Highly Adaptable to Specific Field Conditions

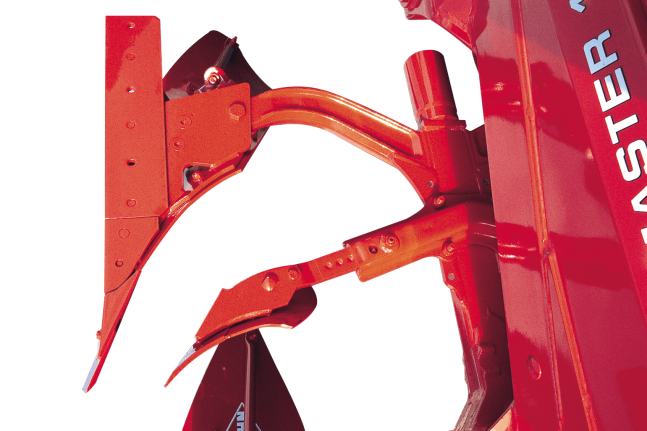

Today’s crop operations need a versatile plow to meet their conditions. Vari-Master plow Series operators have highly adaptable machines with heavy-duty components, a variety of options to choose from to suit their farming environment and can easily make adjustments from the cab.

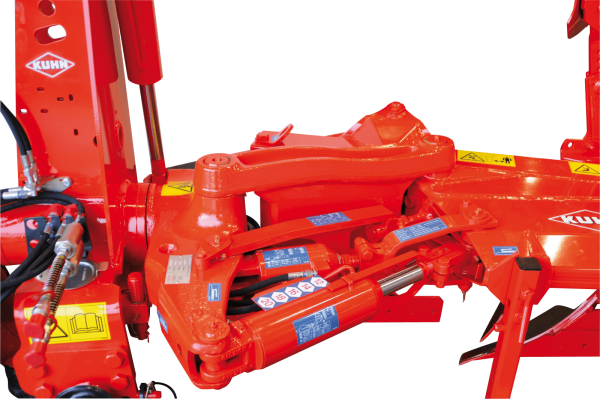

The KUHN Vari-Master plow series meets the demands of today’s row-crop and specialty farms. You won’t have to stop plowing with the non-stop hydraulic auto-reset system, which provides complete and continuous protection of the plow leg. Vari-Master plows are highly adaptable to specific field conditions. The quick set up into work/transport positions, easy adjustments and variable working widths help you cover more acres in less time.

YOUR BENEFITS

EQUIPMENT

Hydraulic Offsetting

Allows adjustment of the front furrow width from the tractor seat.

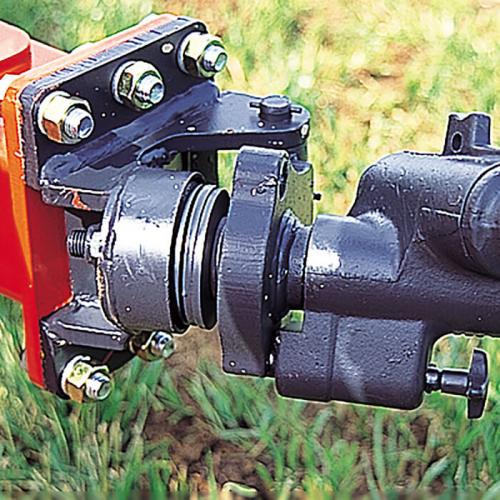

High Floating Depth Wheel with Shock Absorber

The shock absorber removes the shock of the wheel falling during rollover and also ensures the wheel is in the correct rearward inclined position as the plow is lowered back into work.

Standard Rubber Depth Wheel

The depth wheel follows any change of plowing width. It features simple bolt adjustments with the ability to set left and right sides independently. It can be placed in many locations on the frame to ensure optimum positioning for all conditions.

Transport Wheel with Suspension

The plow can be transported on the road in complete safety thanks to a transport wheel, equipped with its own suspension system to protect the plow and tractor from transport shocks. The wheel can be swung into transport position in a single movement by pulling the locking pin.

SPECIFICATIONS

SPECIFICATIONS

Product specifications are based on published information at the time of publication.

Product specifications are subject to change without further notice.

Contact your local KUHN Dealer for more information.

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com