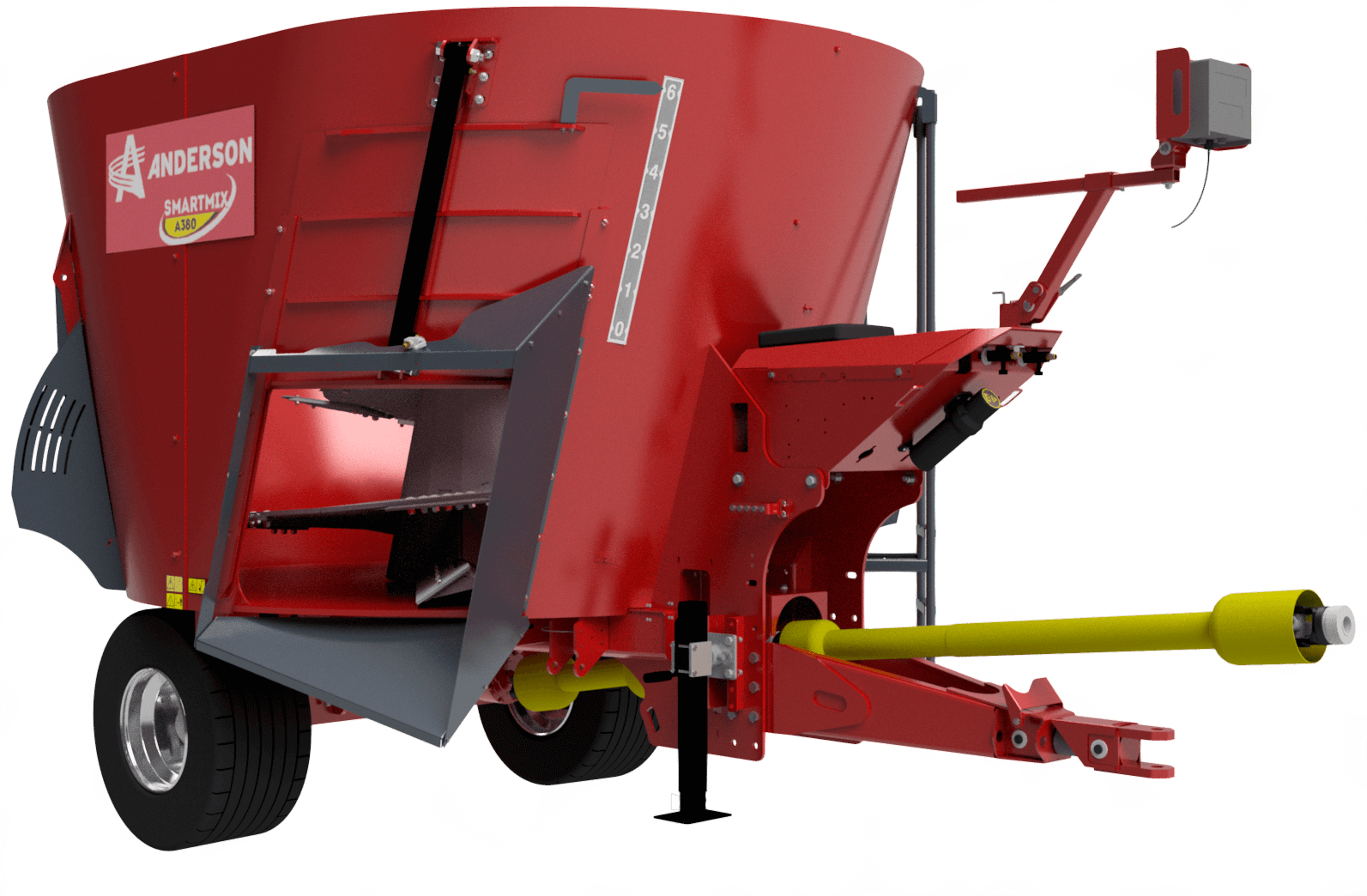

The Anderson pull type single auger A380 mixer (side trap discharge) with side trap discharge, will meet todays needs for high output and intensive use. It has been developed for farms where the footprint of the machine is an important factor. These mixers are compact and highly maneuvrable.

FEATURES & OPTIONS

- Capacity 380 pi3 à 490 pi3.

- Reinforced tub fl oor provides longevity of the tub and also to the load cells by equalizing the weight uniformly.

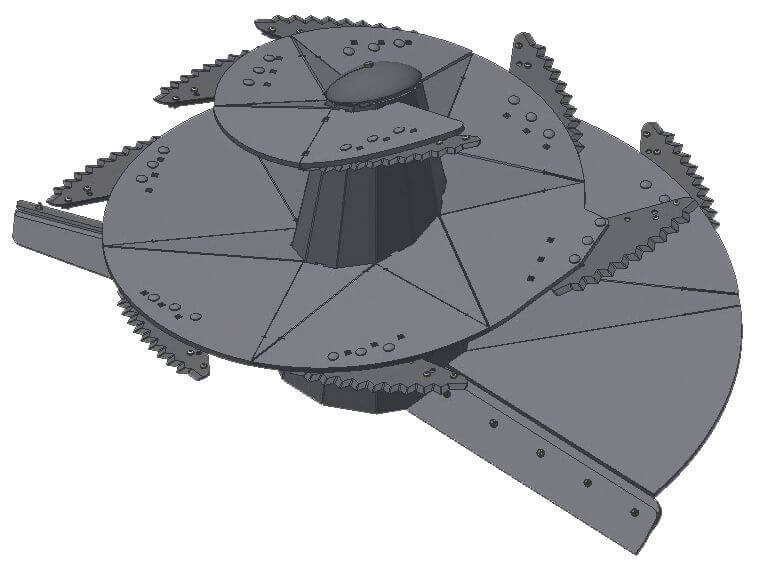

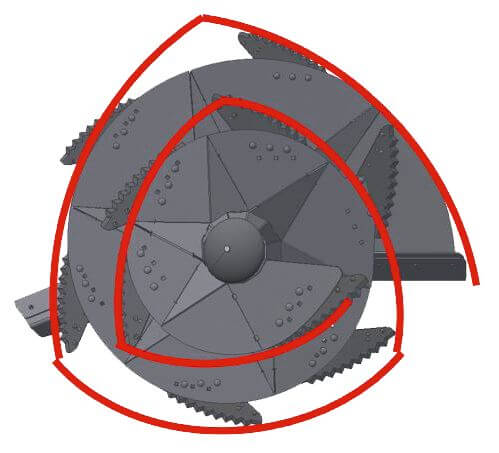

- TRI-CUT™, auger with 2-position adjustable and reversible knives (10 standard) and 2 sweeping dispensers ensuring a 30% faster and more consistent discharge.

- Discharge options: Side trap or front conveyor.

- Carbide treated self-sharpening tungsten knives.

- Industry’s fi rst hydraulic TRUE-CUT™ restrictor blades allows the operator to engage and disengage during the mixing process preventing all risks of overprocessing feed.

- The DG500 indicator is a universal, programmable weighing indicator for recipes, dispensing and data storage. It guarantees an extremely precise weighing thanks to the protected load cells and strategically located under the tank. Compatible with the DTM suite.

- 3-point scale system.

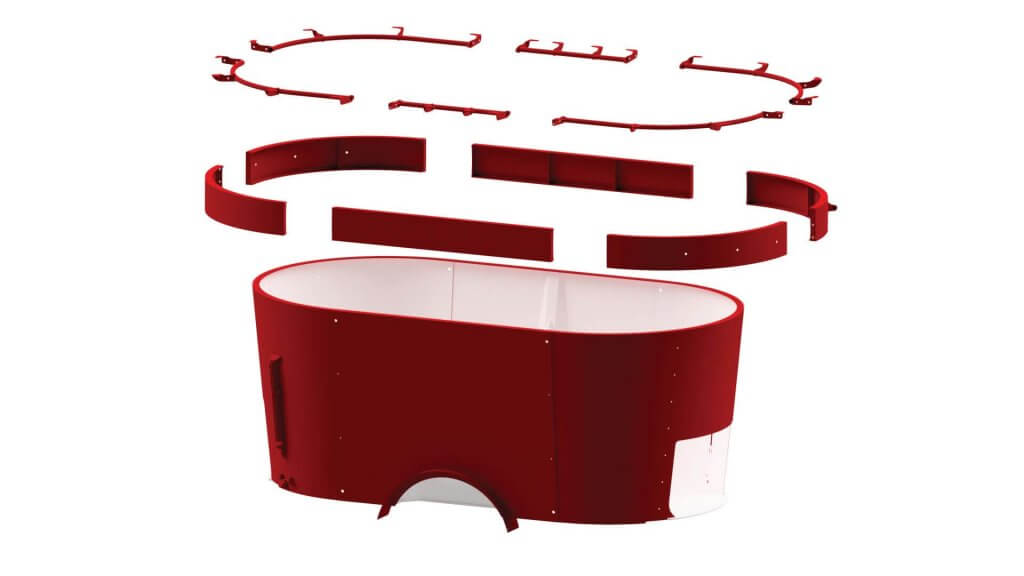

- Rolled side walls (not bent) for better fl ow of material, avoiding restriction around auger and naturally increased sturdiness.

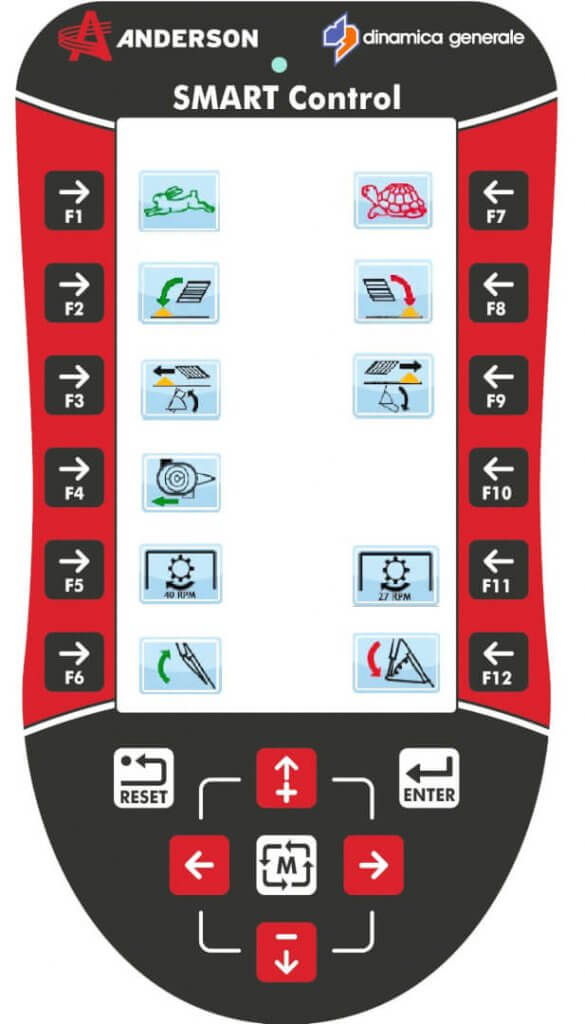

- SMART CONTROL remote control (optional) provides you full wireless control to: customize weighing system and recipe, hydraulics, speed of belt etc.

- Optional 2 speed gearbox.

SPECIFICATIONS

| Capacity (no capacity extension) | 380 ft3 (10.8 m3) |

| 6 in capacity extension | 420 ft3 (11.9 m3) |

| 12 in capacity extension | 460 ft3 (13 m3) |

| 18 in capacity extension | 500 ft3 (14.2 m3) |

| Number of Auger | 1 |

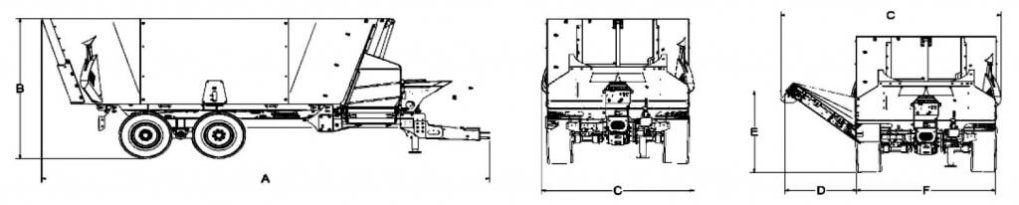

| Length (A) | 189 in (4.79 m) |

| Height (B) no extension | 106 in (2.69 m) |

| 6 in capacity extension | 112 in (2.84 m) |

| 12 in capacity extension | 118 in (3 m) |

| 18 in capacity extension | 124 in (3.15 m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Width (C) | |

| Without incline conveyor | 101 in (2.57 m) |

| With incline conveyor (retracted) | 117 in (2.97 m) |

| Incline conveyor operating angle (degrees) | 26 @39 degrees |

| Outside width of the wheels | 86 in (2.18 m) |

| Lateral distance to discharge point (D) | |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 30-23in at 26º / 27-20in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 41-45in at 26º / 52-52in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 48-52in at 26º / 63-63in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 53-57in at 26º / 69-69in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 60-64in at 26º / 79-79in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 64-68in at 26º / 85-85in at 40º |

| Discharge height (E) | |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 37-41in at 26º / 46-46in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 36 in (0.91 m) |

| PTO shaft – Standard specification | 540 RPM 1″ 3/8 Z6 |

| PTO shaft – Option specification | 1000 RP m 1″ 3/8 Z21 |

| 2 speed Gear Box | Optional |

| 2 Speed Gear Box and ratio | D732, 1;1,5 54in(888cm)0 RPM |

| Minimum PTO HP Requirement – Low Speed | 50 |

| Minimum PTO HP Requirement – High Speed | 75 |

| Auger RPM – Low Speed | 27 RPM |

| Auger RPM – Standard High speed | 41 RP M |

| Standard planetary model and ratio configuration | 1602 @13.4 |

| Optionnal Planetary | N/A |

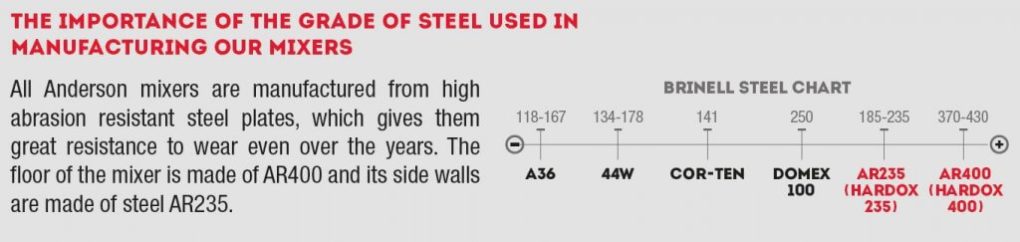

| Floor Thickness (AR235 grade or equivalent) | 3/4 in |

| Sidewall Thickness (AR235 grade or equivalent) | 1/4 in |

| Flighting Thickness (AR235 grade or equivalent) | 5/8 in |

| Standard knives per auger | 6 / 10 optional |

| Driveline security | Shear bolt |

| Hydraulic flow requirement | 10-15 US gal/ m in 37-56 L/ m in |

| Hydraulic pressure | 160-200 bar (2300-2900 psi) |

| Load cell | 3 |

| Scale system | DG500 (standard) |

| Machine Weight (empty) – STD configuration | 8465 lb (3839 kg) |

| Utility load capacity | 11 020 lb (4998 kg) |

| Axle – Standard specifications | Single |

| Axle – Optional specifications | N/A |

| Wheels – Standard specifications | 15.0/55-17 26 PLY |

MEDIA

Contact Us

Contact the Red Deer Hay Center

Phone: 403 340 1000

Hours or Operation

Monday to Friday: 8:30 PM to 5:00 PM

Saturday: 8:30 AM to 12: PM

Sunday: Closed

eMail : ed@haycenter.com