ Trip Height,

37″ Underframe Clearance, 12″ Working Depth |

Combination (5) Spring Reset Parabolic Sub-Soil Shanks,

3000lb Point Load,

1-¼” x 4″ Shank with Wear Bar,

22″ Trip Height,

39″ Underframe Clearance,

16″ Working Depth and (4) Heavy-Duty Chisel Shanks, 1200lb Point Load,

1-¼” x 3″ Shank with Wear Bar,

21″ Trip Height,

37″ Underframe Clearance,

12″ Working Depth |

Combination (5) Spring Reset Parabolic Sub-Soil Shanks,

3000lb Point Load,

1-¼” x 4″ Shank with Wear Bar,

22″ Trip Height,

39″ Underframe Clearance,

16″ Working Depth and (6) Heavy-Duty Chisel Shanks, 1200lb Point Load,

1-¼” x 3″ Shank with Wear Bar,

21″ Trip Height,

37″ Underframe Clearance,

12″ Working Depth |

Combination (7) Spring Reset Parabolic Sub-Soil Shanks, 3000lb Point Load, 1-¼” x 4″ Shank with Wear Bar, 22″ Trip Height, 39″ Underframe Clearance, 16″ Working Depth and (6) Heavy-Duty Chisel Shanks, 1200lb Point Load, 1-¼” x 3″ Shank with Wear Bar, 21″ Trip Height, 37″ Underframe Clearance, 12″ Working Depth |

| Double K® Cast Chromium Carbide, 7″ Wing Ripper Point |

Double K® Cast Chromium Carbide, 7″ Wing Ripper Point |

Double K® Cast Chromium Carbide, 7″ Wing Ripper Point |

Double K® Cast Chromium Carbide, 7″ Wing Ripper Point |

| (4) 12.5L x 16 14-Ply, Walking Beams, Slip-In Spindles 8-Bolt Heavy-Duty Hubs |

(4) 12.5L x 16 14-Ply, Walking Beams, Slip-In Spindles 8-Bolt Heavy-Duty Hubs |

(4) 360/65R17.5, Walking Beams, Slip-In Spindles 8-Bolt Heavy-Duty Hubs |

(4) 360/65R17.5, Walking Beams, Slip-In Spindles 8-Bolt Heavy-Duty Hubs |

| Not Applicable |

Not Applicable |

(1) 9.5L x 15″ 8-Ply per Wing 6-Bolt Heavy-Duty Bolts |

(1) 9.5L x 15″ 8-Ply per Wing 6-Bolt Heavy-Duty Bolts |

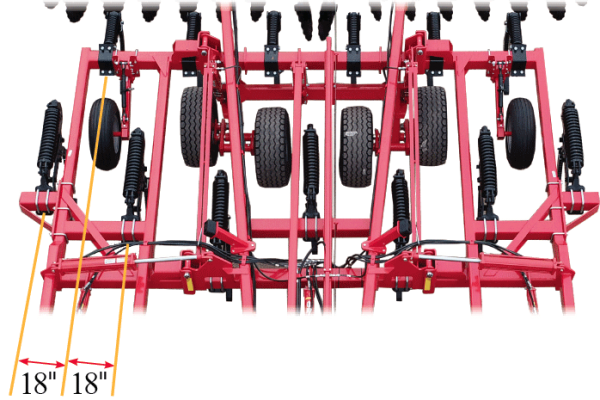

Front Beam: 24″ x 6 Gauge, Fluted Disc Blades, 18″ Blade Spacing

Rear Beam: 24 x 6 Gauge, Fluted Disc Blades and Smooth Taper Blades, 12″ Blade Spacing

Rear Beam: Center-Mounted 4-Lobe Feathering Blades |

Front Beam: 24″ x 6 Gauge, Fluted Disc Blades, 18″ Blade Spacing

Rear Beam: 24 x 6 Gauge, Fluted Disc Blades and Smooth Taper Blades, 12″ Blade Spacing

Rear Beam: Center-Mounted 4-Lobe Feathering Blades |

Front Beam: 24″ x 6 Gauge, Fluted Disc Blades, 18″ Blade Spacing

Rear Beam: 24 x 6 Gauge, Fluted Disc Blades and Smooth Taper Blades, 12″ Blade Spacing

Rear Beam: Center-Mounted 4-Lobe Feathering Blades |

Front Beam: 24″ x 6 Gauge, Fluted Disc Blades, 18″ Blade Spacing

Rear Beam: 24 x 6 Gauge, Fluted Disc Blades and Smooth Taper Blades, 12″ Blade Spacing

Rear Beam: Center-Mounted 4-Lobe Feathering Blades |

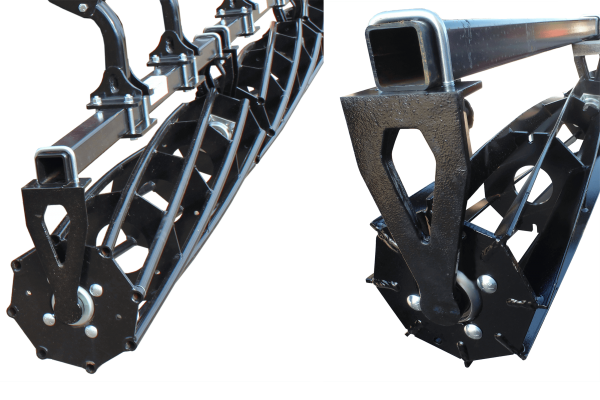

| 24/7® Soil Conditioning Reel, Heavy-Duty Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings |

24/7® Soil Conditioning Reel, Heavy-Duty Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings |

24/7® Soil Conditioning Reel, Heavy-Duty Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings |

24/7® Soil Conditioning Reel, Heavy-Duty Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings |

| (1) 2″ x 3.25″ Cylinder and Hoses per Carrier Arm |

(1) 2″ x 3.25″ Cylinder and Hoses per Carrier Arm |

(1) 2″ x 3.25″ Cylinder and Hoses per Carrier Arm |

(1) 2″ x 3.25″ Cylinder and Hoses per Carrier Arm |

| Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting |

Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting |

Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting |

Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting |