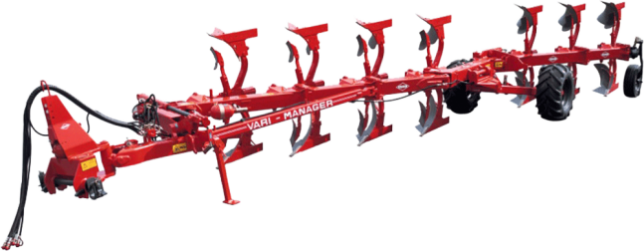

The All Arounder

For operators plowing hilly or undulating terrain, the semi-mounted Vari-Manager plow provides exceptional ground following due to its articulated design. Operators can pull more bottoms with the same horsepower tractor than if they were using a mounted plow.

With a wide choice of bottoms and trash burial options, KUHN Vari-Manager semi-mounted plows are suited for medium range horsepower tractors and working conditions. These plows are available as a hydraulically adjustable cutting width Vari-Manager that can be adjusted from the cab.

YOUR BENEFITS

EQUIPMENT

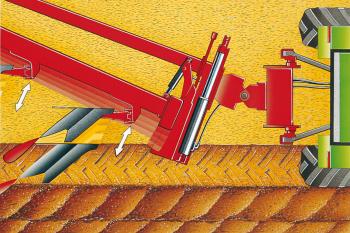

Depth and Transport Wheels

The 20” steel or 24” rubber wheel follows any change of plowing widths and features simple depth adjustment by screw adjuster, with the possibility of setting left and right sides differently. It can be placed in many locations on the frame to ensure optimum positioning for all conditions.

Rear Depth Control Wheel

Fitted with a 27” tire, the rear beam mounted depth wheel pivots freely from side-to-side to follow all changes in working width. The wheel is simply designed and easy to adjust. Depth adjustments are easy to execute by turning the handle screw with the possibility to set the depth independently left from right.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com